System for transporting and installing roof trusses

a technology for installing trusses and roofs, which is applied in the direction of transportation and packaging, conveyor parts, building roofs, etc., can solve the problems of unsatisfactory common system for installing trusses for building roofs, lack of stability, and difficulty in handling, and achieves convenient installation and efficient and inexpensive transportation of trusses.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

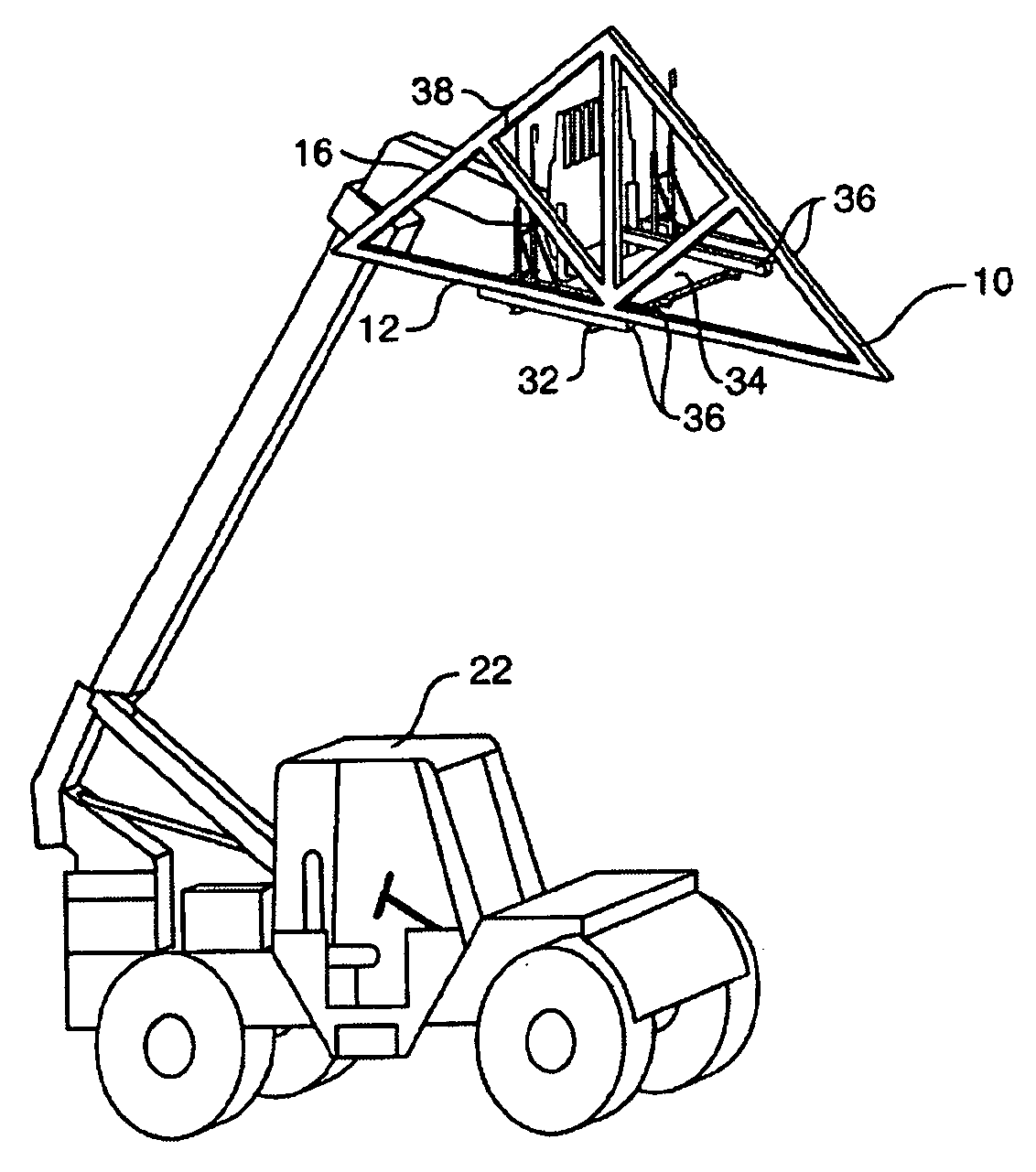

