Linear Table with an Adjustable Dust-proof Structure

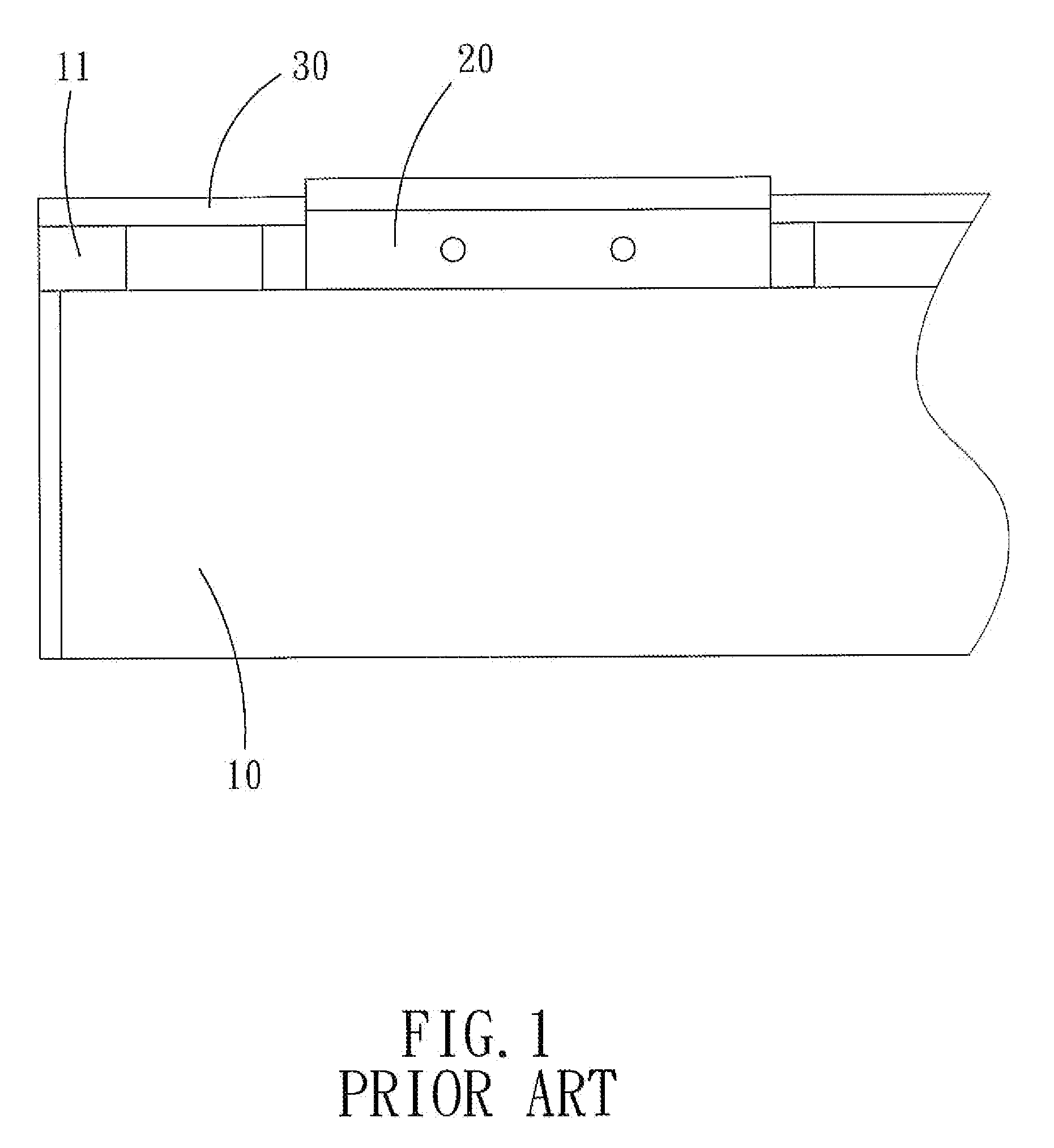

a technology of dust-proof structure and linear table, which is applied in the direction of linear bearings, shafts and bearings, bearings, etc., can solve the problems of linear table damage, large weight of single dust-proof structure b>30/b>, space waste, and design difficulty, so as to reduce the weight of dust-proof structure, and increase the torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The present invention will be more clear from the following description when viewed together with the accompanying drawings, which show, for purpose of illustrations only, the preferred embodiment in accordance with the present invention.

