Packaging member

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

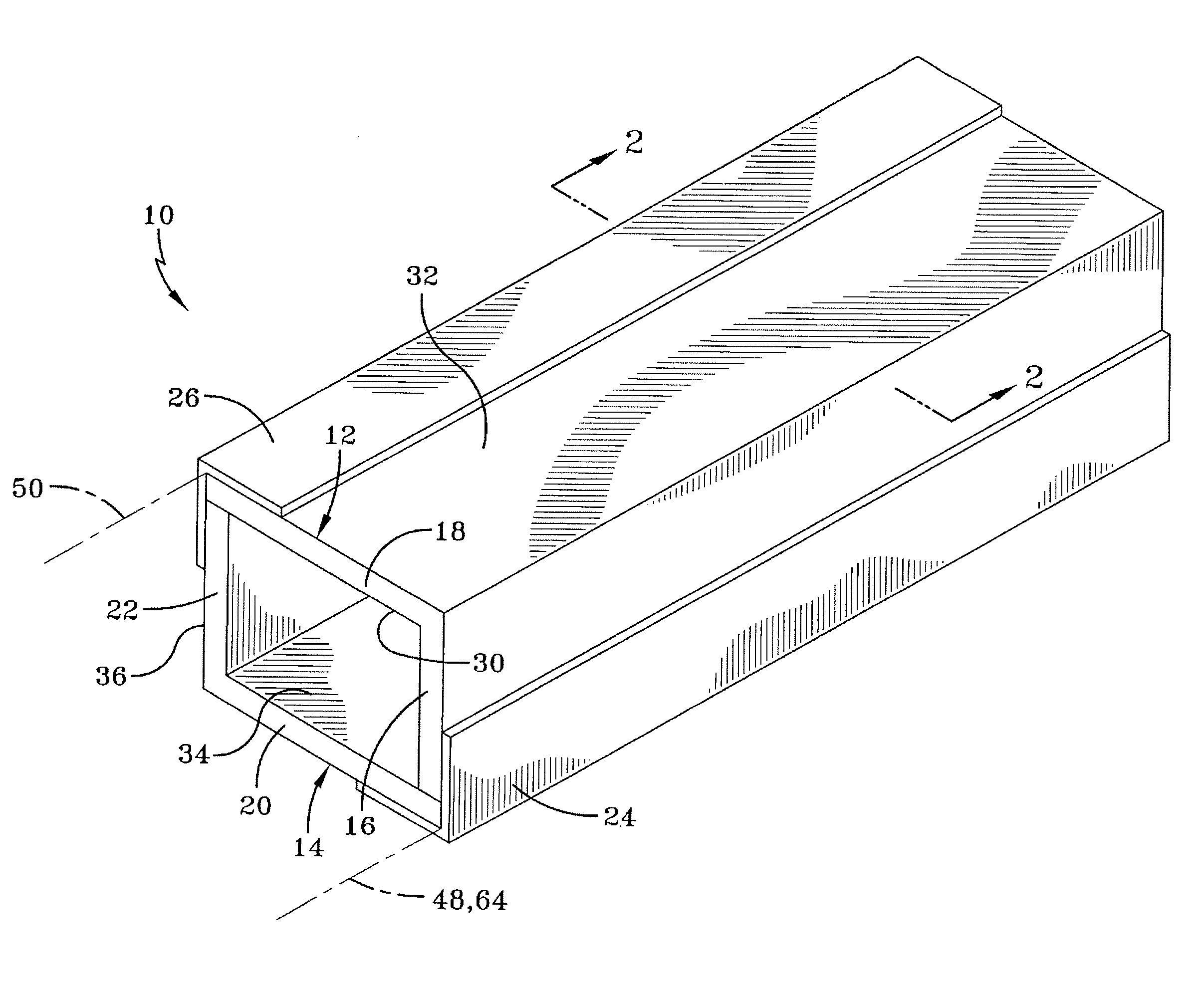

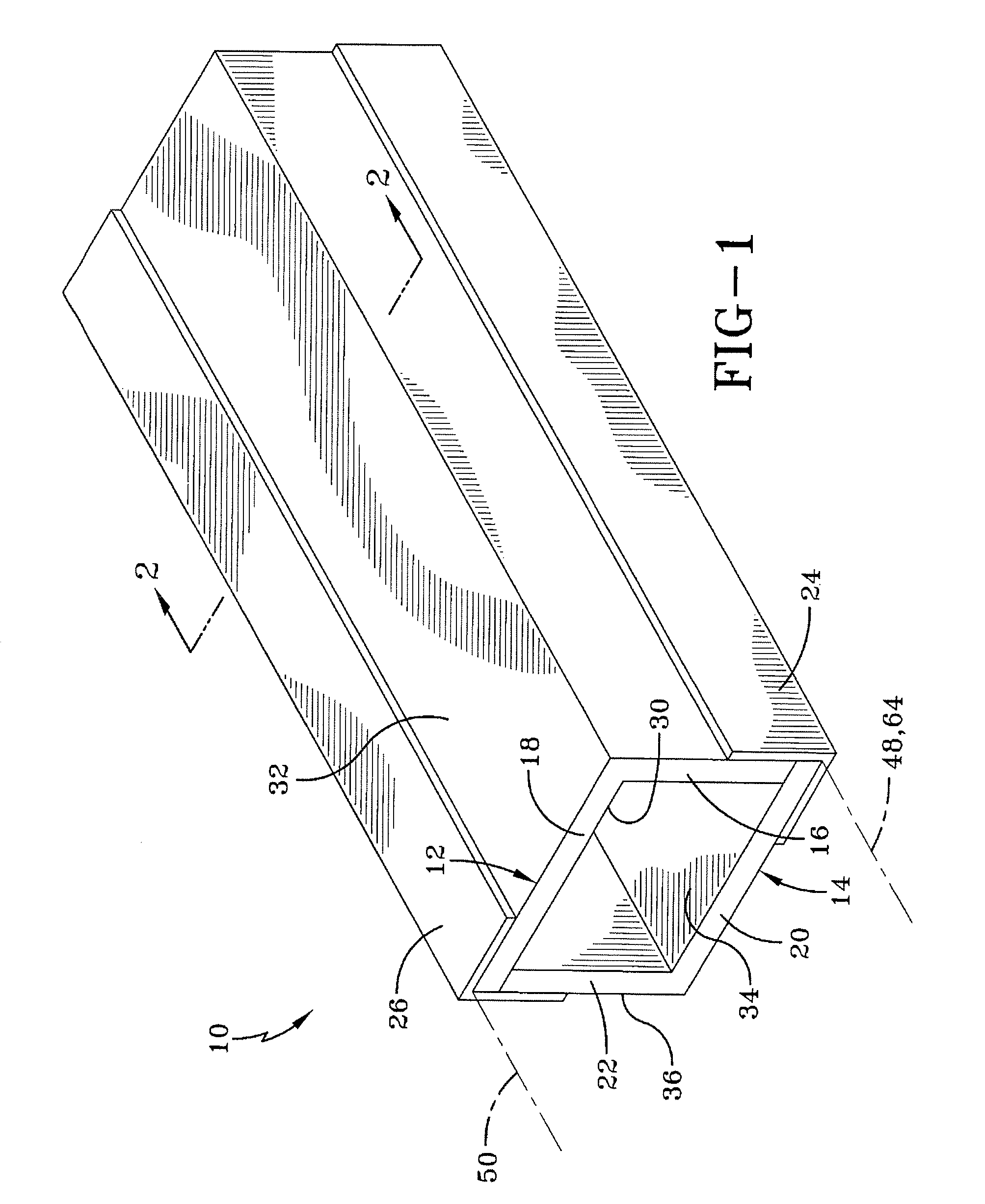

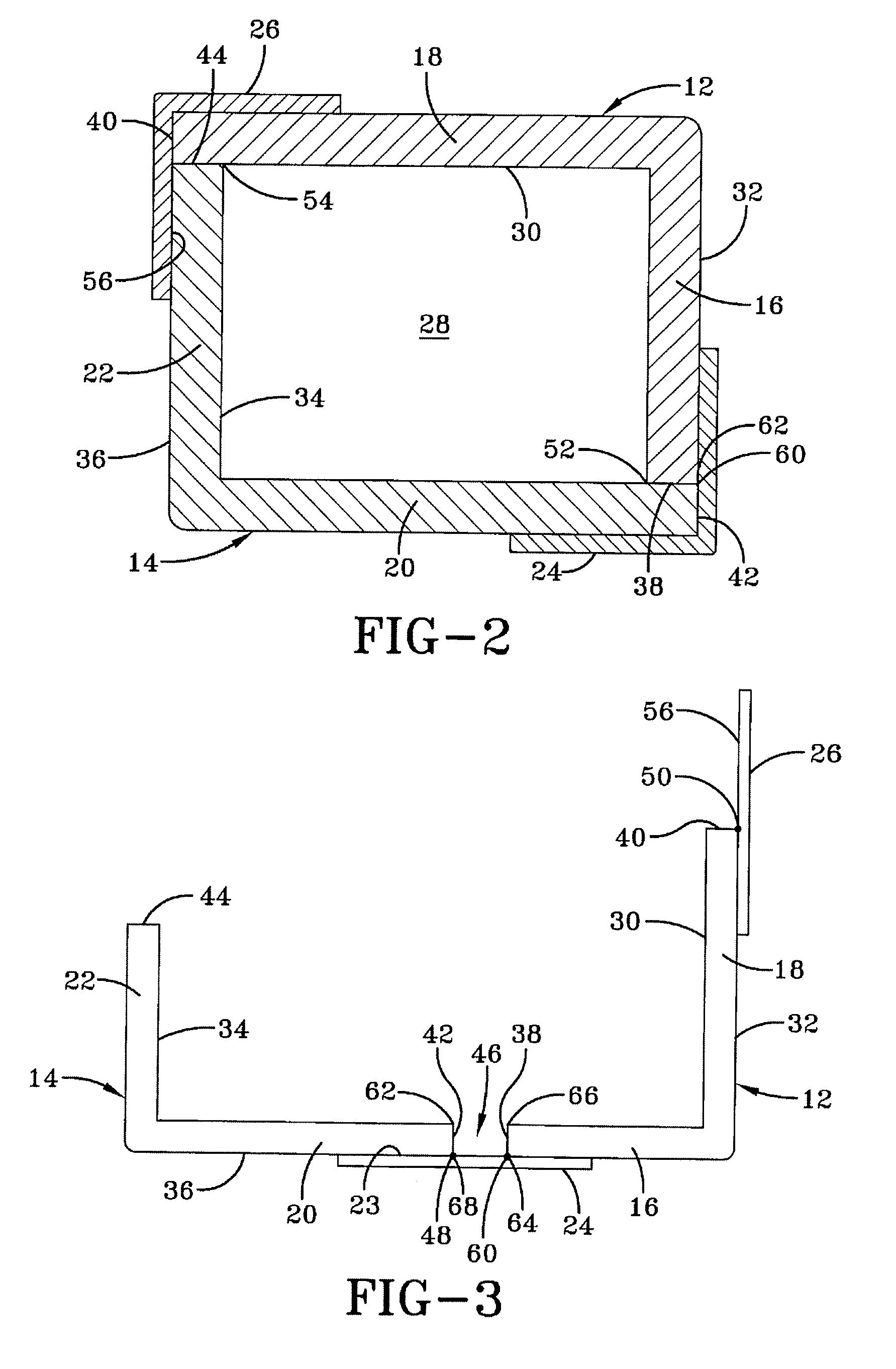

[0037]FIG. 1 illustrates a packaging member 10 for protecting an article (not shown) that is placed inside packaging member 10 prior to transporting the article. Packaging member 10 includes an opposed pair of rigid members 12, 14, commonly referred to as corner posts, angles or L-shaped members. Angles or L-shaped members 12, 14 each have a pair of respective legs 16, 18 and 20, 22. It is to be understood that the legs of L-shaped members can be of identical widths or different widths. Each pair of legs 16, 18 and 20, 22 are substantially perpendicular to one another, are of rigid construction with one another and have an L-shaped cross section along their length. The legs 16, 18 and 20, 22 collectively define the structural sides of packaging member 10 when assembled. Referring to FIGS. 1-3, angle 12 has an inner surface 30, outer surface 32 and legs 16, 18. Angle 14 has an inner surface 34, outer surface 36 and legs 20, 22. In one embodiment, an external member applied to an oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com