Electrical device and plug for an electrical device

a technology of electrical devices and plugs, which is applied in the direction of connection contact materials, coupling device connections, piston pumps, etc., can solve the problems of electrical contact interruption, failure of pumping devices, corrosion of electrical connections, etc., and achieves high current consumption, simple sealing of separate chambers, and economic effect of sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

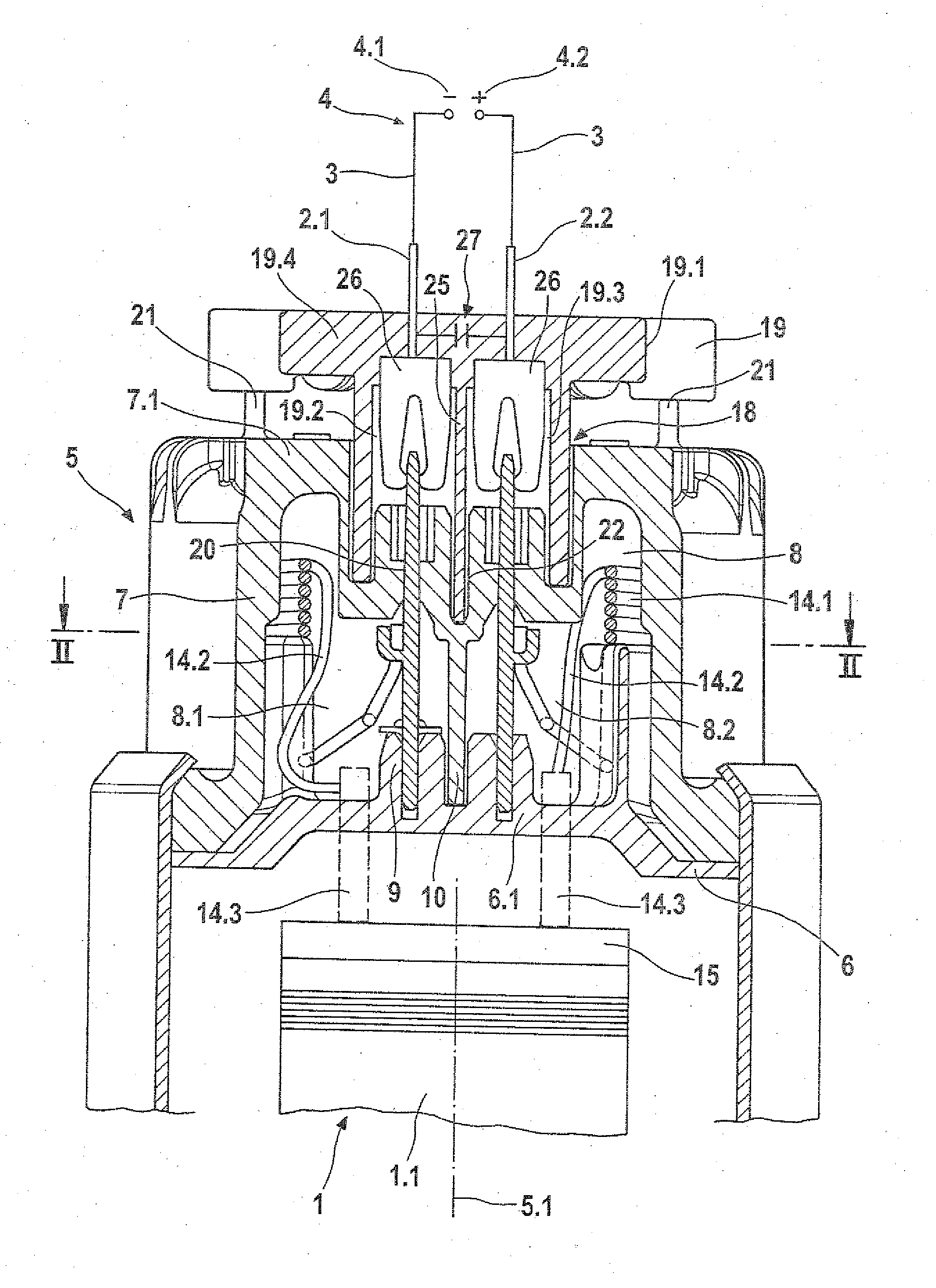

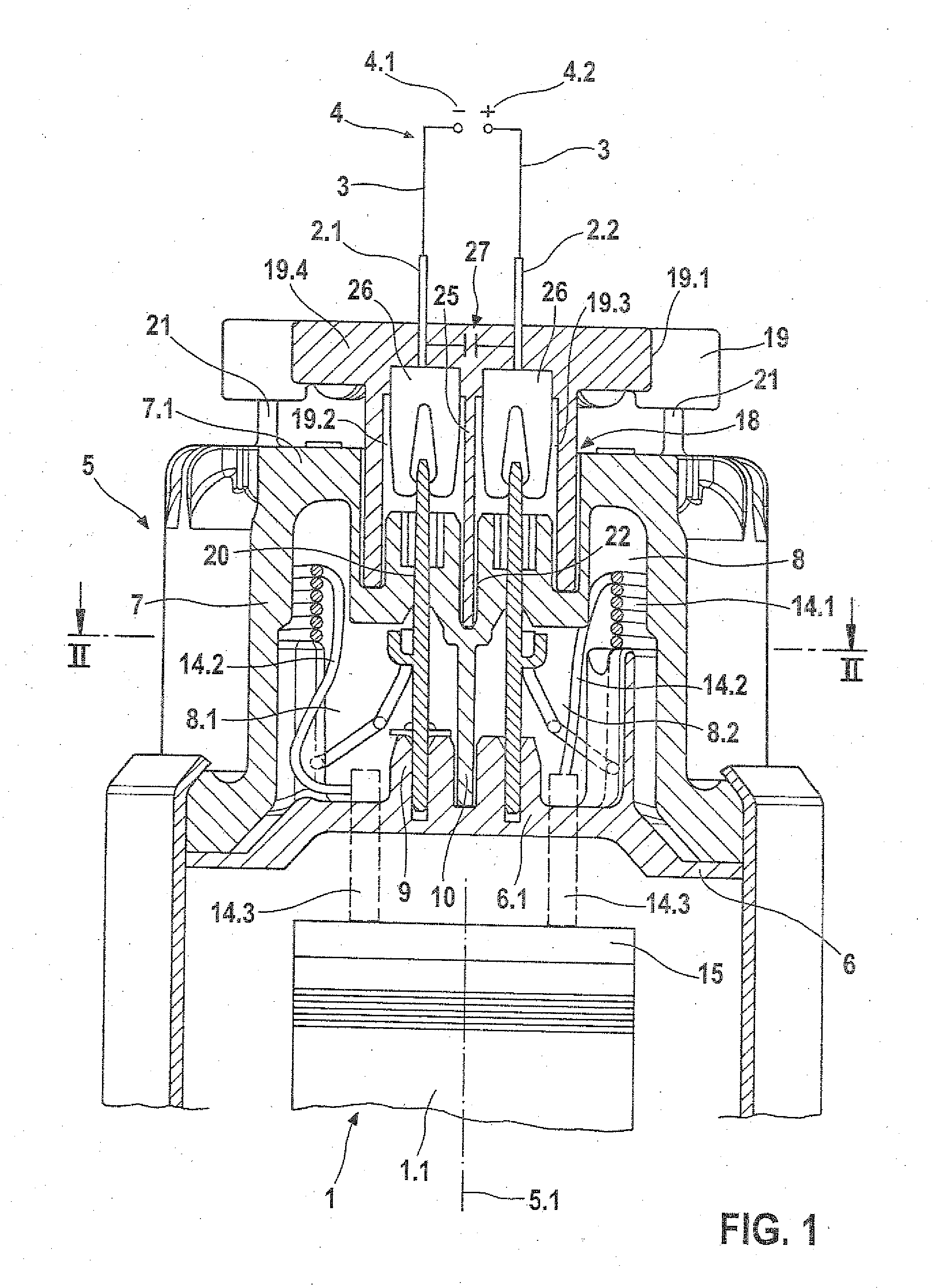

[0022]FIG. 1 shows an electrical device according to the invention in section, taking a pumping device as an example.

[0023]The electrical device according to the invention has an electrical consumer 1, such as an electric motor 1.1, which is connected to a voltage source 4 via electrical connections 2 and electrical connection cables 3 adjoining them. In the exemplary embodiment, two electrical connections 2.1, 2.2 are provided, of which one is connected to a negative pole 4.1 and the other to a positive pole 4.2 of the voltage source 4. As an example, the electrical connections 2 are embodied in the form of plug tugs, pins, or prongs and are intended for contacting to a connection plug.

