Litho-mosaic

a technology of mosaics and concrete, applied in the field of litho-mosaic products, can solve the problems of high labor and cost, often very beautiful and detailed mosaics, and the construction of mosaics in walls and other decorative structures may be quite laborious and expensive, and achieve the effect of enhancing the massaging of tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

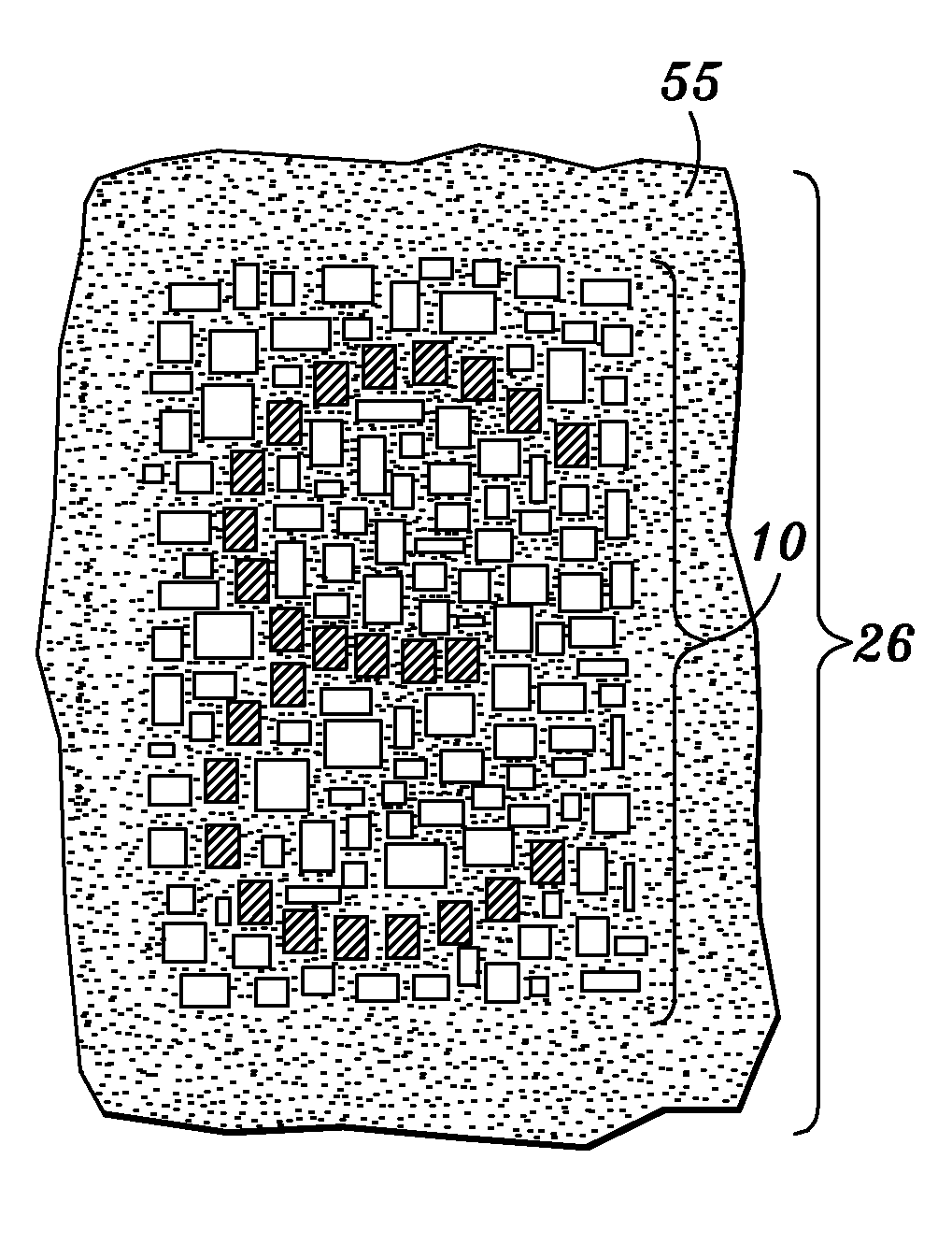

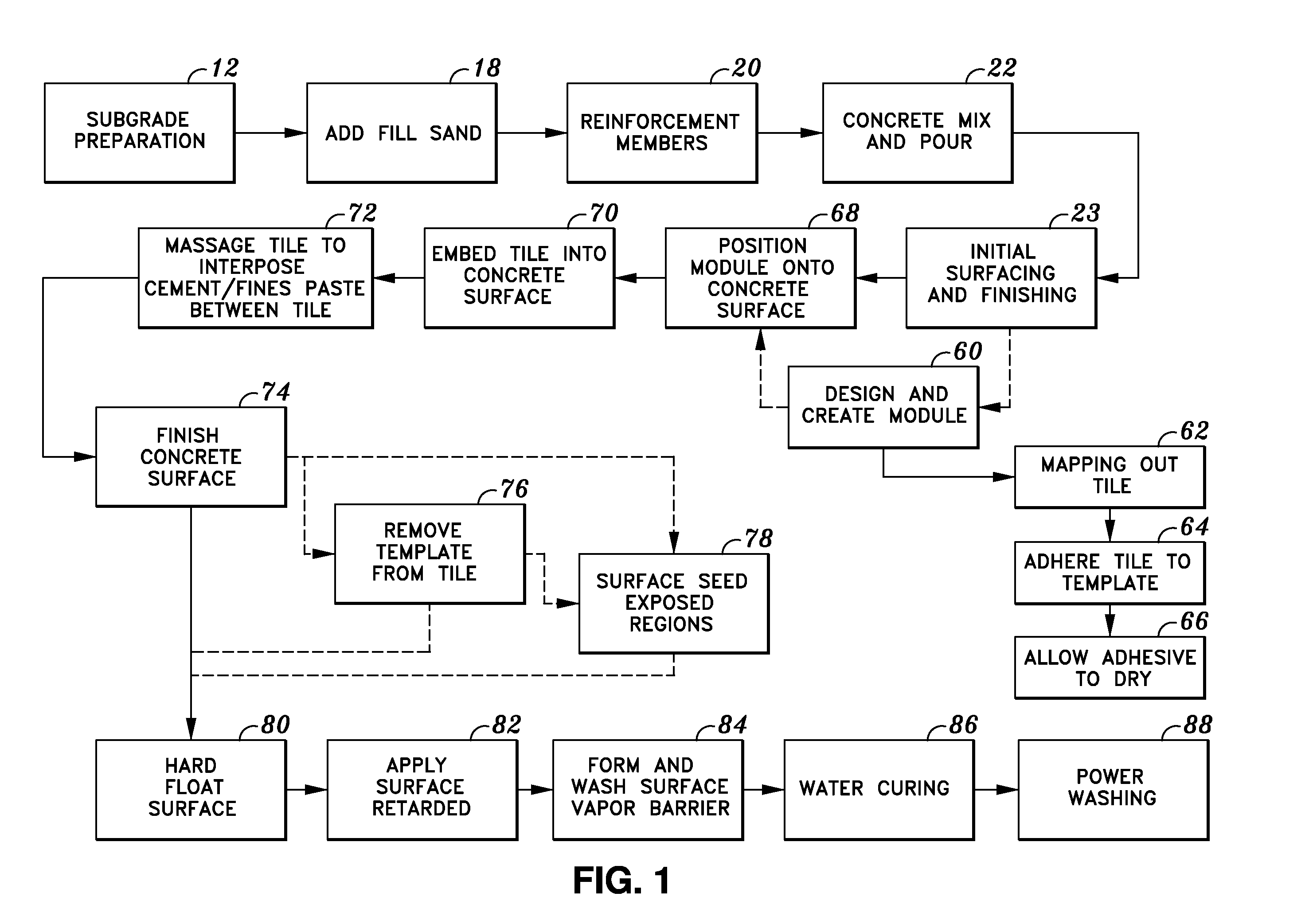

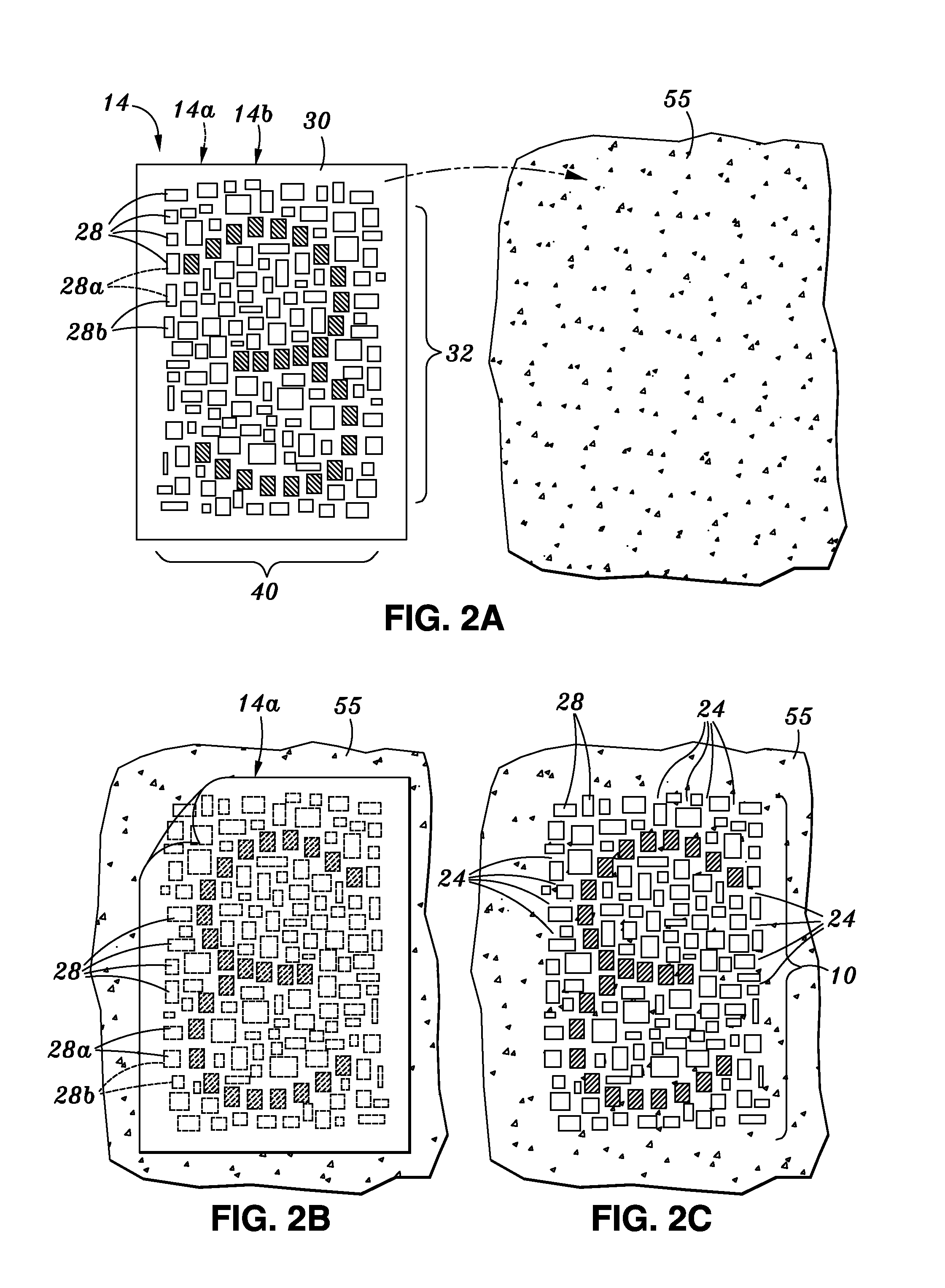

[0026]Referring now to the drawings wherein the showings are for purposes of illustrating a preferred embodiment of the invention only, and not for purposes of limiting the same, FIG. 1 is a block diagram illustrating a method of designing, creating and installing a mosaic 10, as shown in FIG. 4. The teachings herein may be utilized in flooring applications, artistic figures and works, and vertical applications, including walls, in order to facilitate the creation of the mosaic 10. For example, it is contemplated that the methods disclosed herein may be utilized to create the mosaic upon objects such as statues, seating, sculpture, bowls, walls, and flooring applications such as pavers and within molds for walls and foundations, and the like. According to the method illustrated in FIG. 1, the mosaic 10 may be installed upon an uncured concrete surface utilizing a module 14, as shown in FIGS. 2A-2C and 3A-3C. As will be understood by one of skill in the art, the present methods and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com