Air Conditioner for Vehicle

a technology for air conditioners and vehicles, applied in vehicle heating/cooling devices, refrigerating machines, sorption machines, etc., can solve the problems of limited air blowing into the vehicle interior, difficult control of blower fan, and inability to send out uncomfortable cool air, etc., to achieve the effect of enhancing the rising speed of the interior temperatur

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

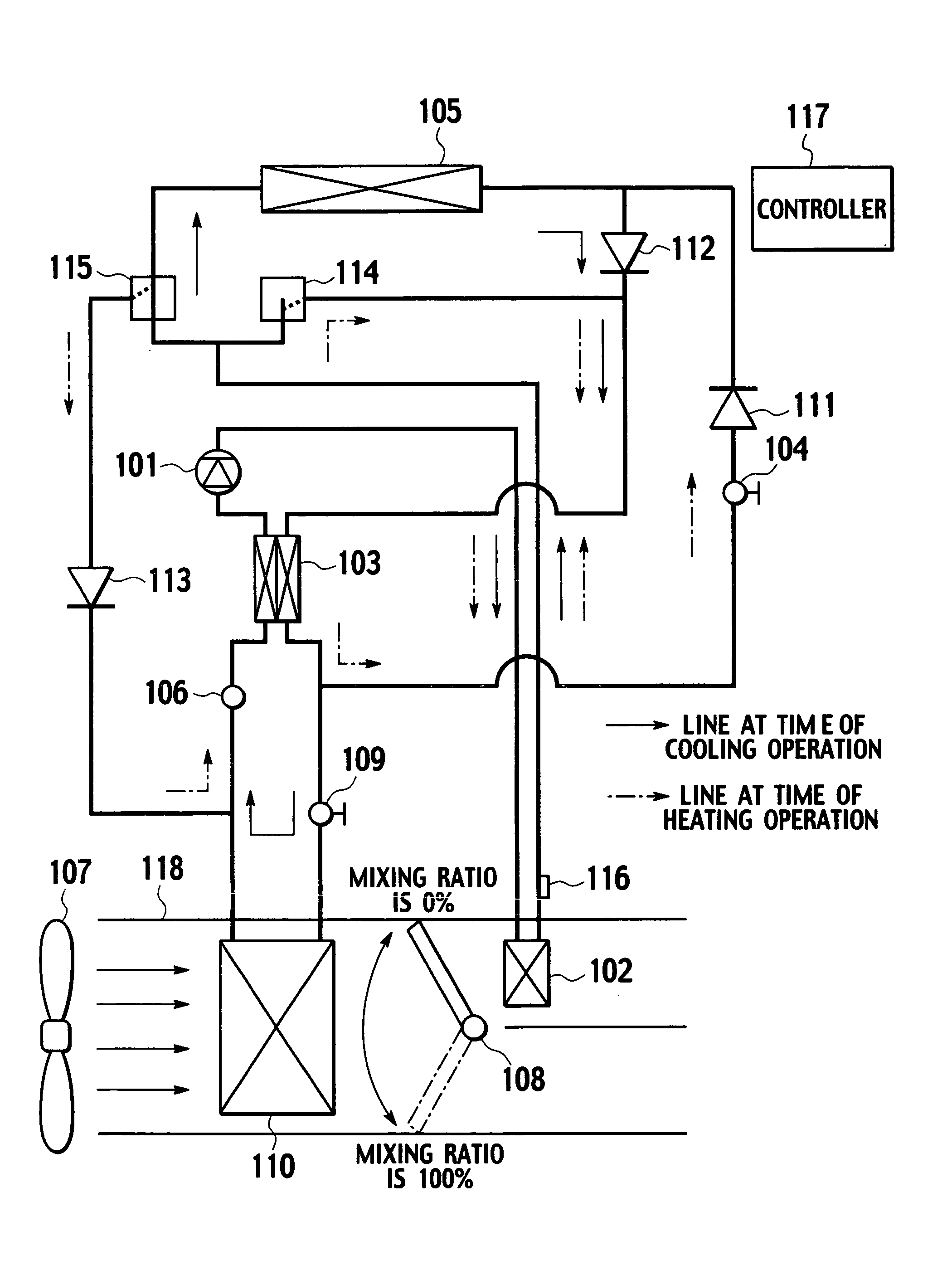

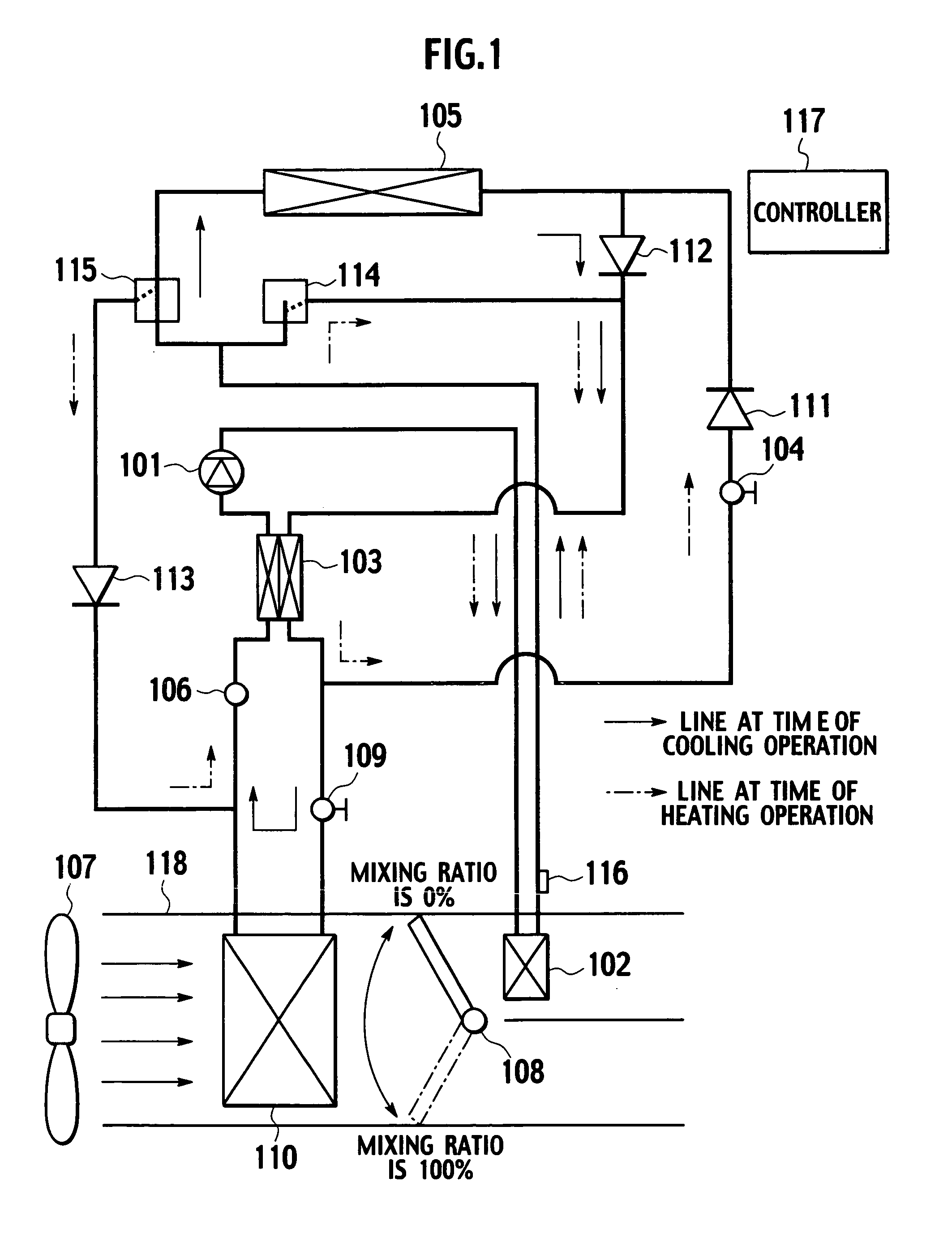

[0038]FIG. 1 is a schematic configuration diagram of an air conditioner for a vehicle according to a first embodiment.

[0039]An air conditioner for a vehicle which is applied to an electric car or the like, in which refrigerant is used as a heat source will be explained. The air conditioner for a vehicle of the embodiment includes a heating cycle (shown with -•-→in the drawing) which circulates carbon dioxide as the refrigerant to exchange heat between the refrigerant and air.

[0040]The heating cycle includes a compressor 101, a sub-heat exchanger 102 (internal heat exchanger 103), an expansion valve 104, an exterior heat exchanger 105, and an accumulator 106 that are communication-connected with one another through pipes in this order, and refrigerant compressed by the compressor 101 is circulated through these members.

[0041]The compressor 101 obtains a driving force from a motor (not shown) and compresses gas-phase carbon dioxide, and discharges the compressed carbon dioxide as high...

second embodiment

[0073]FIG. 8 is a schematic configuration diagram of an air conditioner for a vehicle according to a second embodiment. Like reference signs denote like parts as those shown in FIG. 1, and bold lines shows paths of the heating cycle, and broken lines show paths of the cooling cycle (explanation thereof is omitted).

[0074]The air conditioner for a vehicle of this embodiment is applied to an engine vehicle. Engine cooling water, carbon dioxide, and refrigerant are used as heat sources. The configuration of this embodiment can be applied to R134a refrigerant. In this case, the internal heat exchanger 103 is not a fundamental element.

[0075]According to the air conditioner for a vehicle of this embodiment, a heater core 119 is disposed in the air conditioner duct 118, and engine cooling water flowing through a cooling passage of an engine 120 is circulated through a pipe. The heater core 119 heats the air conditioner wind sent out from the blower fan 107 by the engine cooling water. A wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com