Latching system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

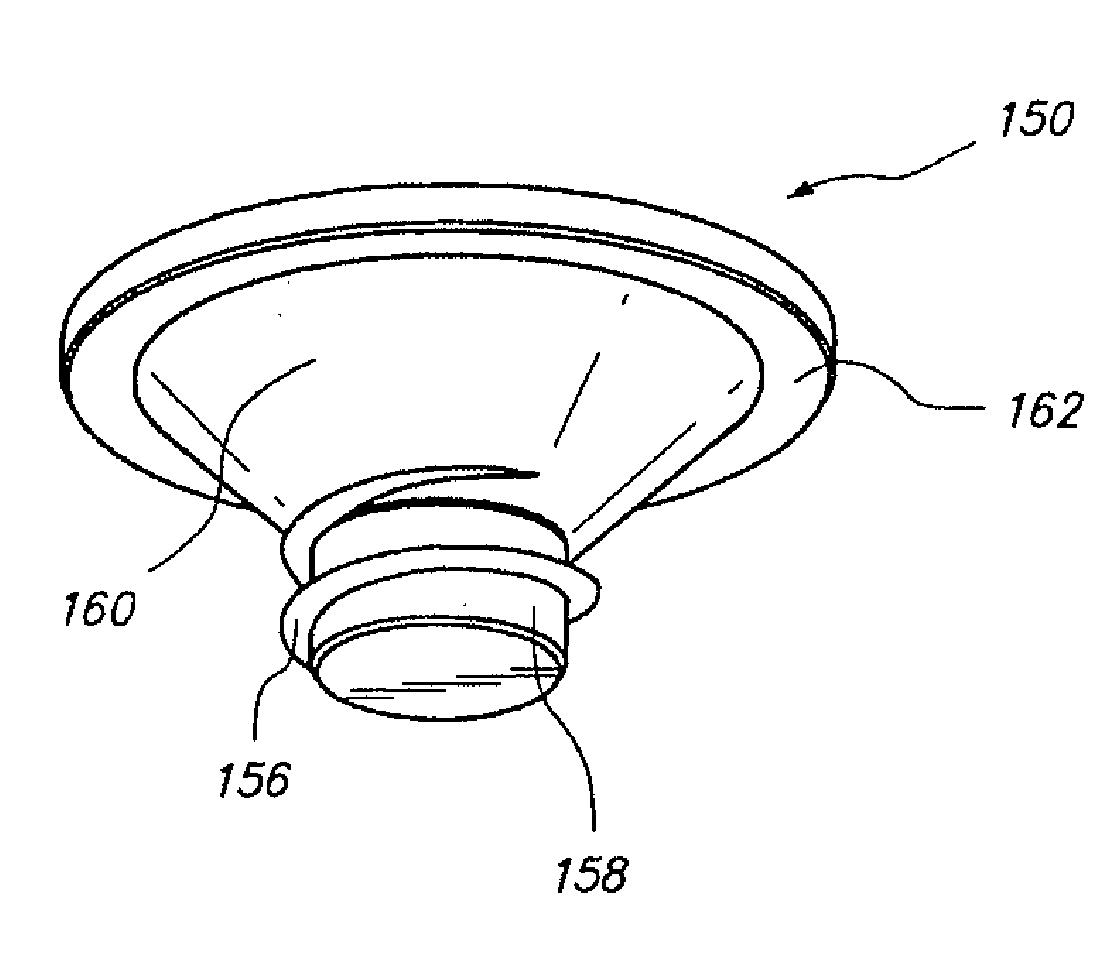

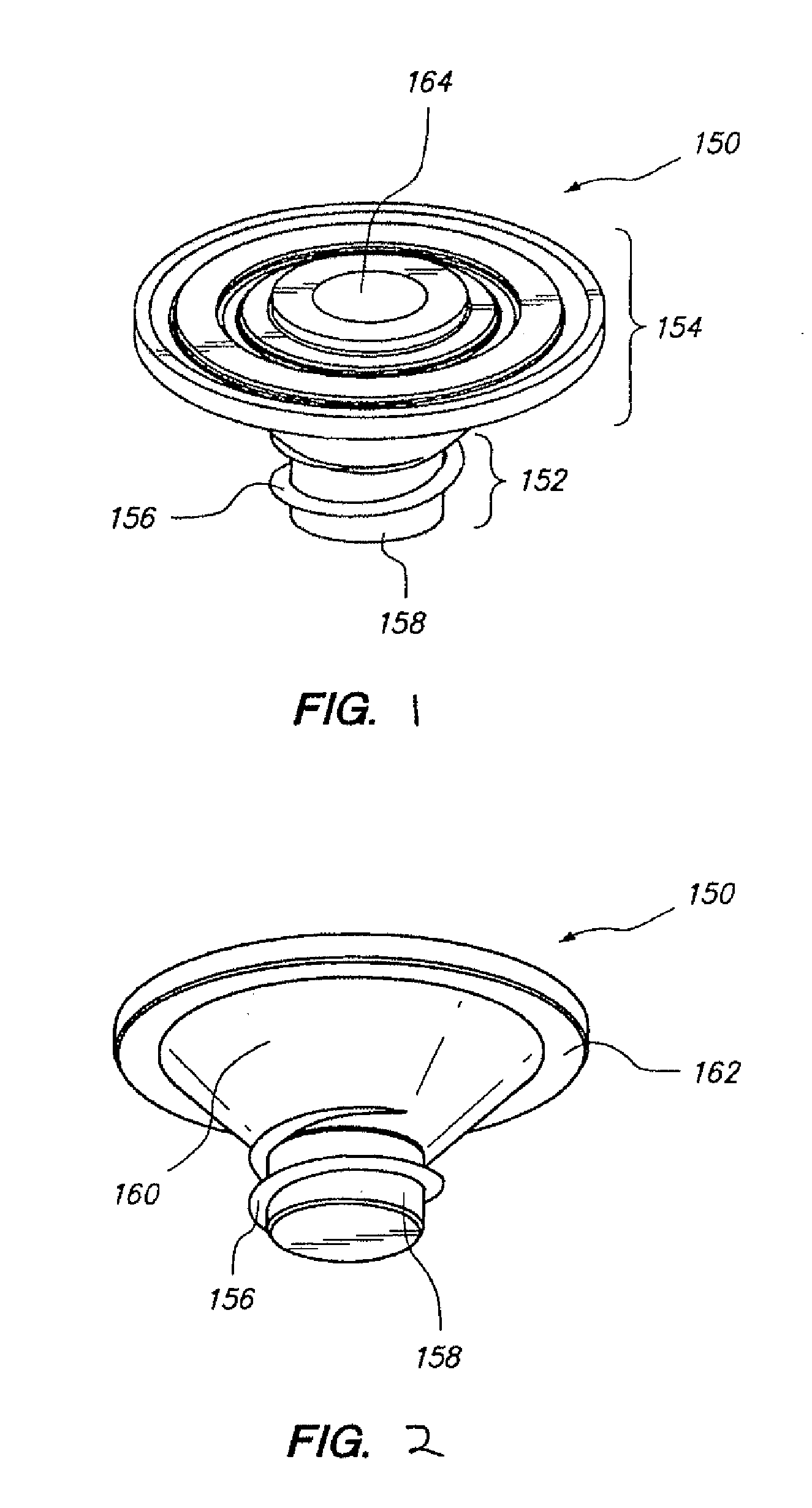

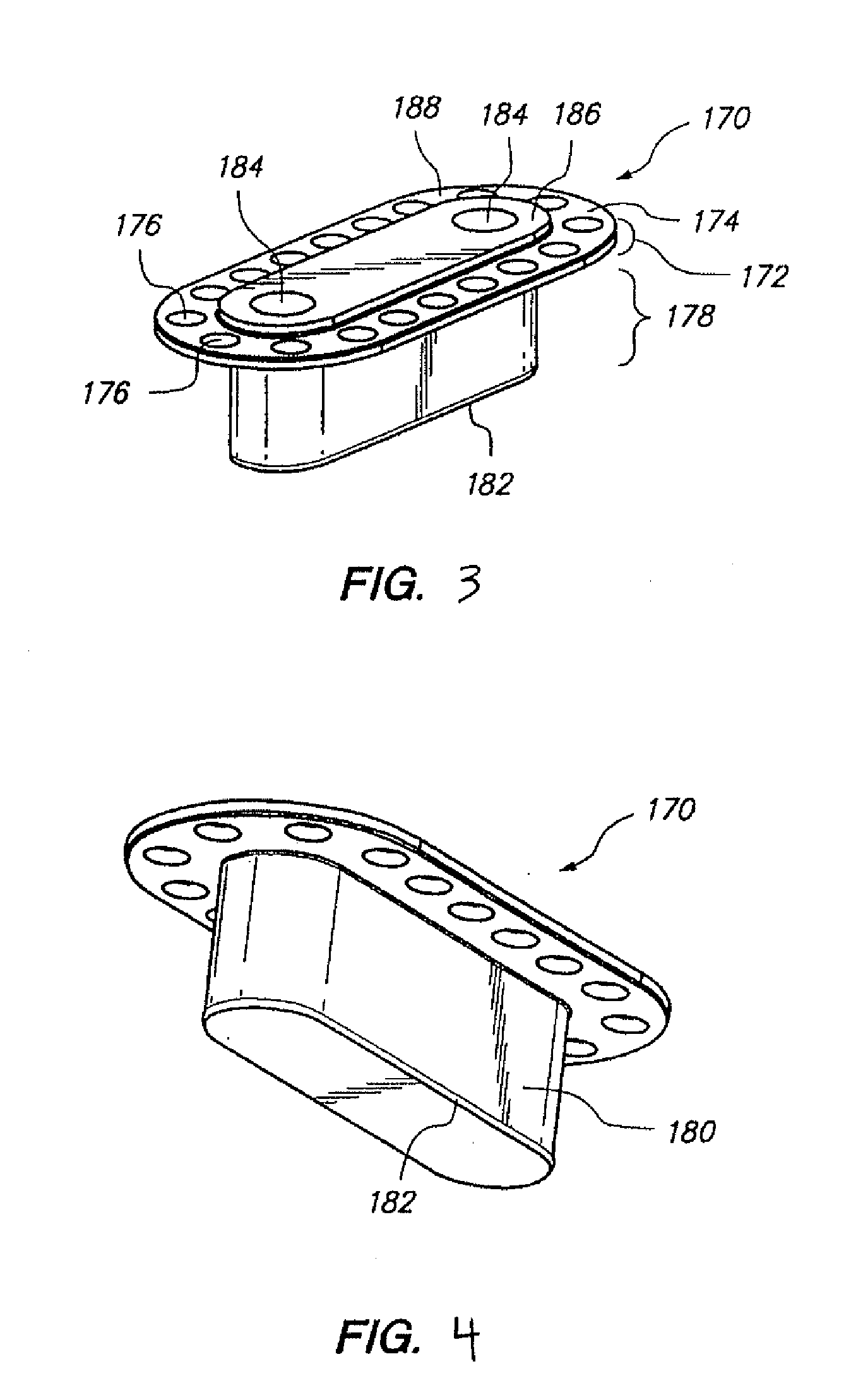

[0075]Embodiments disclosed herein relate to attachment methods and devices that utilize locking forces to securely attach a device to an object yet facilitate simple and easy detachability. The attachment methods and devices disclosed herein are applicable to a wide range of objects and devices. As discussed below, the attachment methods and devices disclosed herein can be advantageously used to couple a device to an object, wherein the device extends vertically from the object when attached, and is likely to encounter horizontal forces when attached to the object. For example, the attachment mechanisms disclosed herein can be used to attach a fin to a surfboard or other watercraft, a cleat to a shoe, a wheel truck to a rollerskate, rollerblade, or skateboard deck, a blade to an ice skate, components of components of furniture, or various other device / object pairs.

[0076]As discussed below, some embodiments disclosed herein relate to attachment devices and methods that utilize sprin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Force | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com