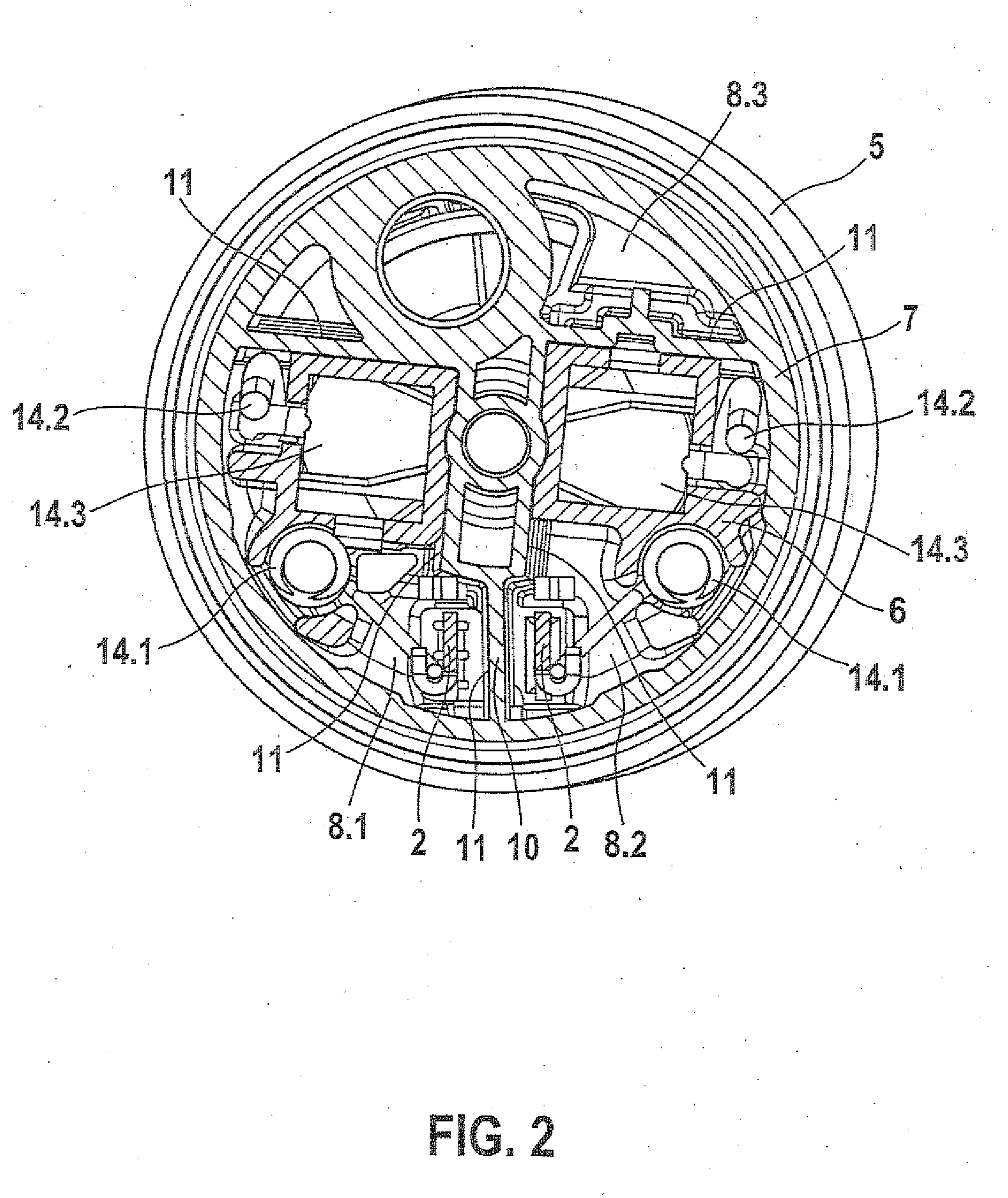

[0024]The electrical device has a housing 5 with a connection lid 6 and a connection cap 7 slipped over the connection lid 6. Between the connection lid 6 and the connection cap 7, a hollow chamber 8 is formed. The electrical connections 2 extend through the connection cap 7 into the hollow chamber 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com