Wellhead isolation tool including an abrasive cleaning ring

a technology of cleaning ring and wellhead, which is applied in the direction of drilling casings, drilling pipes, borehole/well accessories, etc., to achieve the effect of promoting a better seal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

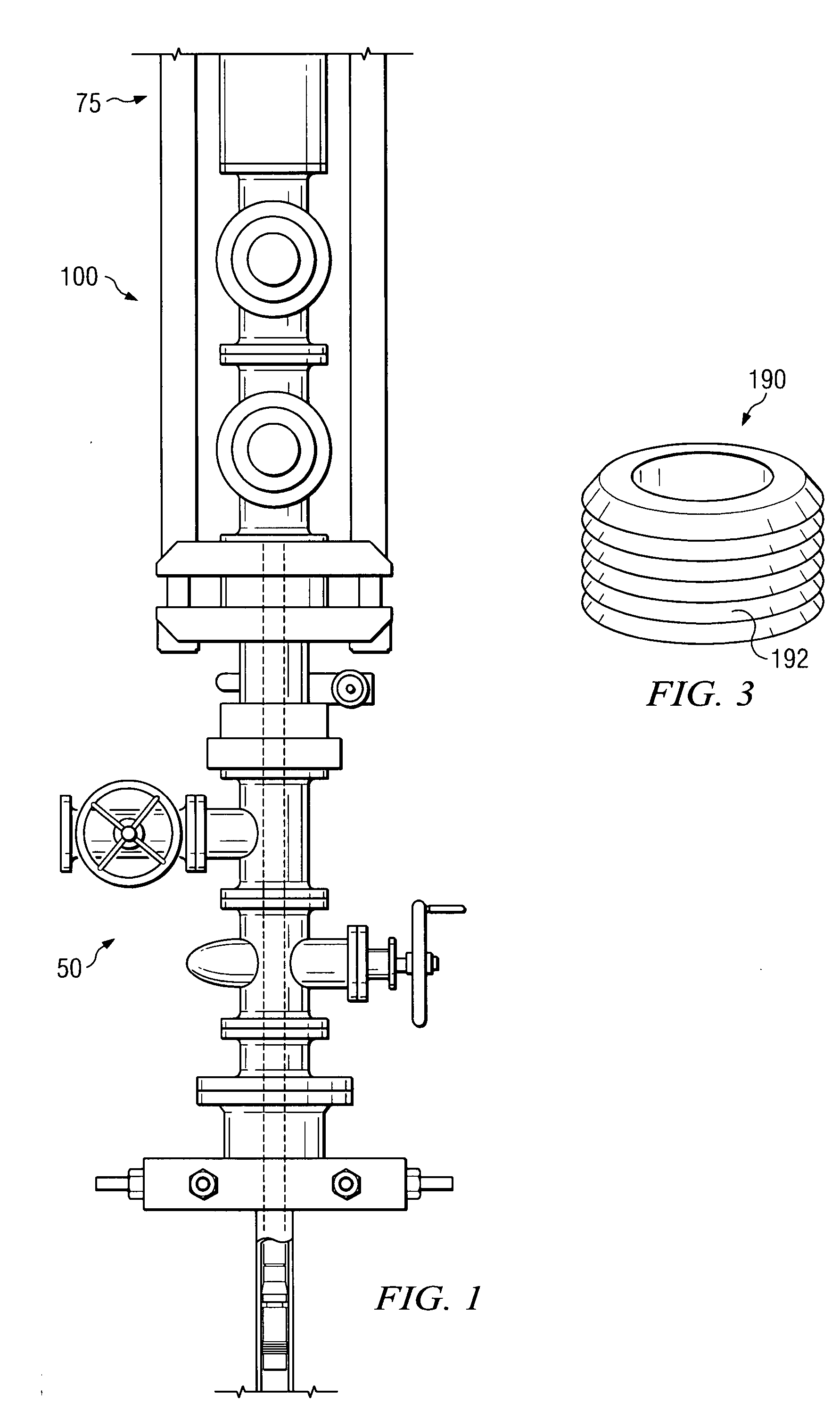

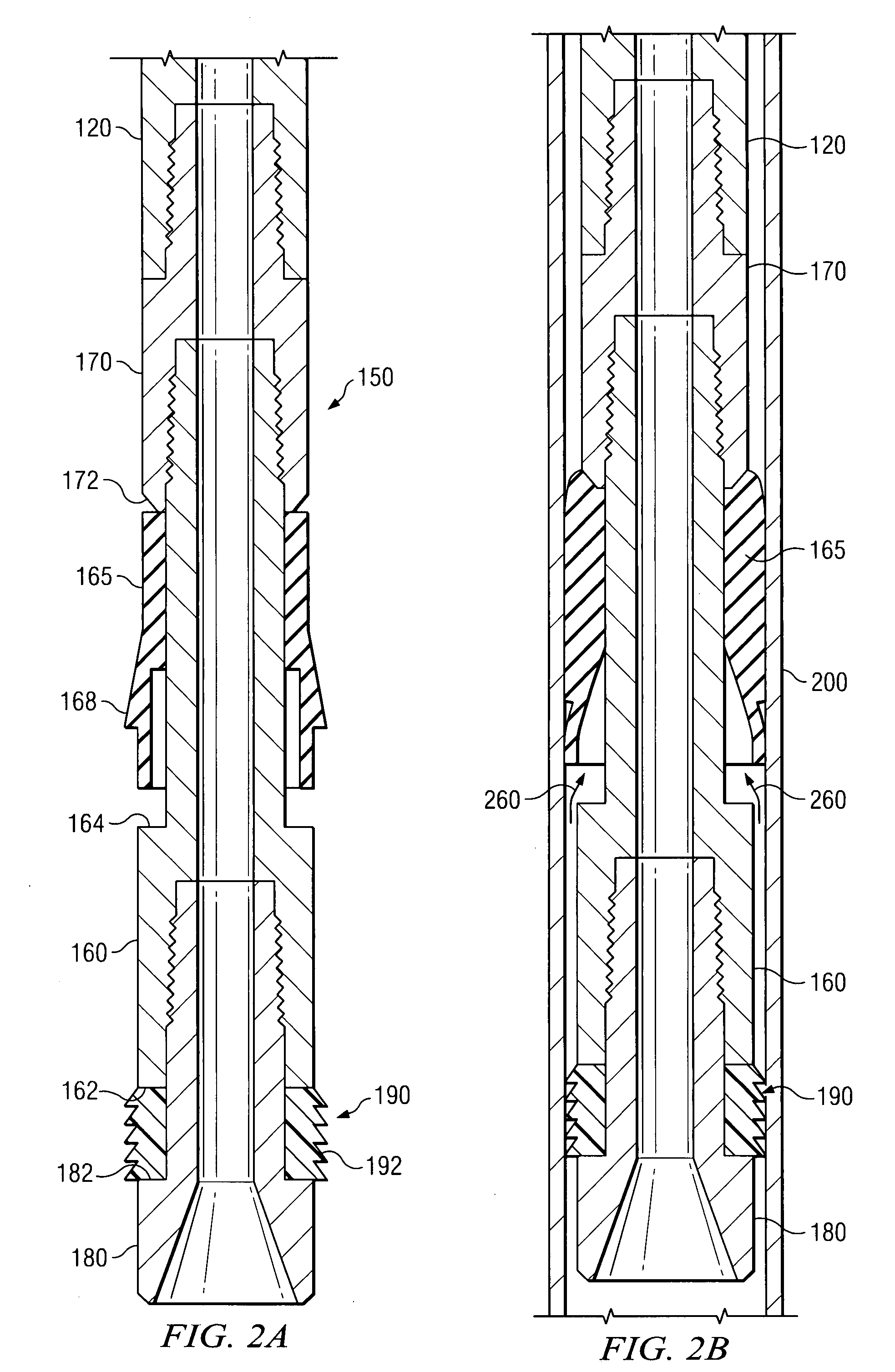

[0019]Referring to FIGS. 1 through 3, it will be understood that features or aspects of the embodiments illustrated may be shown from various views. Where such features or aspects are common to particular views, they are labeled using the same reference numeral. Thus, a feature or aspect labeled with a particular reference numeral on one view in FIGS. 1 through 3 may be described herein with respect to that reference numeral shown on other views.

