Heat dissipation fan

a heat dissipation fan and fan body technology, applied in the direction of non-positive displacement fluid engines, piston pumps, pump components, etc., can solve the problems of increased friction between the shaft and the bearing, deterioration of the performance of the heat dissipation fan, and noise or malfunction of uncomfortable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Reference will now be made to the drawings to describe the various present embodiments in detail.

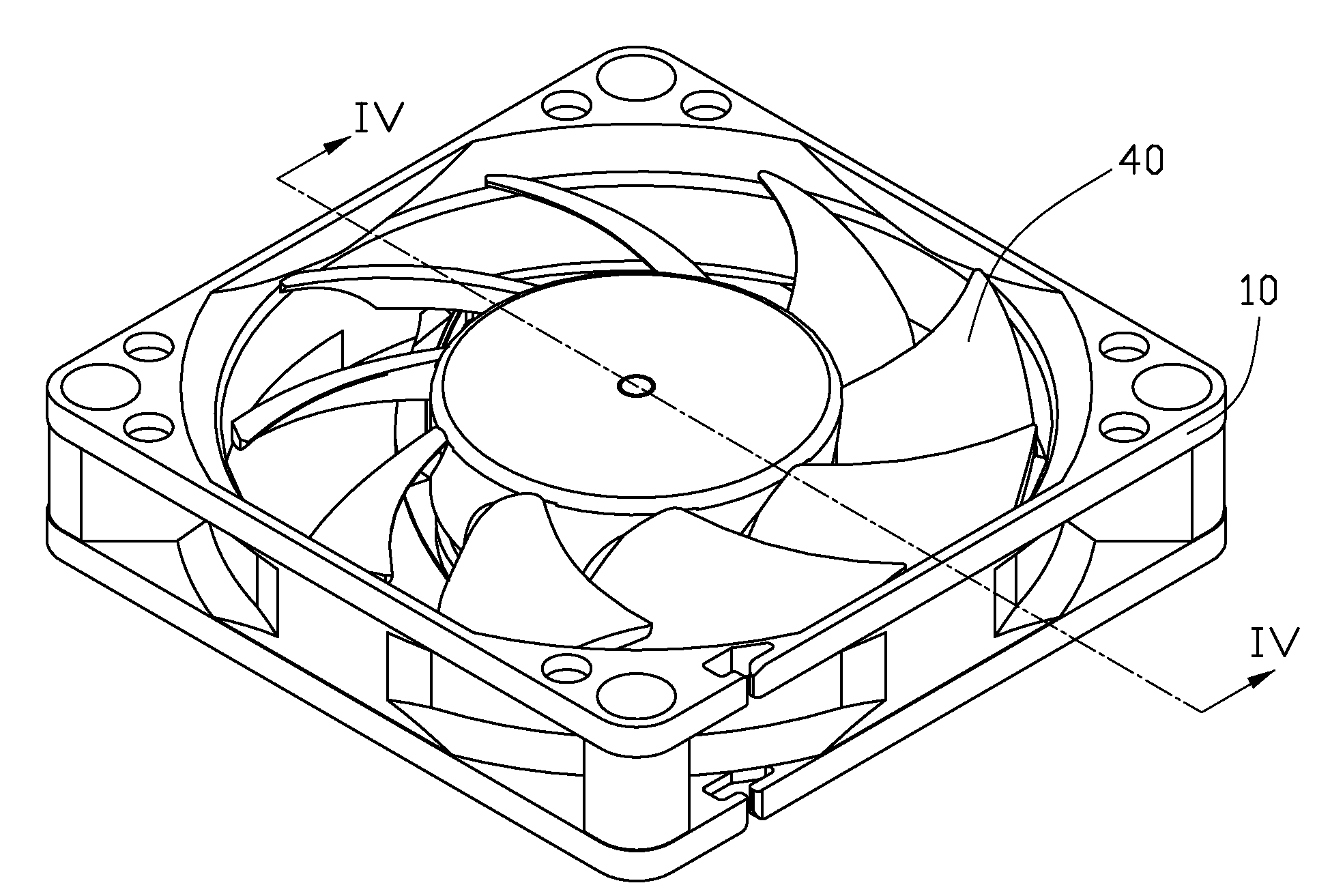

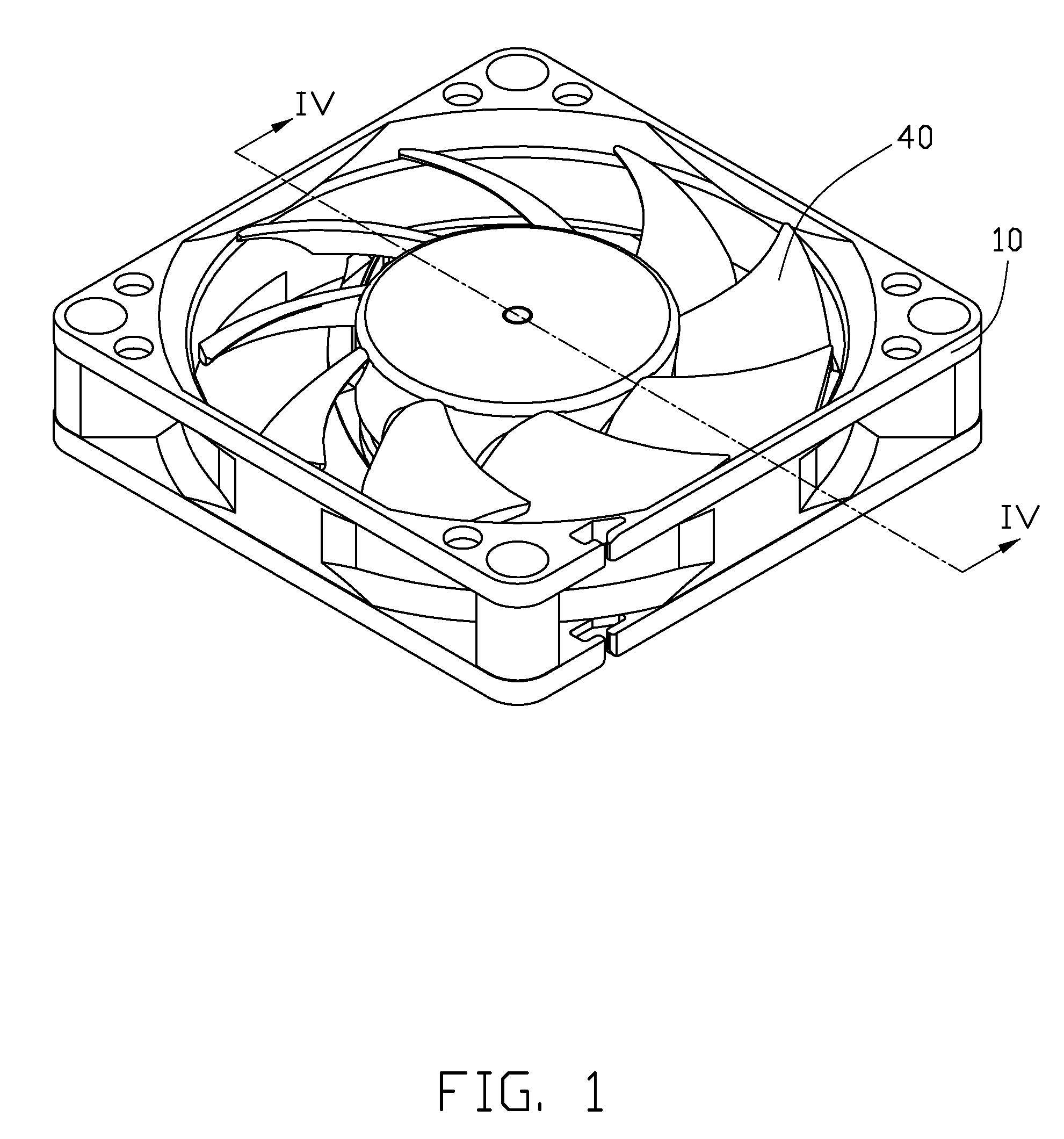

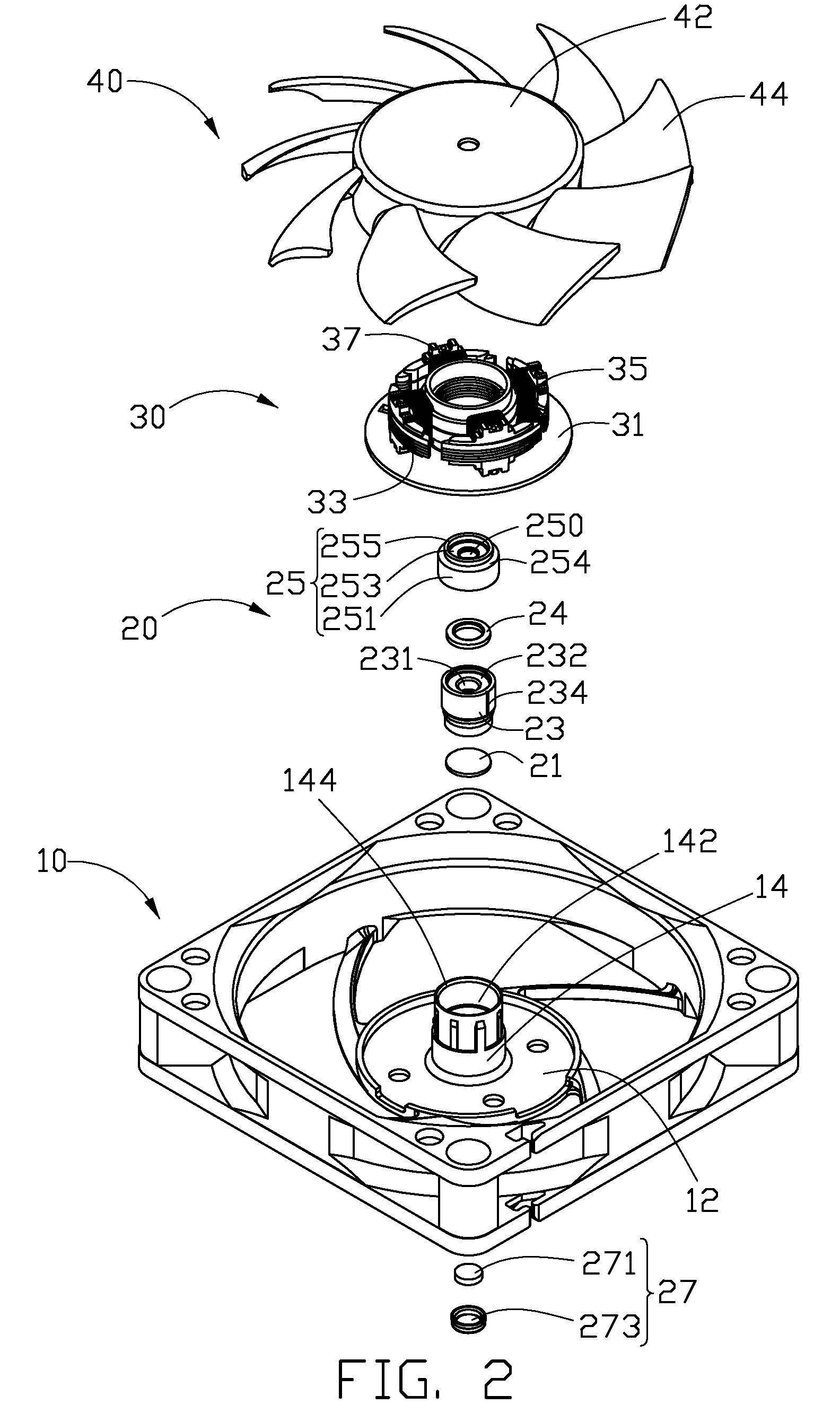

[0015]Referring to FIGS. 1-3, a heat dissipation fan according to an embodiment includes a rotor 40, a stator 30 in respect to which the rotor 40 is rotatable, a fan housing 10 receiving the rotor 40 and the stator 30 therein, and a bearing assembly 20.

[0016]The fan housing 10 comprises a base 12 and a central tube 14 extending upwardly from a top surface of a central portion of the base 12. The central tube 14 defines a central hole 142 therein and forms an open end at a top portion thereof. An annular recess 144 is formed on an inner circumference of the top portion of the central tube 14. The annular recess 144 communicates with the central hole 142. The top portion of the central tube 14 has an inner diameter which is larger than that of the other portion of the central tube 14. A receiving concave 120 is formed on a bottom surface of the central portion of the base 12. The rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com