Wall System Having Furniture Modules and Accessories for Attaching and Finishing the Modules

a wall system and furniture technology, applied in the field of ready-to-assemble furniture, can solve the problems of difficult disassembly and assembly of rta furniture modules to provide a furniture system, and achieve the effect of improving the quality of the finished product and reducing the difficulty of disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

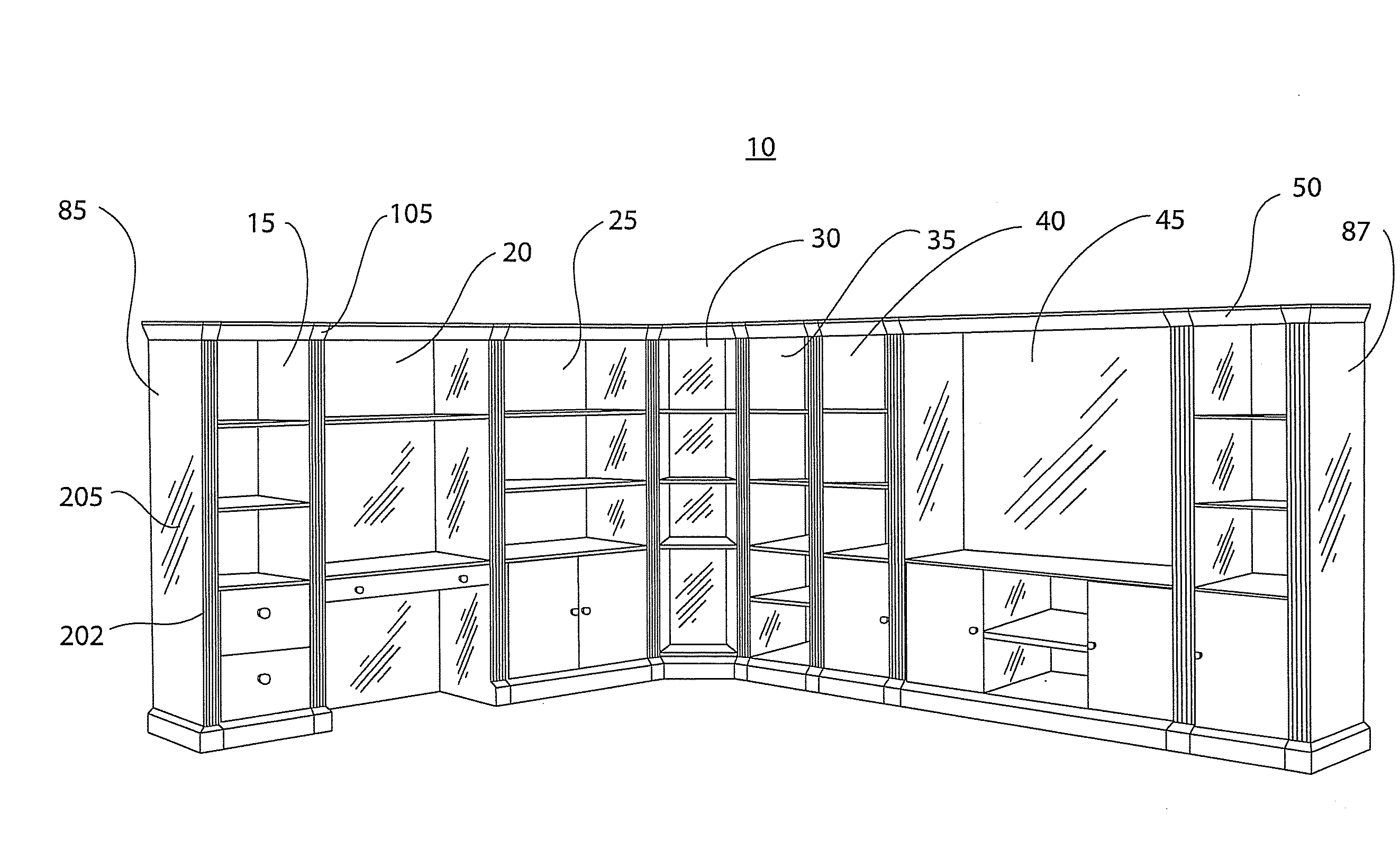

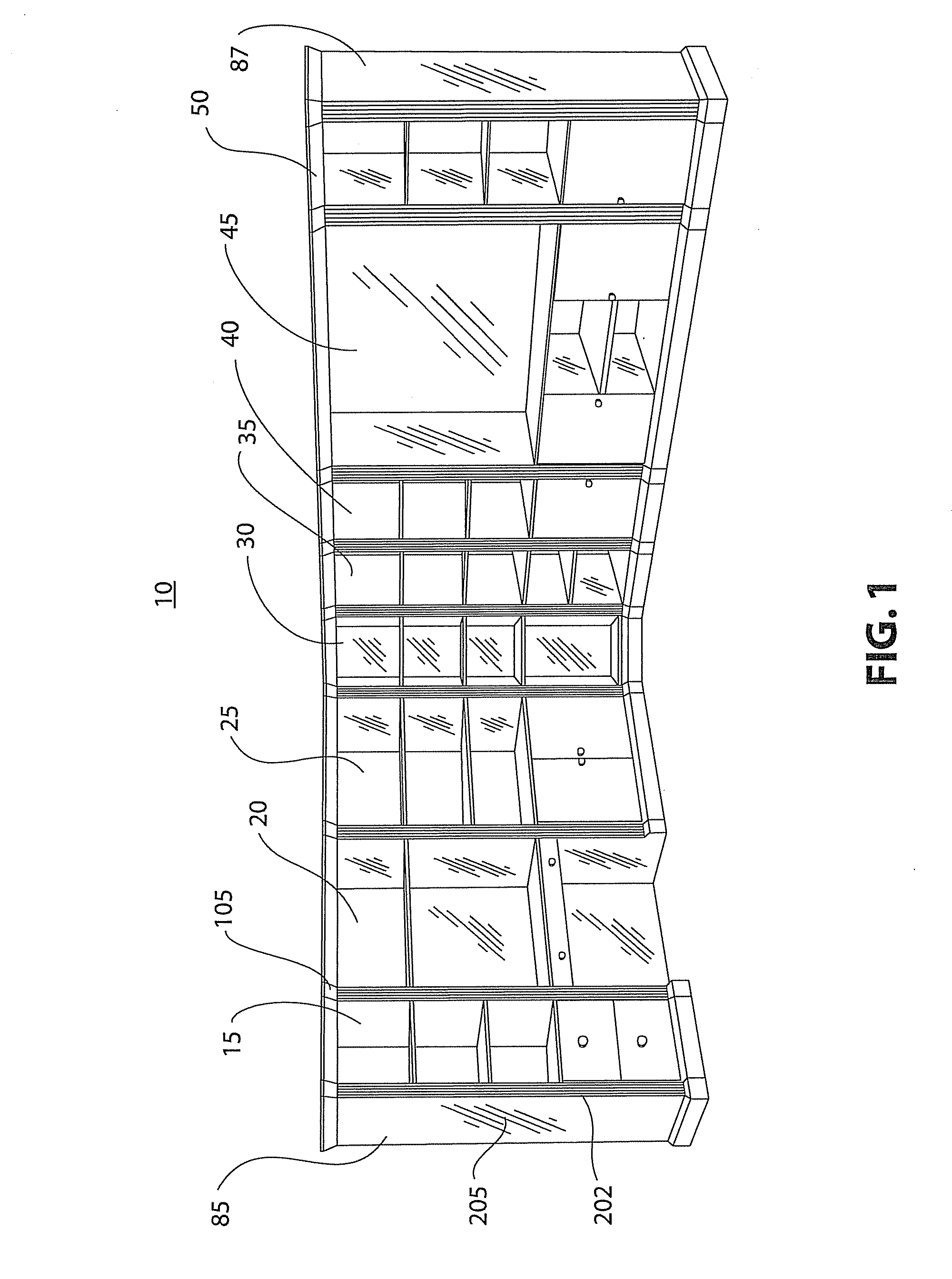

[0034]FIG. 1 illustrates a furniture system 10 comprised of a plurality of interconnected furniture modules. In particular, from left to right in the sequence of their attachment are a standard module 15, an office module 20, a library module 25, a corner module 30, a standard module 35, another standard module 40, an entertainment module 45 and finally, a standard module 50. As will be seen, each of these modules is separate and distinct from one another and is connected together using fasteners, pilasters and end caps that will be hereinafter described in detail. Standard module 15 and standard module 50, since they are at the ends of the system 10, are end modules while the remaining modules in the system 10 are interior modules.

