Composite Carbon Fiber Bicycle Crank and Its Method of manufacture

a technology of composite carbon fiber and bicycle crank, which is applied in the direction of folding cycles, bicycle equipment, cycles, etc., can solve the problems of troublesome manufacturing of bicycle cranks b>92/b>

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

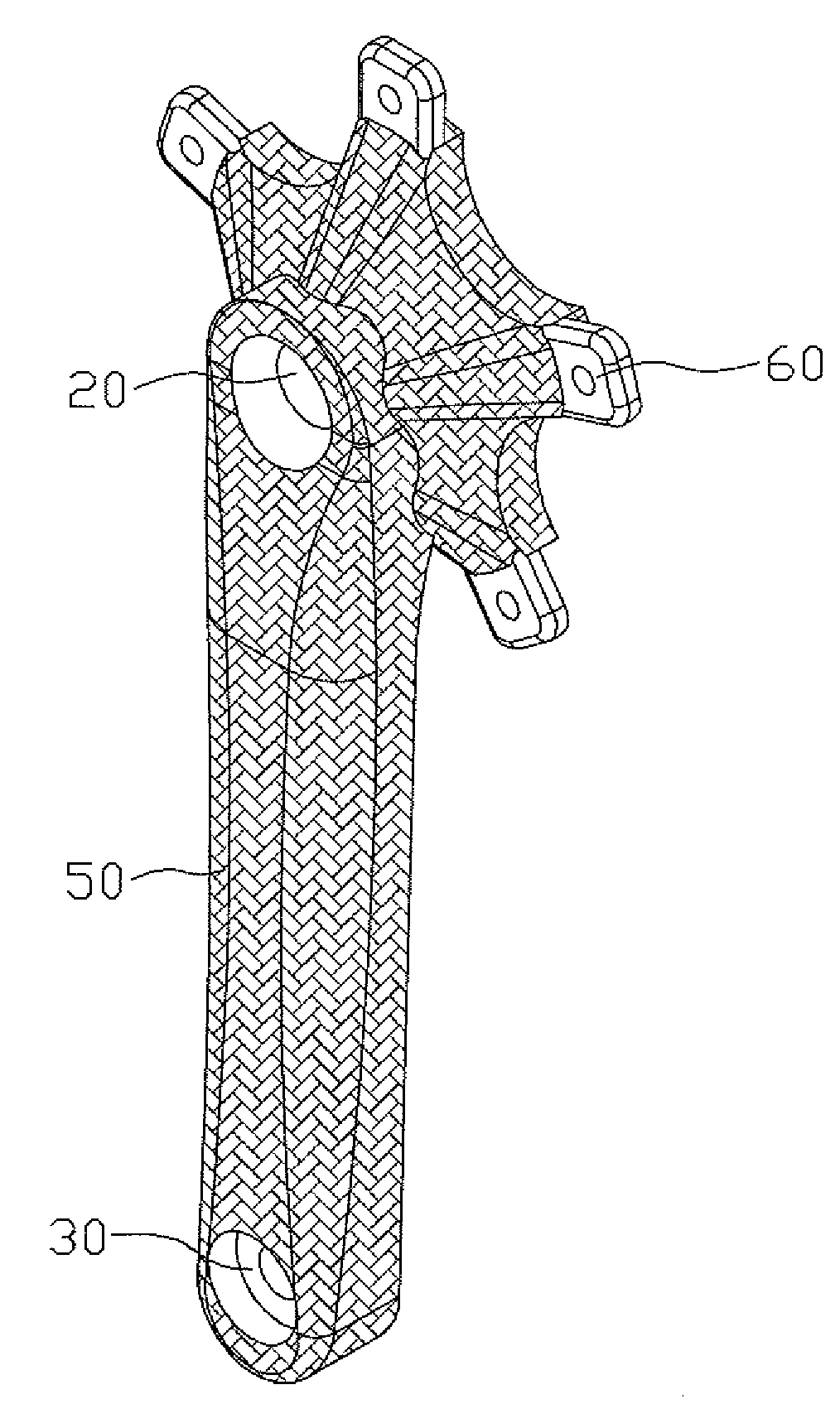

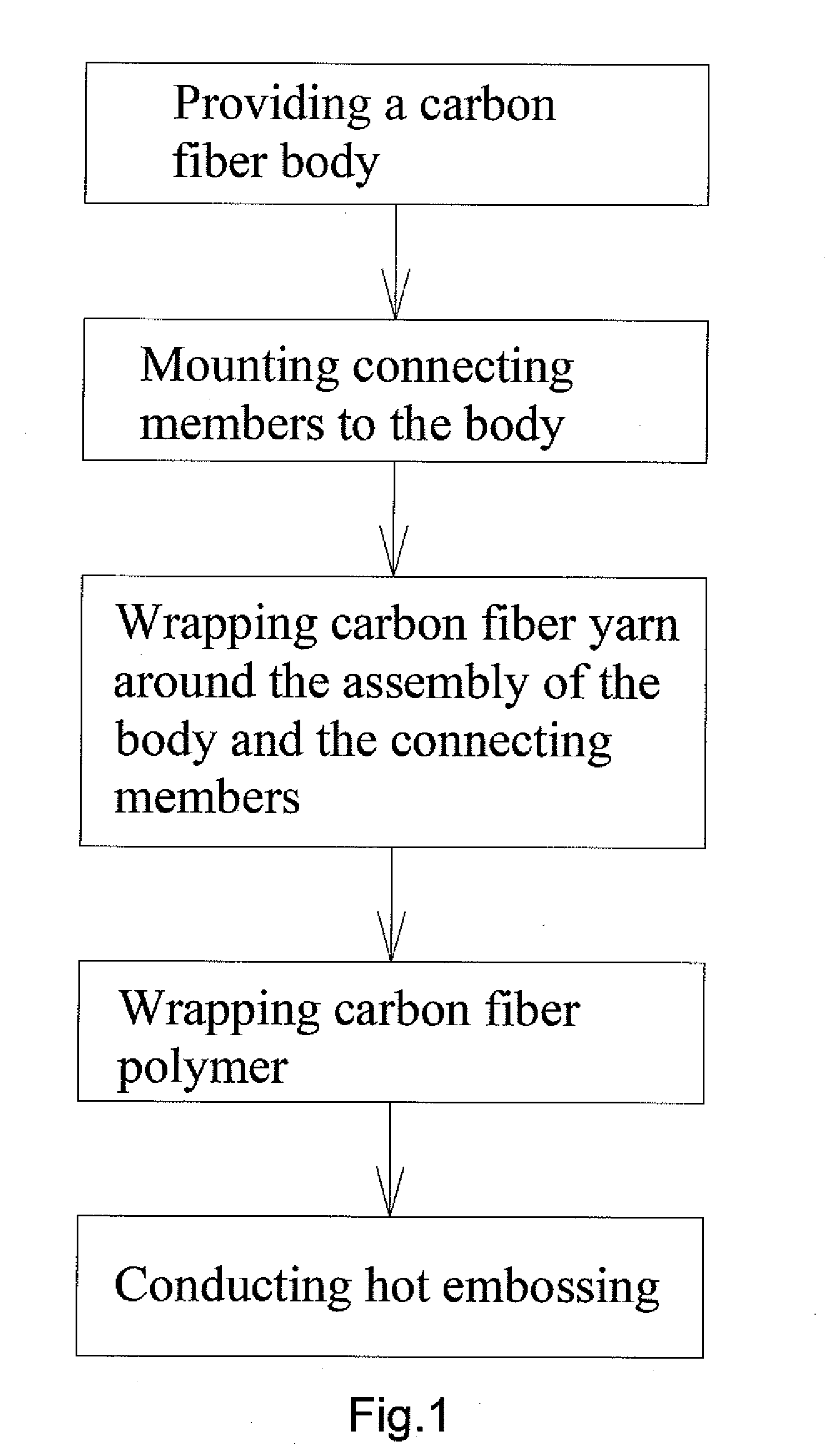

[0024]Referring to FIG. 1, there is shown a method of manufacture of a bicycle crank in accordance with the present invention. The method includes providing a body 10 made of carbon fiber, mounting a first connecting member 20 and a second connecting member 30 to the body 10, wrapping carbon fiber yarn 40 around the assembly of the body 10 and the first and second connecting members 20, 30, wrapping carbon fiber polymer 50, and conducting hot embossing.

