Duplex Elastomer Component Used As A Bowstring Shock Suppressor

a technology of shock suppressor and elastomer, which is applied in the direction of bow/crossbow, white arms/cold weapons, bows/crossbows, etc., can solve the problems of immediate cease of bowstring vibration and attendant noise, and achieve the effect of suppressing vibration and noise in the bow, reducing the frequency of ejection, and eliminating bowstring oscillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

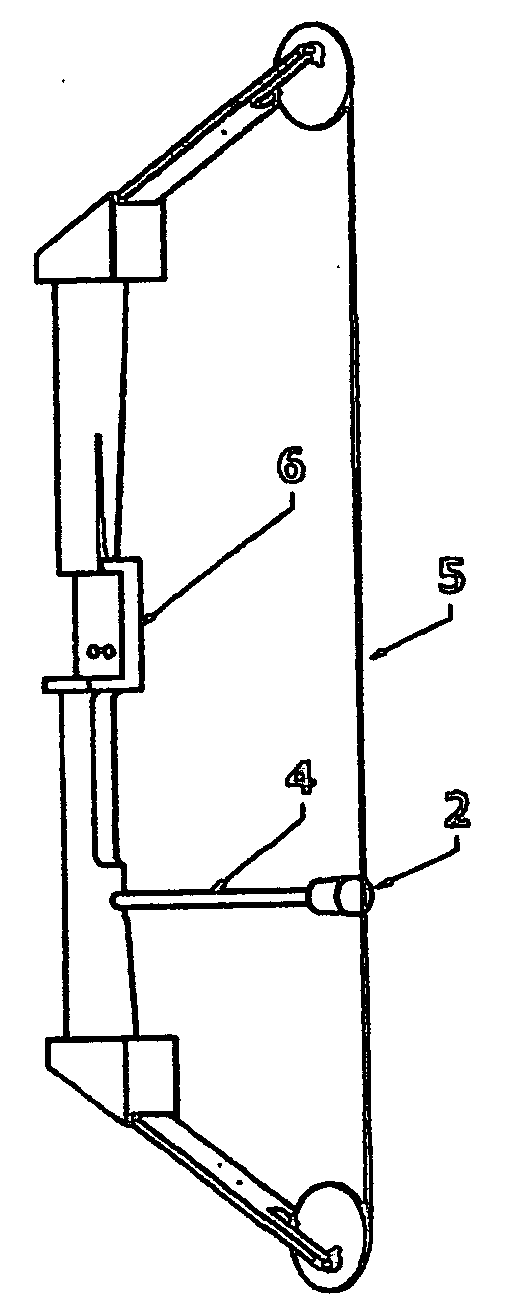

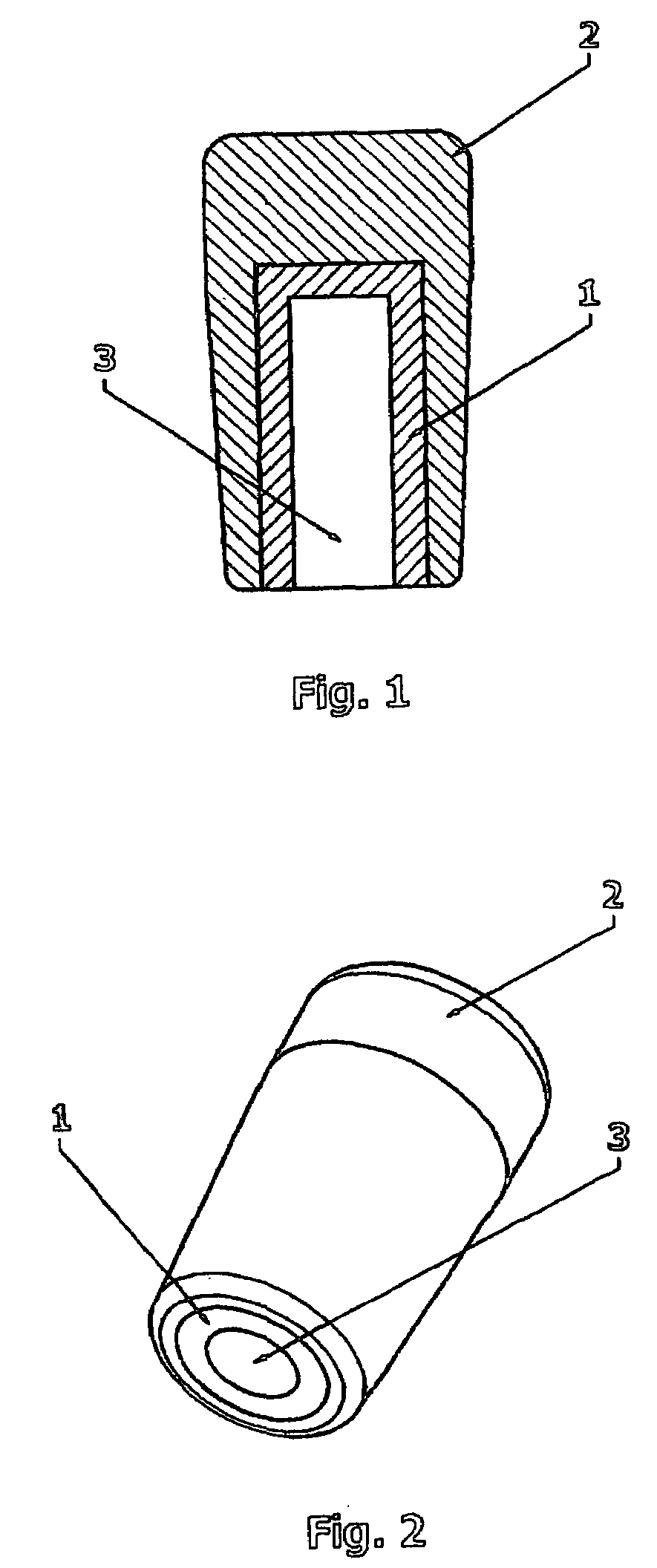