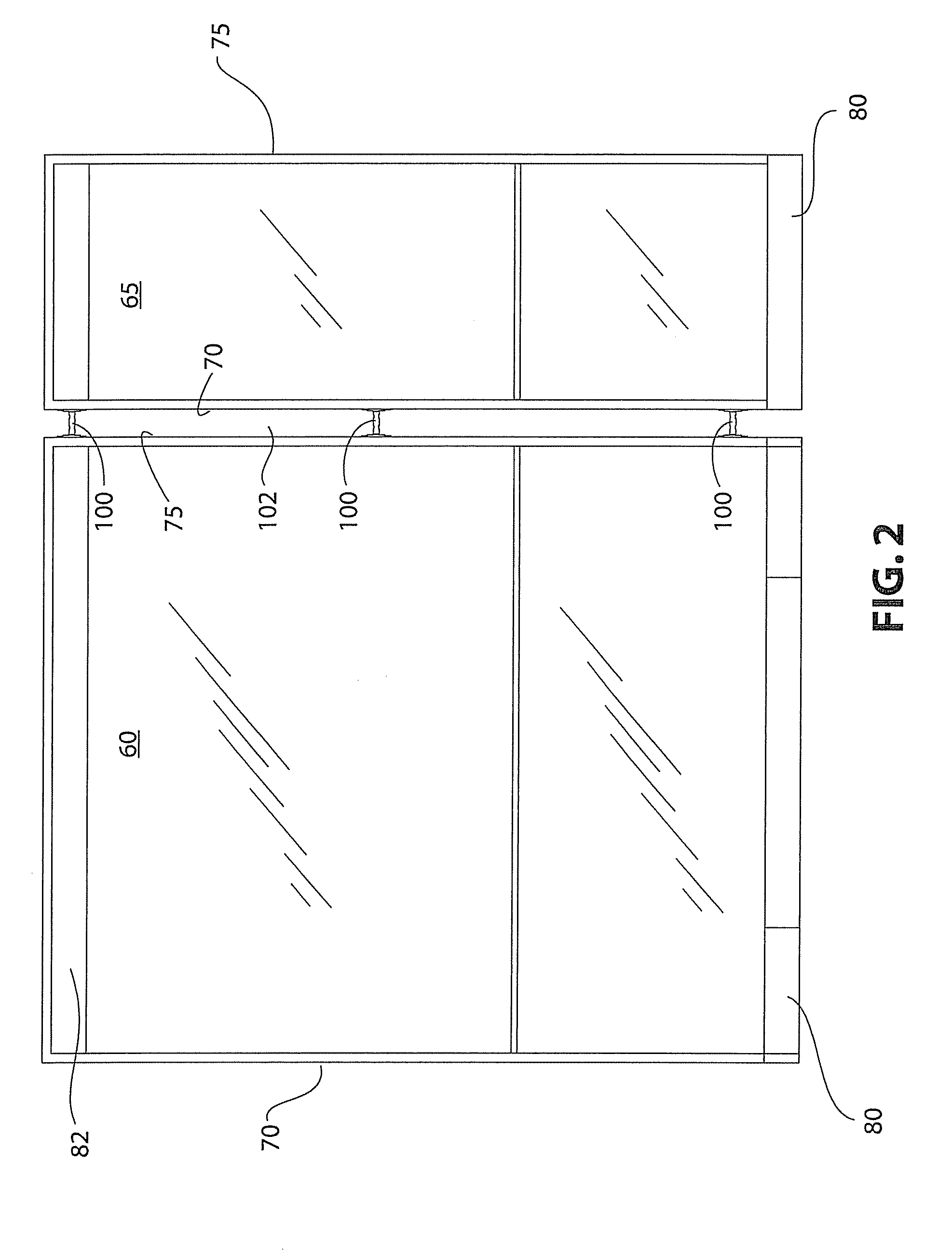

[0035]FIGS. 2 and 3 illustrate a pair of modules which, for purposes of this specification, will be referred to as a first module 60 and a second module 65. The purpose of such a generic label is to make clear that the first module 60 and second module 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Color | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com