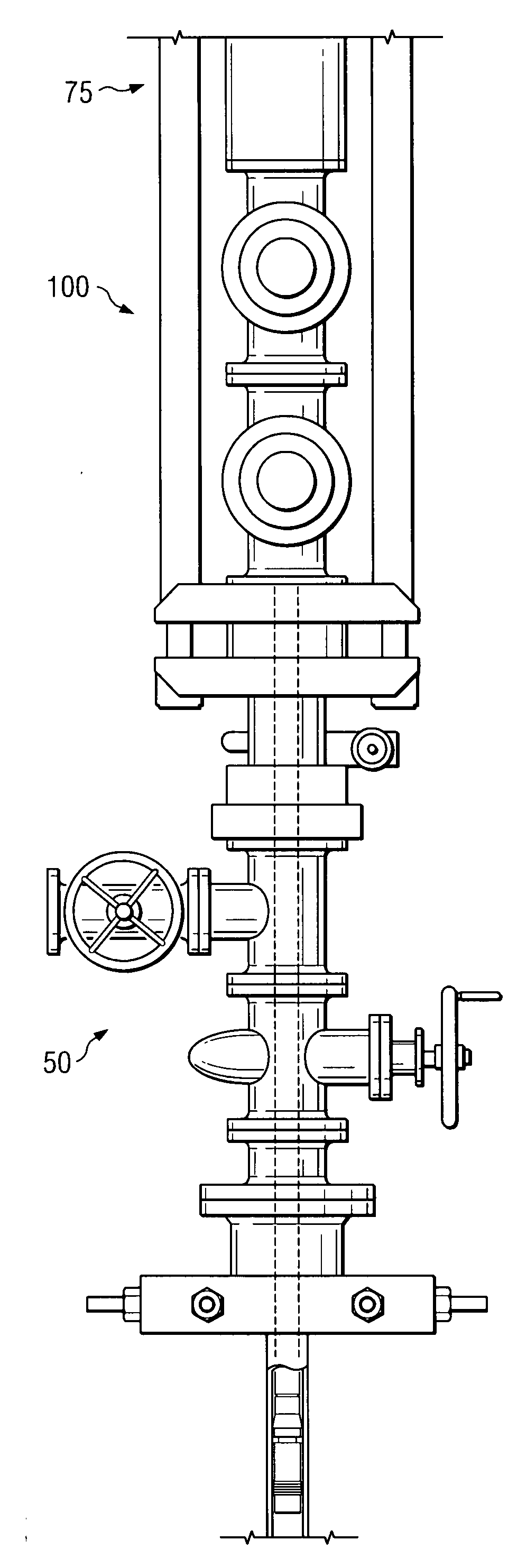

[0020]Referring now to FIG. 1, one exemplary embodiment of a wellhead isolation tool 100 in accordance with the present invention is shown deployed on a wellhead 50. Wellhead isolation tool 100 is shown deployed below a conventional frac head 75 and above the wellhead 50 (only a lower portion of the frac head is shown on FIG. 1). During a typical fracturing operation abrasive fluids are pumped under high pressure into the frac head 75, through the isolation tool 100, and down into the well. The isolation tool includes an inner mandrel 120 (s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com