[0039]FIG. 1 shows a device to suppress bowstring vibrations. The inner hard rubber insert 1 with a hole 3 for installing on a mounting rod and gel overmolded shell 2.

[0040]FIG. 2 shows a device used to suppress bowstring vibrations. The mounting hole 3 is sized to fit tightly over mounting rod by hard rubber insert 1 which supports the gel overmolded shell 2.

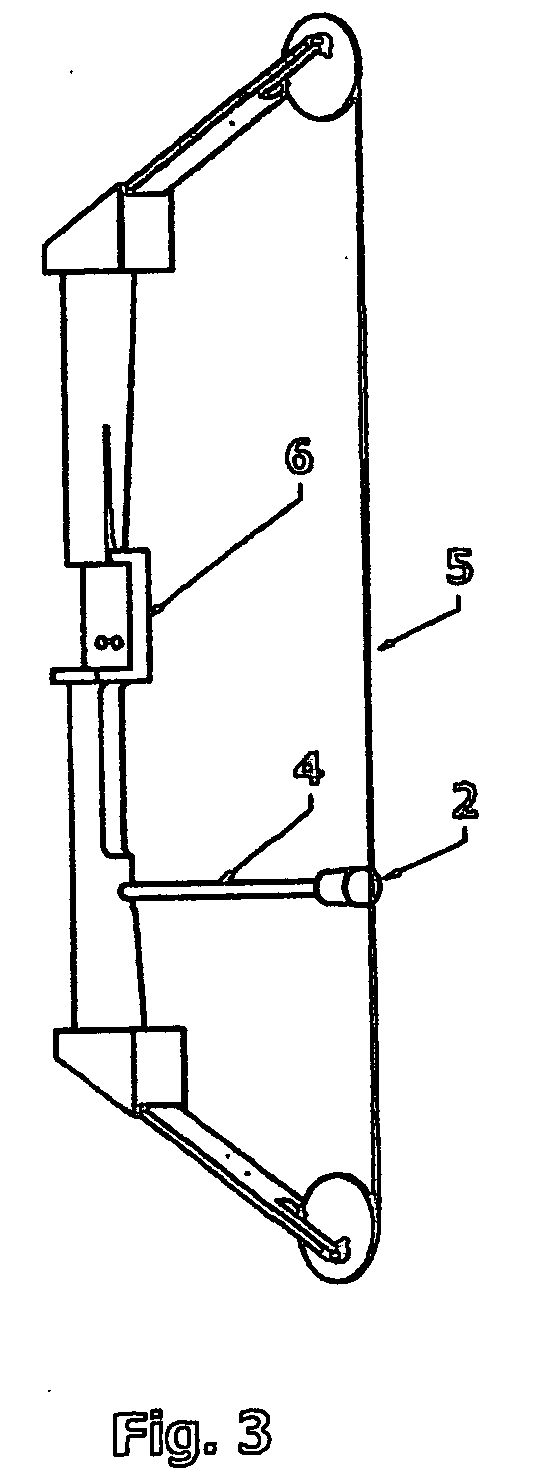

[0041]FIG. 3 shows a device used to suppress bowstring vibrations on suppressor mounting rod 4 attached to bow riser 6. The gel overmolded shell 2 is in contact with bowstring 5, when bow is at rest.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com