Disposable dishwashing towel with soap and scouring power

a technology of dishwashing towels and soap, applied in papermaking, non-fibrous pulp addition, coatings, etc., can solve the problem of no cloth-like disposable paper towels, and achieve the effect of removing odors in the kitchen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

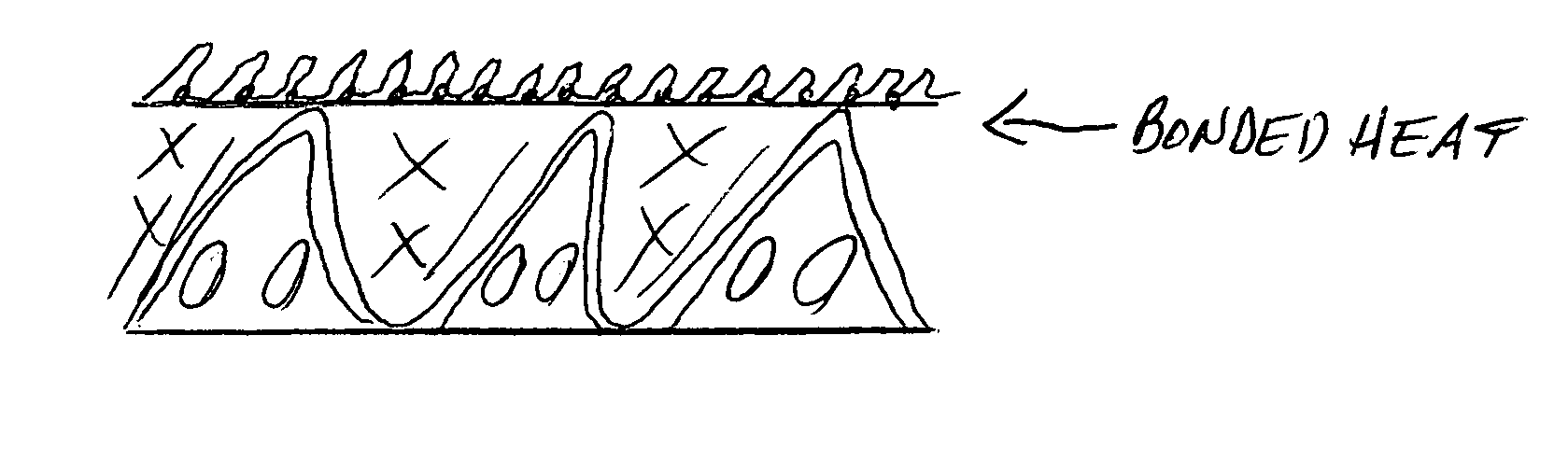

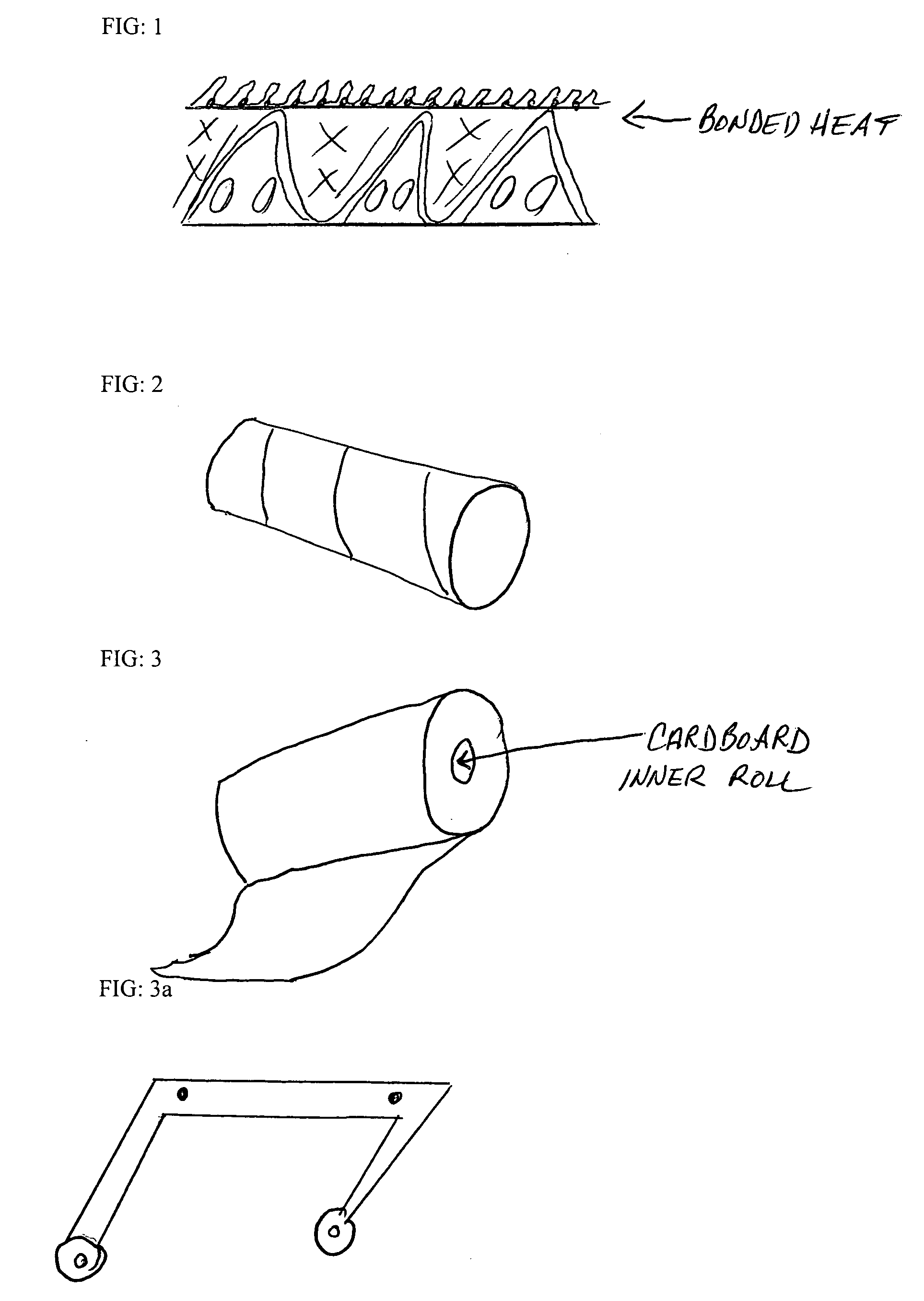

[0015]The first process of this invention comprises a number of steps or operation which occur in time sequence and are similar to how paper towels are made today, containing a network region and a plurality of domes dispersed throughout the whole of the network region. This invention is of a perforated cloth-like paper towel with a web design similar to most paper towels today, but containing a dry soap formula sprayed into the towel during the paper making process and coated with a rigid or semi rigid plastic with an abrasive texture that measures 0.2-1 ml thick.

[0016]Because this paper towel is cloth-like it will be durable. It will be strong enough to withstand friction and have the ability to scrub without falling apart. This towel will be similar in structure and design to most paper towels on the market today, however this improved cloth-like paper towel is designed to be stronger and provide the scouring

[0017]This disposable dishwashing cloth-like paper towel with soap will ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| durability | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com