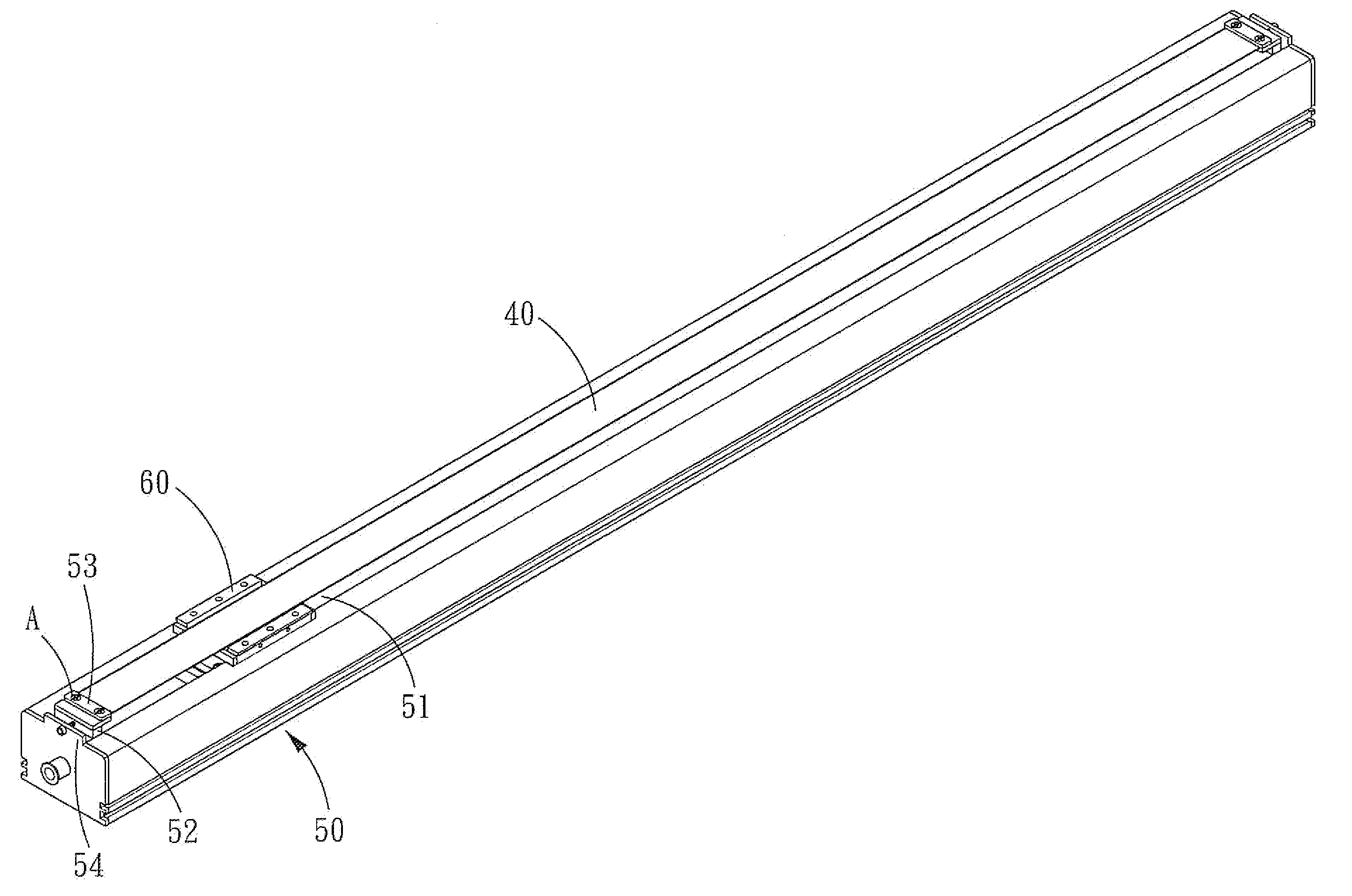

[0020]Referring to FIG. 5, a linear table with an adjustable dust-proof structure in accordance with a preferred embodiment of the present invention comprises a stator 50 and a runner 60. The stator 50 includes a linear guideway 51, and each end of the guideway 51 is formed with a positioning piece 54. Each of the two positioning pieces 54 is locked with a loading rack 52 by a screw B. The locking direction of the two loading racks 52 corresponds to the direction of the guideway 51. The runner 60 can be slidably disposed in the guideway 51 of the stator 50, so as to enable the runner 60 to linearly move along the guideway 51 of the stator 50. Both ends of an elongated sheet-like dust-proof structure 40 are positioned on the two loading racks 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com