Vitrified bond grinding wheel and process for producing the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

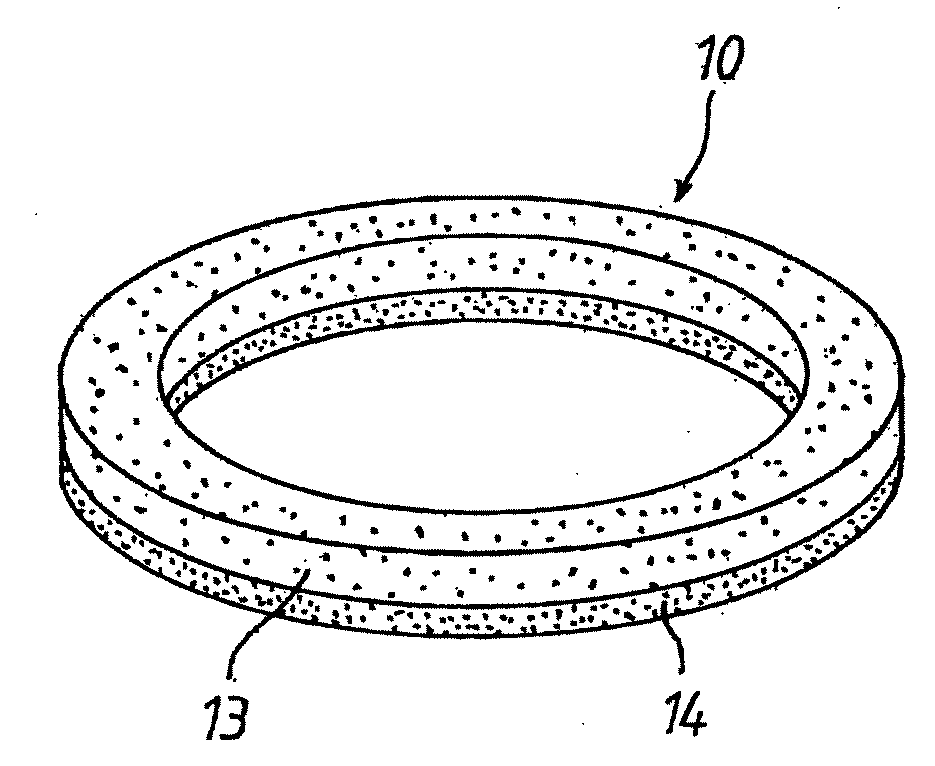

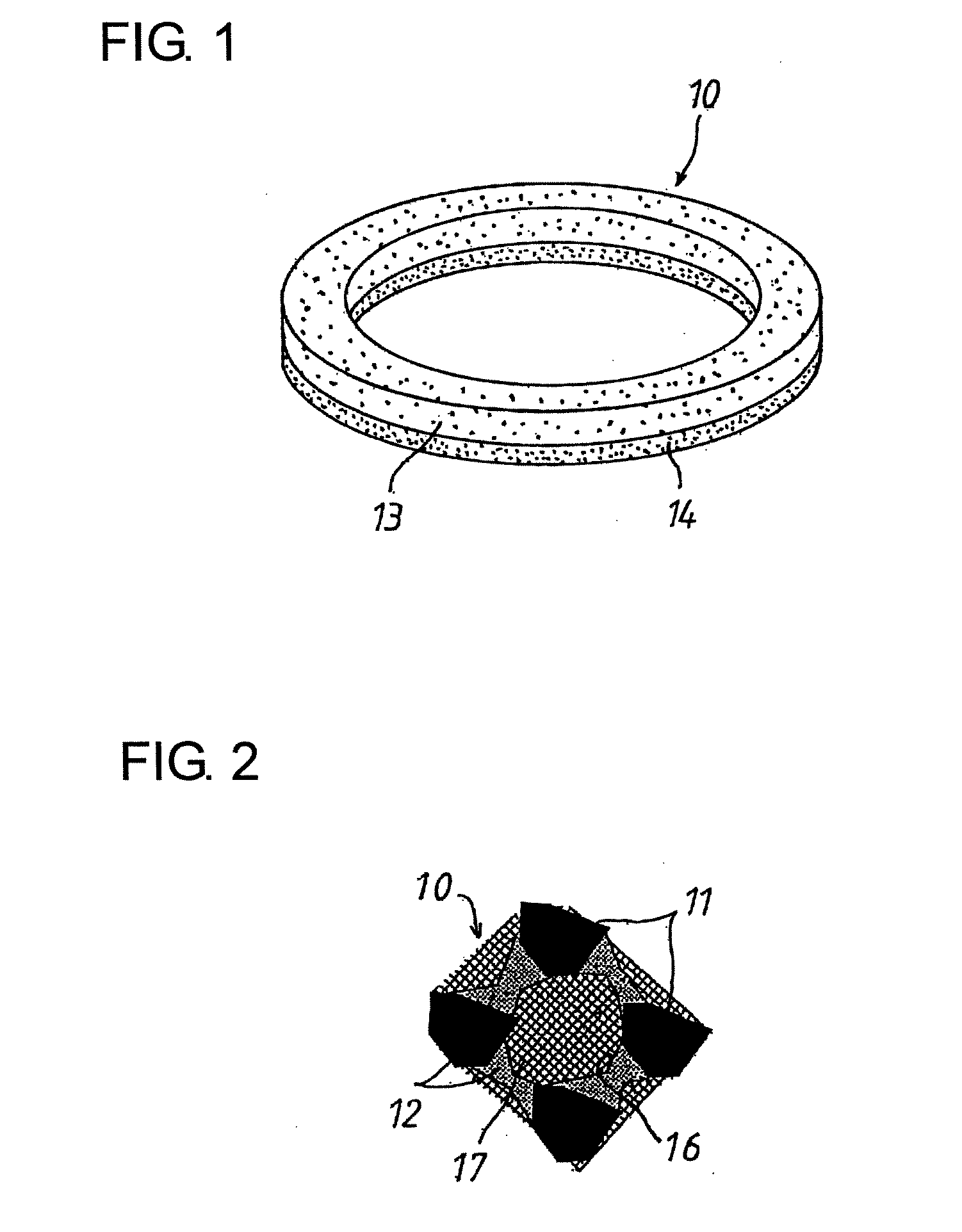

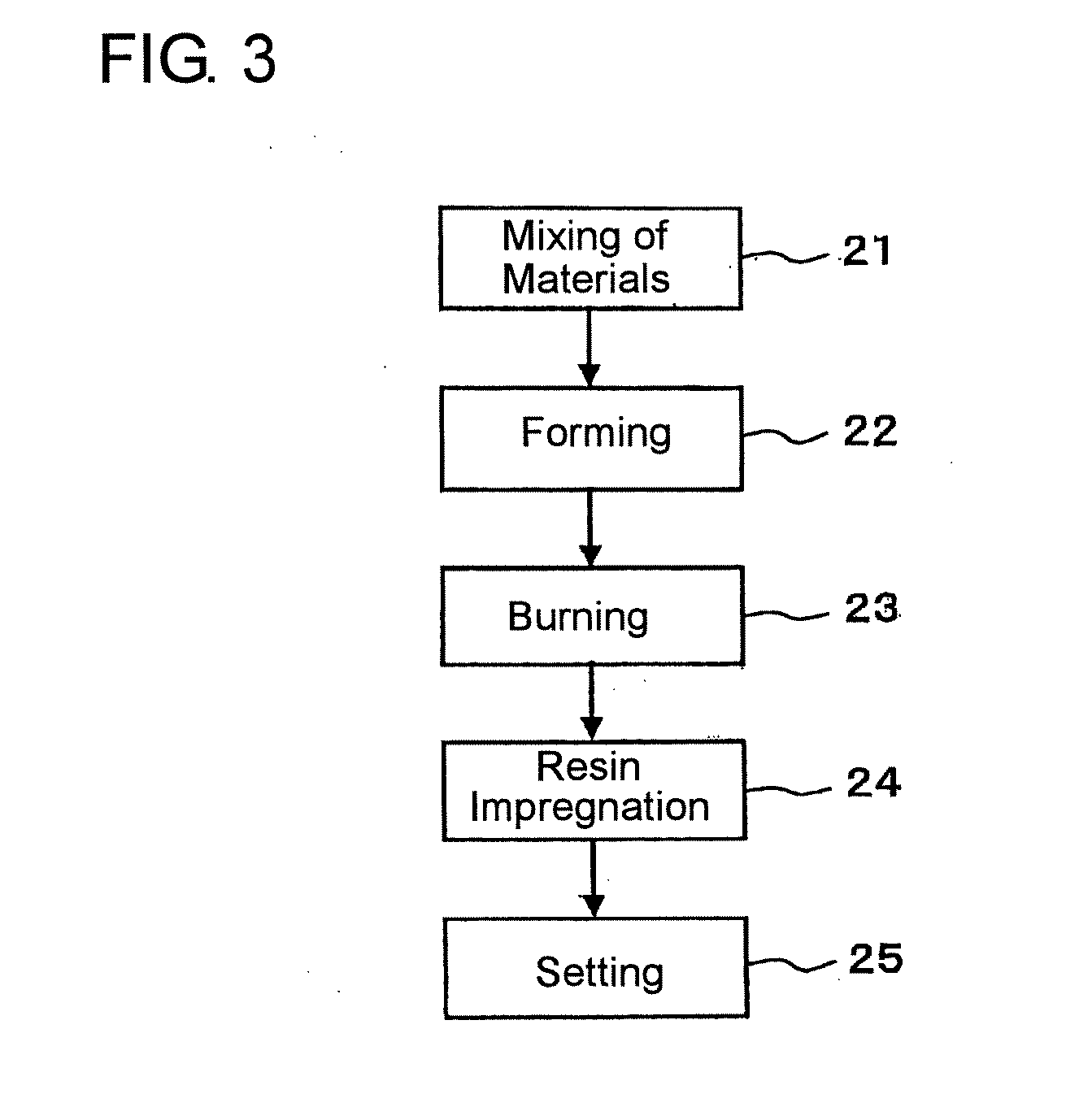

[0024]Hereafter, embodiments according to the present invention will be described with reference to the drawings. Referring to FIGS. 1 and 2, numeral 10 denotes a ring-like grinding wheel substance having superabrasive grains 11 such as CBN, diamond or the like bonded with a vitrified bond 12. The grinding wheel substance 10 takes a two-layer structure in which an abrasive grain layer 13 having the superabrasive grains 11 bonded with the vitrified bond 12 and a foundation layer 14 not including such superabrasive grains are piled up and bonded bodily. The abrasive grain layer 13 is of the structure that the superabrasive grains 11 are bonded with the vitrified bond 12 to the depth of, e.g., 3 to 5 mm, wherein particles such as aluminum oxide (Al2O3) are mixed as aggregate in the vitrified bond 12 if necessary. Further, the foundation layer 14 is of the structure that foundation particles such as ceramics particles or the like are bonded with the vitrified bond to the depth of, e.g.,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Thermosetting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com