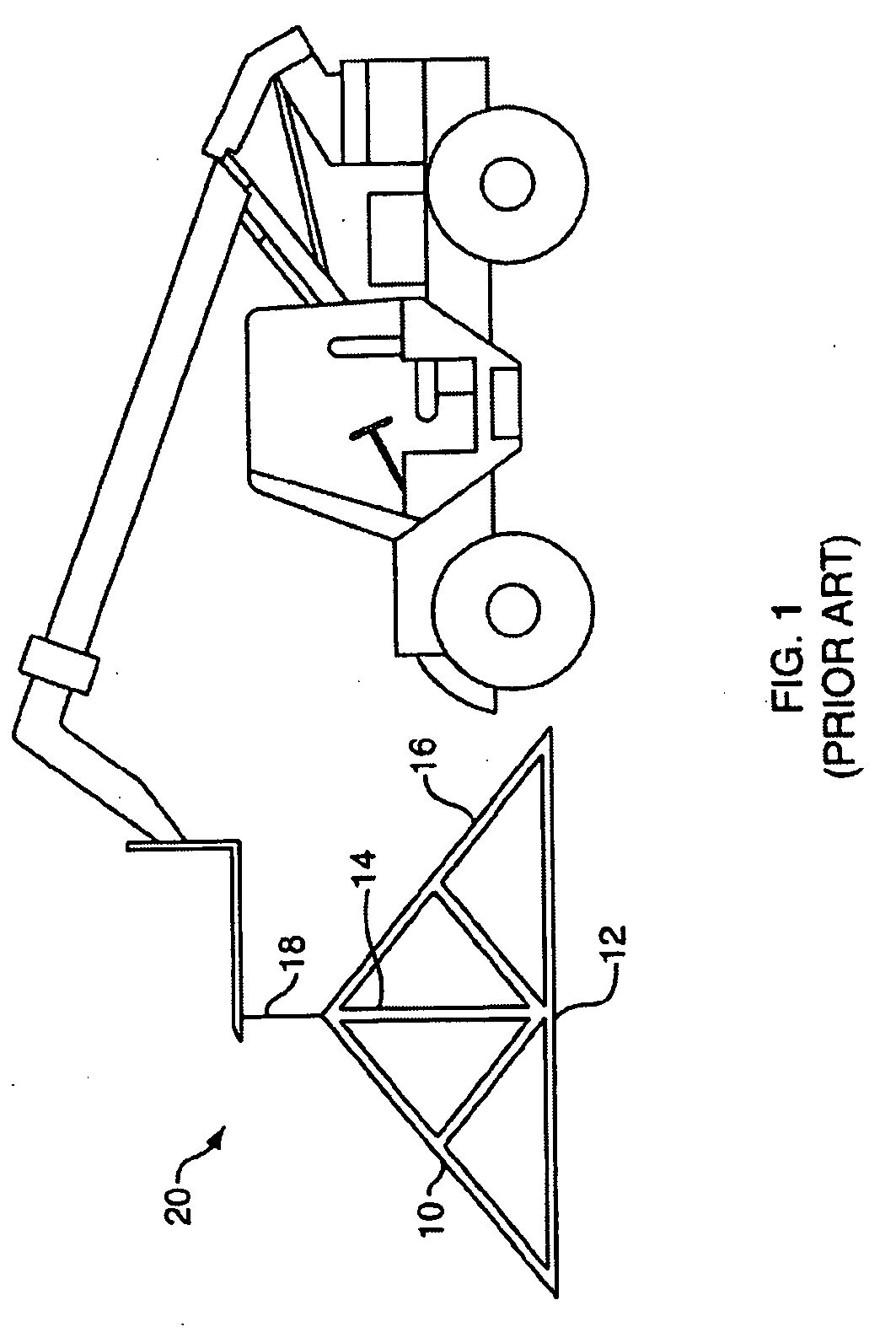

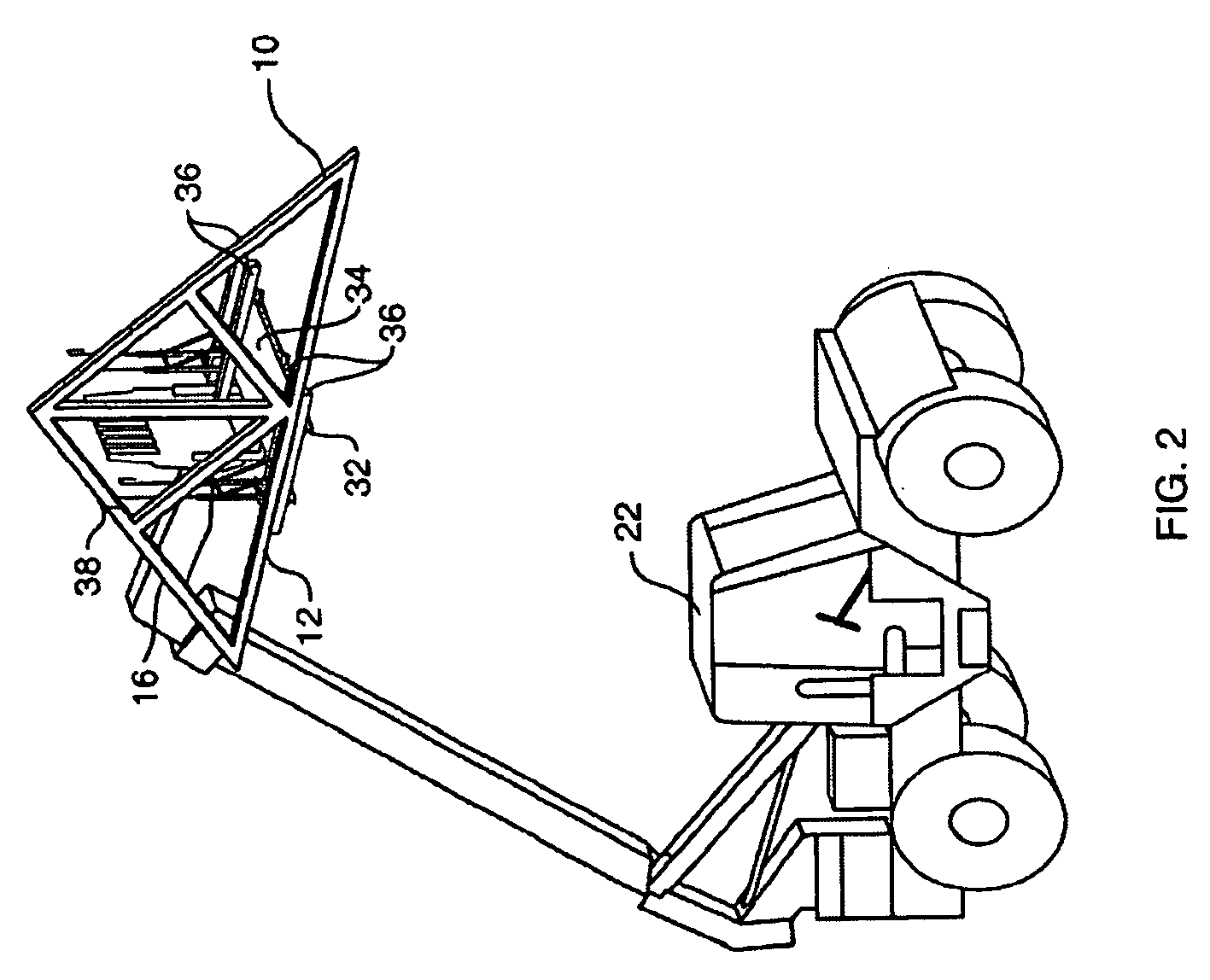

[0030]The present invention is a system for transporting and installing building roof trusses. A preferred embodiment of the present invention is shown in use in FIG. 2. It should be noted that although the preferred embodiment of the present invention described at length here is a system for roof trusses, the present invention can also be used for other commonly used construction materials that can fit into a channel and that need to be delivered to a higher location.

[0031]Referring to FIG. 2, a truss handling apparatus 30 of the invention interacting with the forks 20 of a lift 22 is shown. The truss handling apparatus 30 has a base 32 with a platform 34 and a plurality of channels 36. One of the channels 36 is shown retaining the base 12 of the truss. The truss handling apparatus 30 in addition has a retaining device 38 which engages the sloping side rafters 16 of the truss 10. As can readily be seen, the truss 10 is transported on top of, and parallel to, the forks 20 of the lif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com