Shaft Structure with Configurable Bending, Weight, Moment-of-Inertia and Torque Profile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

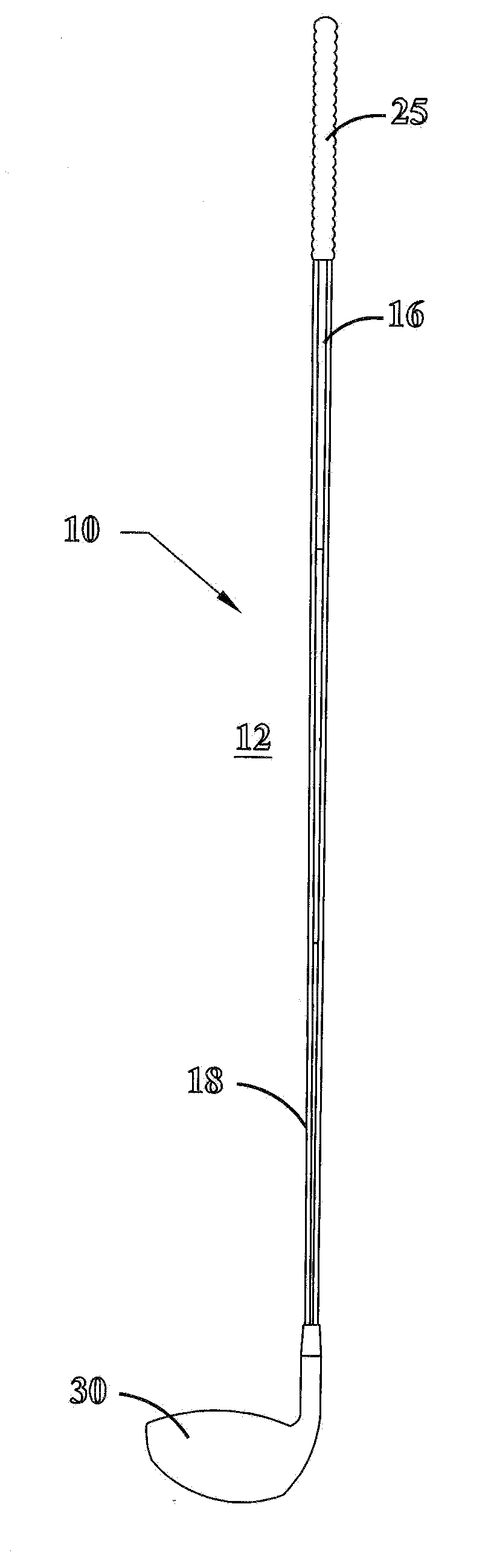

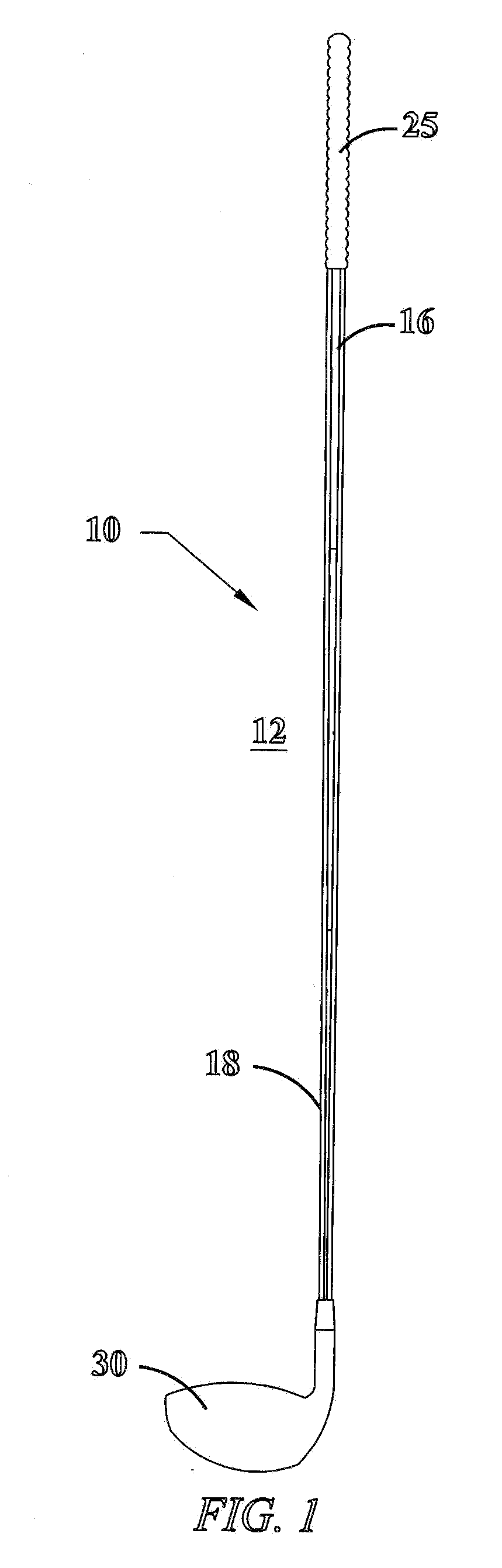

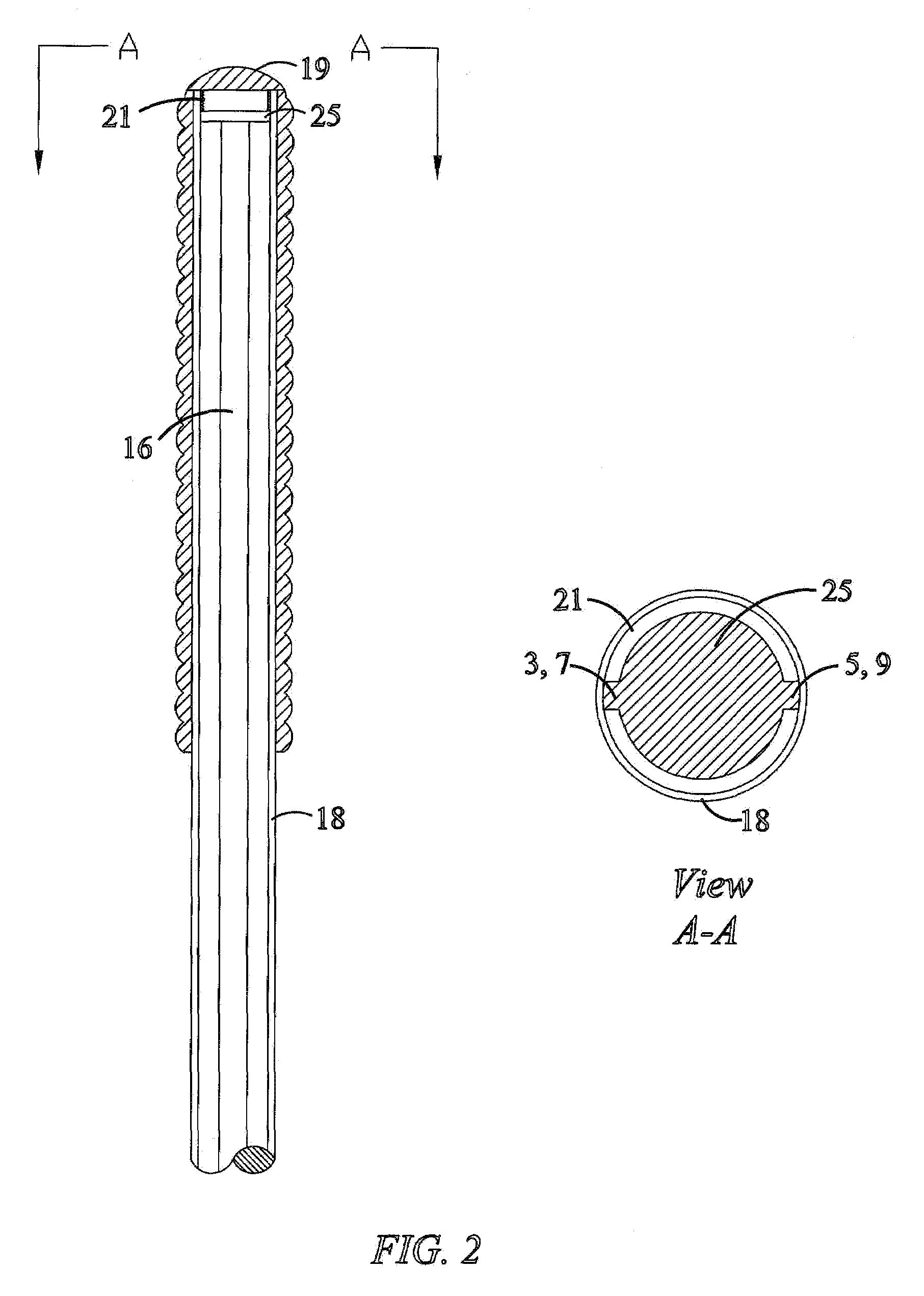

[0040]FIG. 1 reveals an illustrative golf club 10 that incorporates an embodiment of an overall shaft structure 12 of the present invention. In the preferred embodiment, overall shaft structure 12 includes an outer shaft structure 18 and an inner shaft structure 16. Both the outer shaft structure 18 and the inner shaft structure 16 are defined by a proximal and distal end. In the matter of a golf club the proximal end is accompanied by a conventional golf grip 25 whereas the distal end is accompanied by a conventional golf club-head 30. Shaft structure 12 is defined as having an overall unique bending, weight, moment-of-inertia and torque profile. The overall moment-of-inertia of shaft structure 12 is defined by the unique distribution of weight of both the outer shaft structure 18 and the inner shaft structure 16. The bending, weight, weight distribution and torque profile of the outer shaft structure 18 remains constant and fixed. The inner shaft structure 16 exhibits a bending, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com