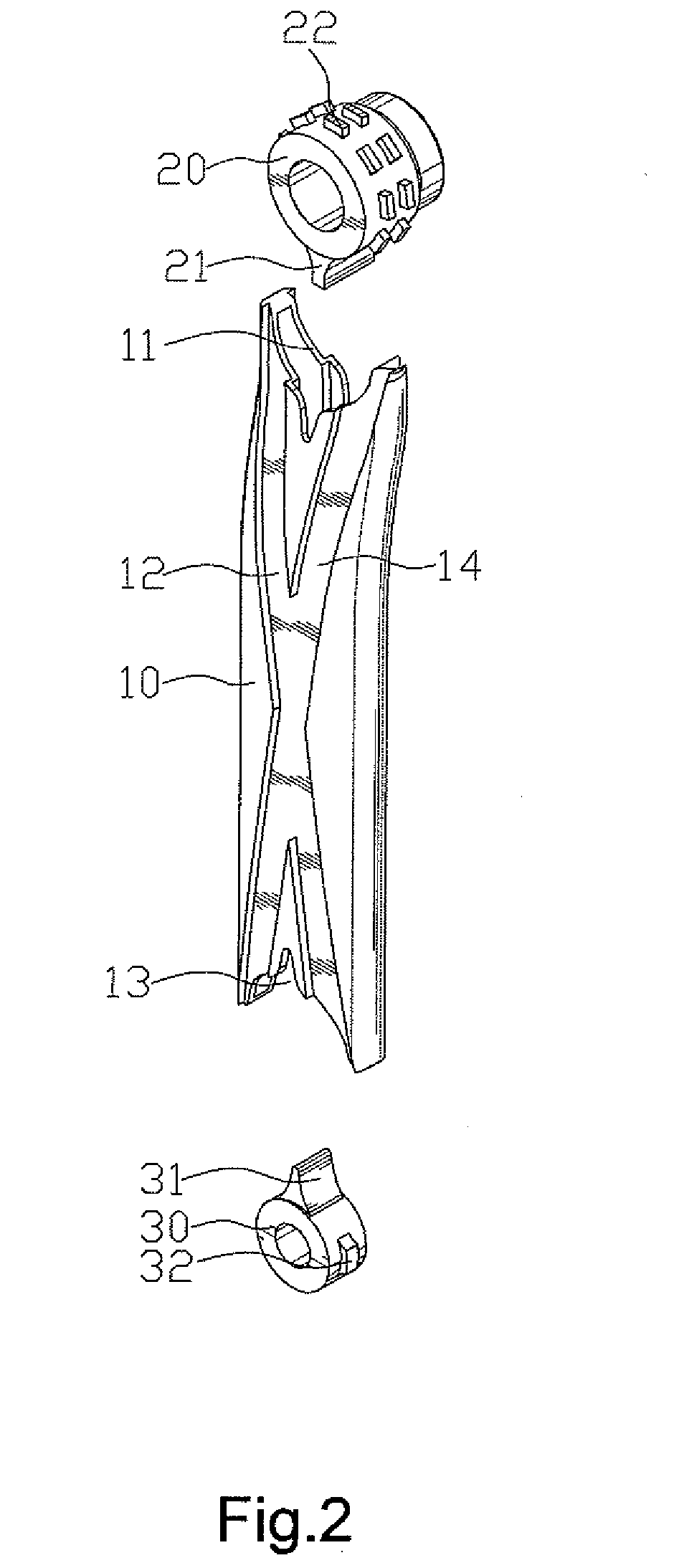

[0025]Referring to FIGS. 2 through 5, the body 10 is hollow and includes a first opening 11 at one end for receiving the first connecting member 20, a second opening 13 at another end for receiving the second connecting member 30. The body 10 also includes a first groove 12 and a second groove 14 recessed into the outer surface thereof, wherein the first and second grooves 12, 14 are intercrossed and both grooves extend from the first opening 11 to the second opening 13.

[0026]The first connecting member 20 and the second connecting me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com