Flexible draper and cutter bar with tilt arm for cutterbar drive

a cutterbar drive and flexible technology, applied in the field of harvesting headers, can solve the problems of ineffective flexible headers that include flexible cutterbars and ineffective handling of all severed crop material, and insufficient prior art flexible headers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

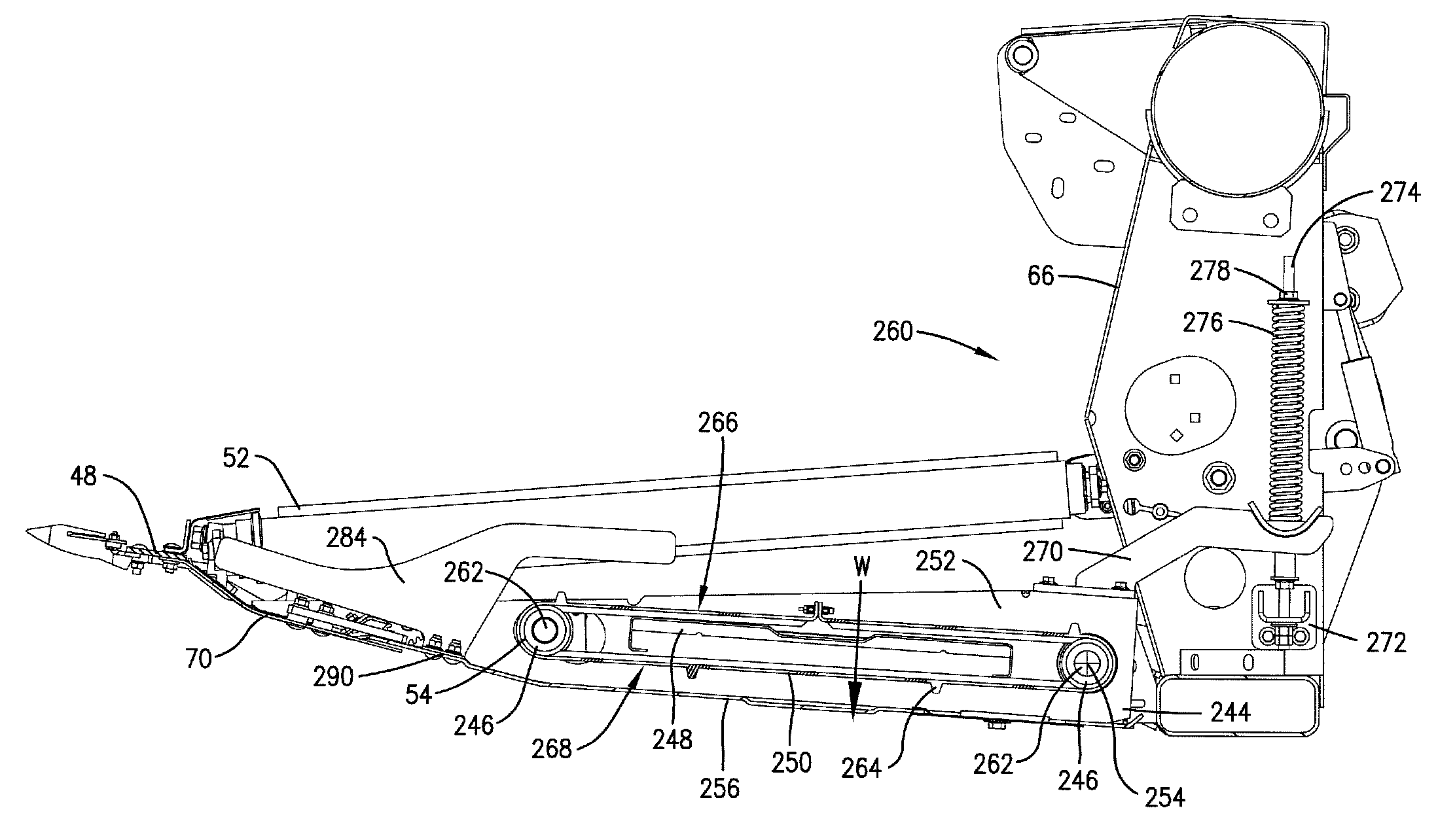

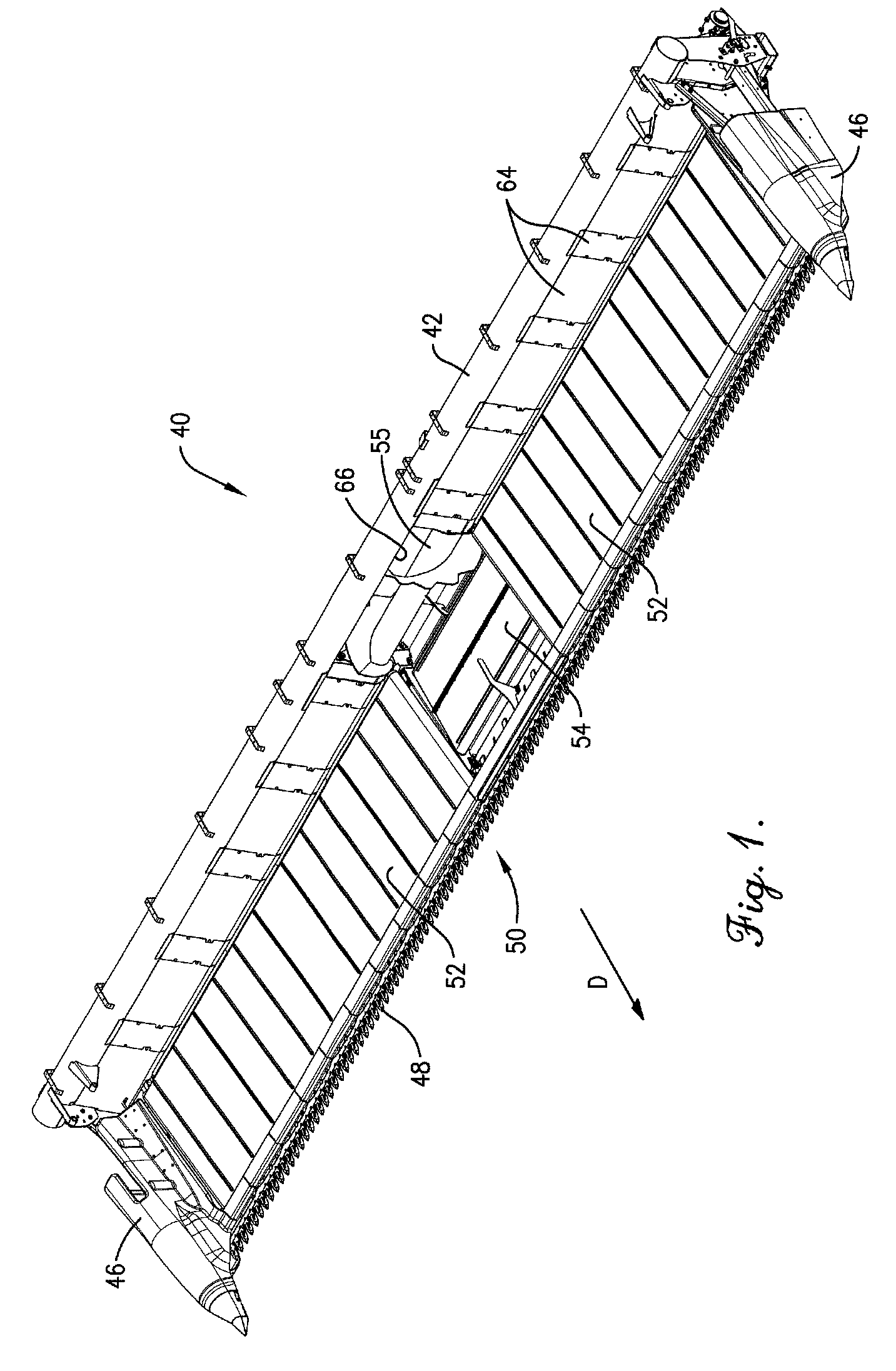

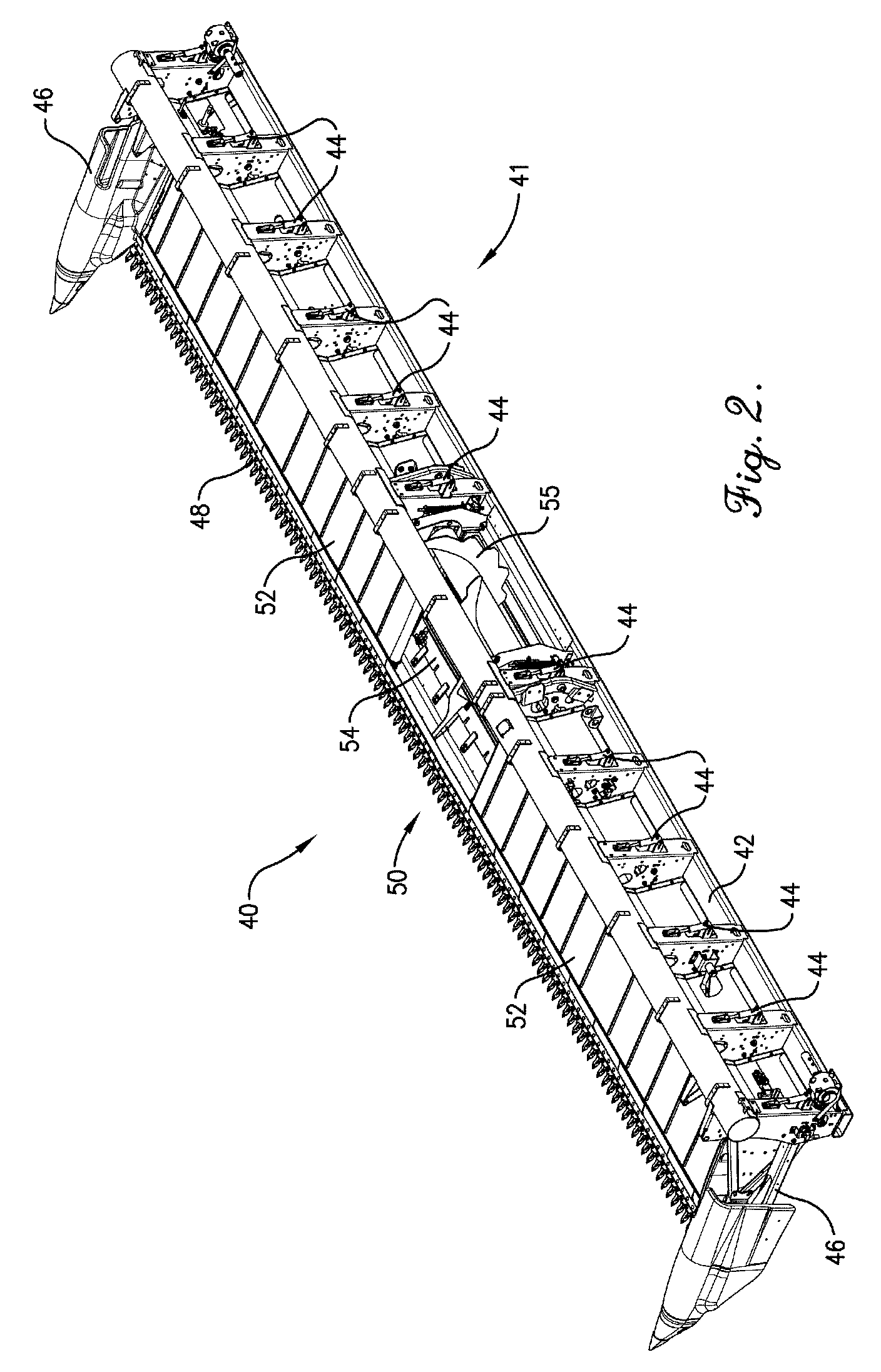

[0040]Turning initially to FIGS. 1 and 2, the harvesting header selected for illustration comprises a flexible header 40 and a header height sensing system 41. The harvesting header preferably forms part of a harvesting combine. The header 40 is configured for cutting and collecting a crop by being advanced in a generally forward direction D so that the crop can be fed to a feeder house (not shown) and further processed by other components (not shown) of the harvesting machine to produce grain. However, at least some aspects of the present invention could be used in other machines, such as a swather or mower.

[0041]The illustrated header 40 broadly includes a header frame 42, draper arm assemblies 44, end tilt arm assemblies 46, cutterbar assembly 48, and draper assembly 50, which includes side drapers 52 and center draper 54. The header 40 also includes a central collecting auger 55 spaced rearwardly of the center draper 54 and a reel (not shown) that extends the length of the heade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com