Later period sun curing method of cayenne pepper thick broad-bean sauce in plastic tent heliogreenhouse

A technology for solar greenhouse and bean paste, which is applied in the fields of food preparation, application, food science, etc., can solve the problems of long drying cycle, many labors, low labor efficiency, etc., and achieves low economical cost, easy temperature control, and flavor retention. constant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

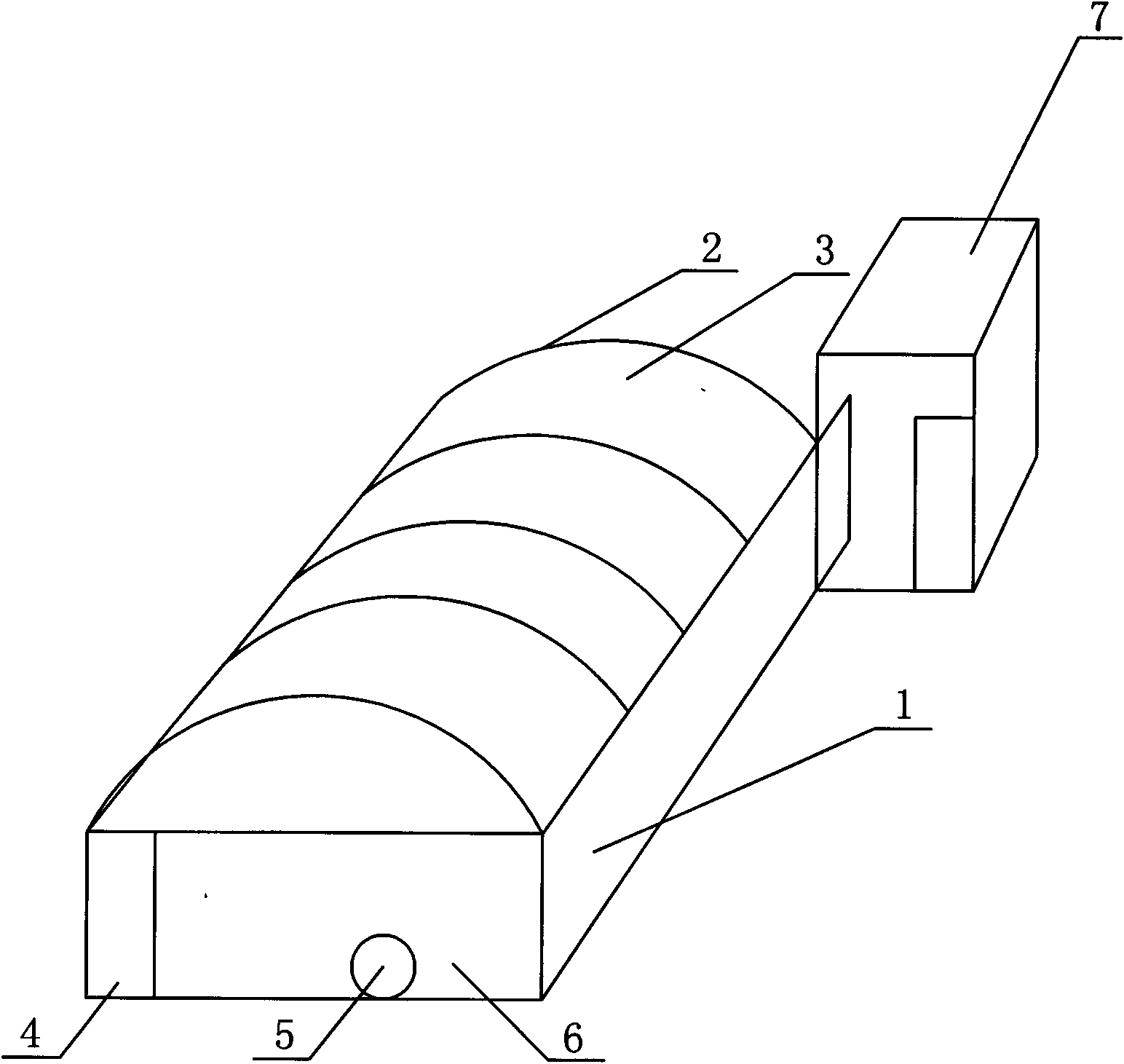

[0008] The greenhouse solar greenhouse of the present invention is further explained with reference to the accompanying drawings to the post-drying method of hot pepper bean paste: (A) the construction of the plastic greenhouse solar greenhouse adopts a rectangular greenhouse, and the long sides of the greenhouse are east-west Orientation, the length is not limited, generally 24-68 meters, the width is 6-10 meters, the highest point from the ground to the top of the shed is 2.5-2.8 meters, the side wall 1 of the side room is 1.2 meters high, (B) the arch shed 2 uses long bamboo pieces , small bamboo poles or stainless steel pipes, made into a semi-circular arched scaffold, the two ends of the arched scaffold 2 are fixed on the upper end of the side wall 1, and the plastic film 3 is covered and fixed on the large scaffold 2 with food-grade thick polyethylene plastic film bonding The upper end of the two end end walls 6 of the greenhouse greenhouse is made into a semicircular arc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com