Forced air furnace

a forced air furnace and furnace technology, applied in the field of forced air furnaces, can solve the problems of inability to the length and complexity of the ductwork vary considerably, and the furnace cannot meet the ideal flow rate of a building, so as to overcome or mitigate one or more disadvantages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The forced air furnace of the present invention is provided with added adjustment mechanisms, allowing better tailoring of an airflow rate, airflow speed, air temperature and fan motor amperage. This added adjustability eventually translates to a better comfort for occupants of a building.

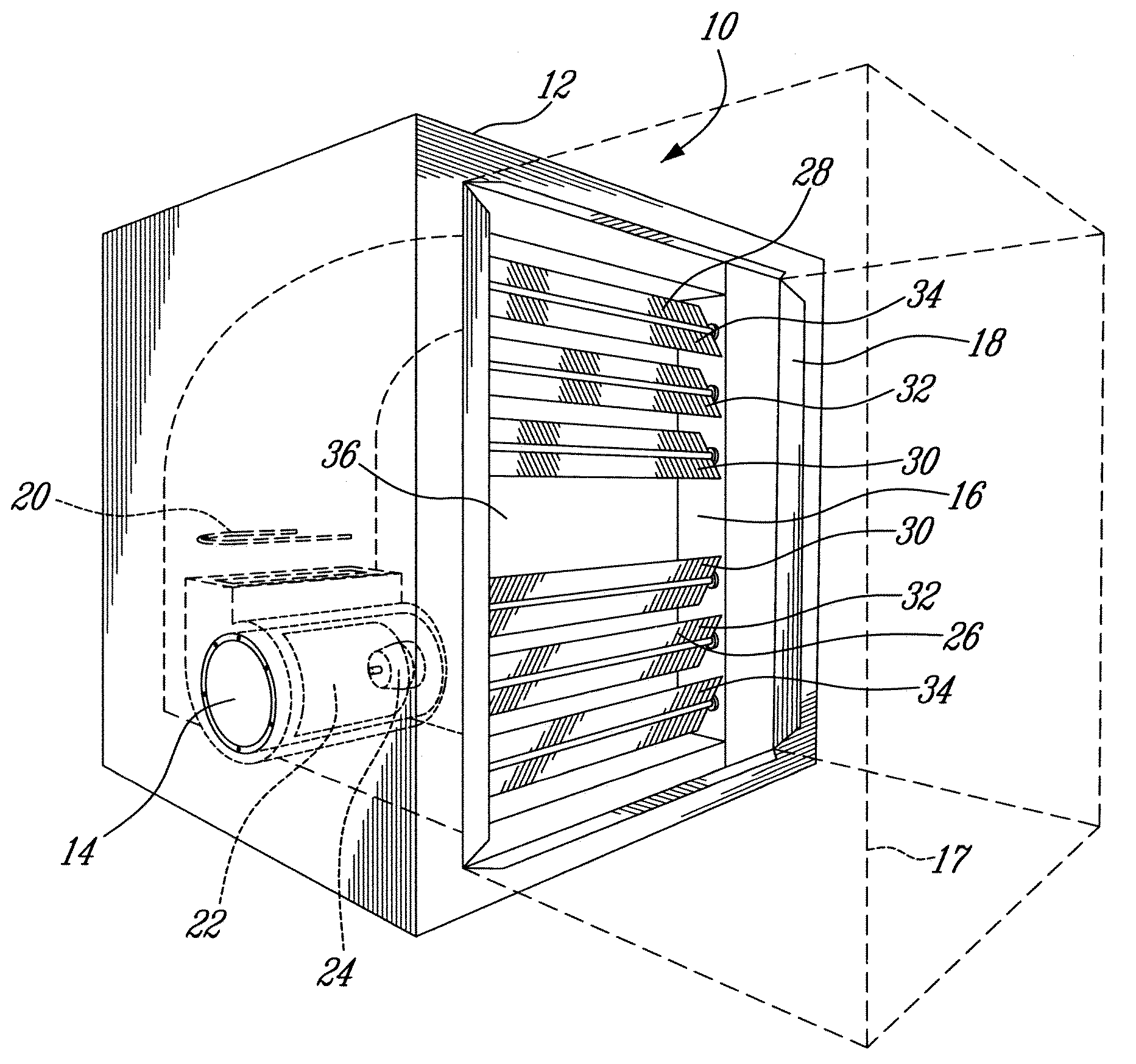

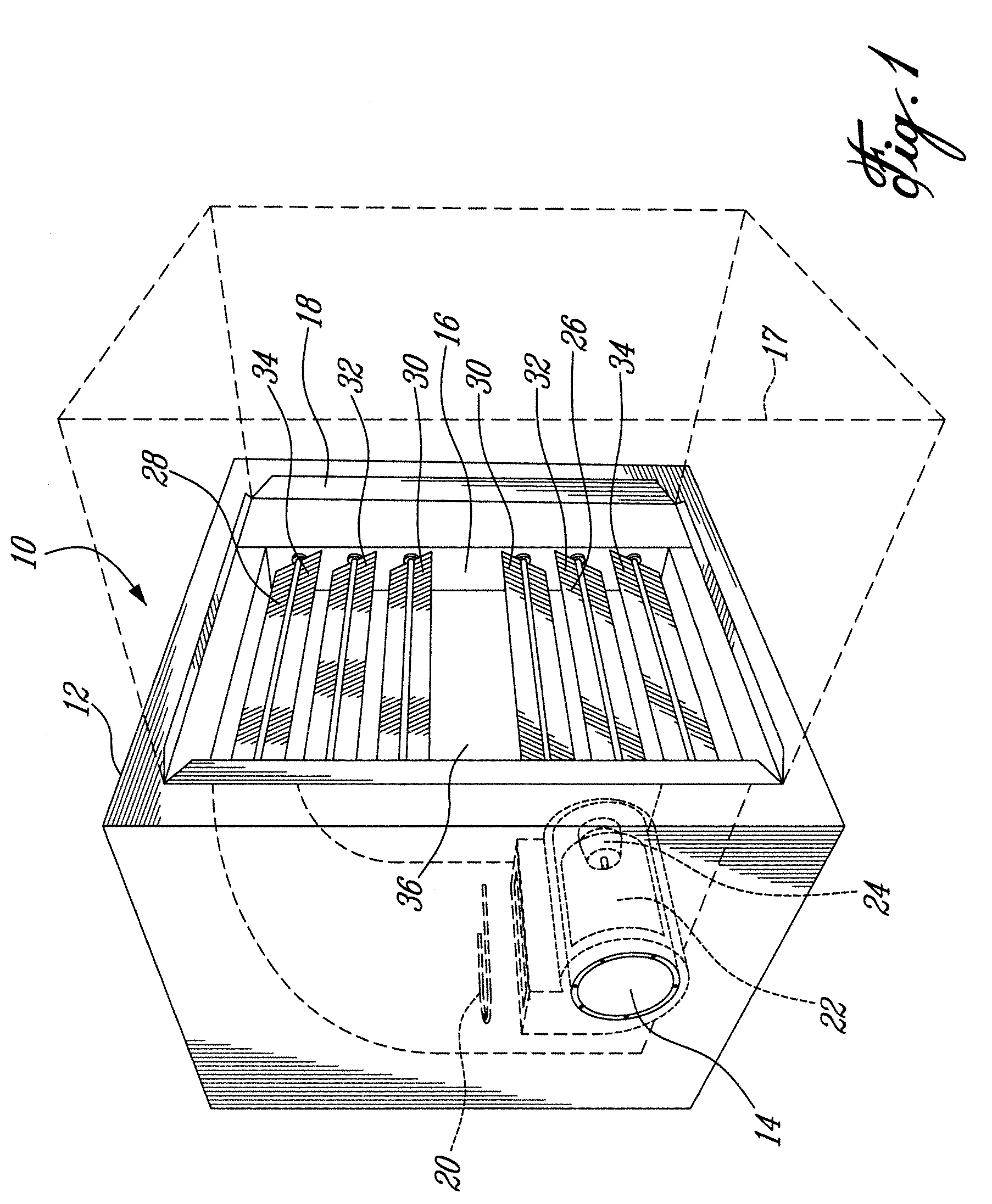

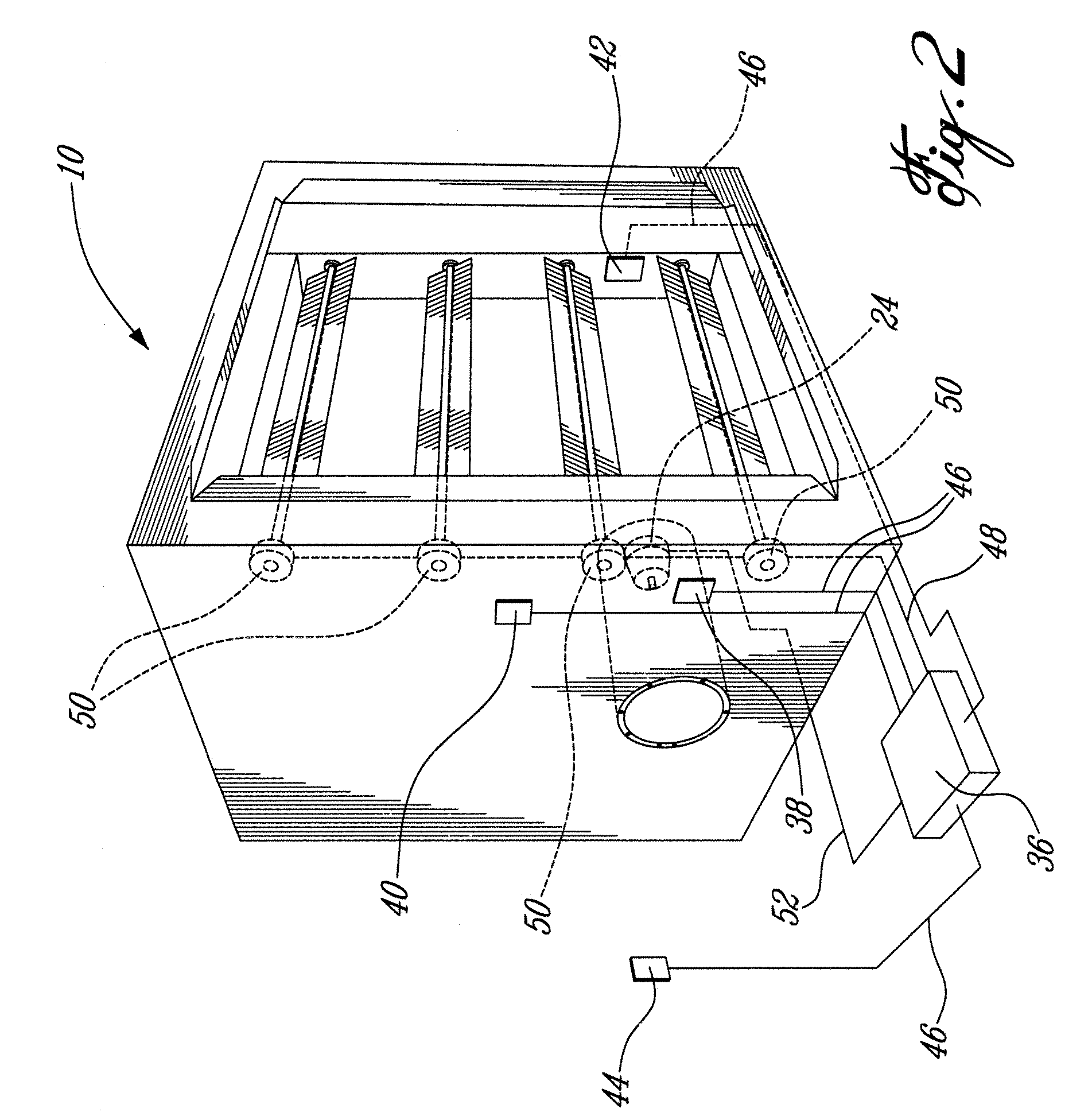

[0018]FIG. 1 generally depicts a forced air furnace 10. The forced air furnace 10 comprises an enclosure 12 in which an air inlet 14 and an air outlet 16 are provided. An interface 18 is also made in the enclosure 12, all around the air outlet 16. This interface 18 is used to connect the forced air furnace 10 to a duct 17, shown in dotted lines in this figure for clarity reasons. The enclosure 12 contains an electric heating element 20, such as a resisting element, and a fan 22 powered by its own electric fan motor 24. An outlet adjusting mechanism 26 is placed in the air outlet 16 to vary the effective size, or exhaust area, of the air outlet 16. This way, the outlet adjusting mechanism 26 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com