Medical closure device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

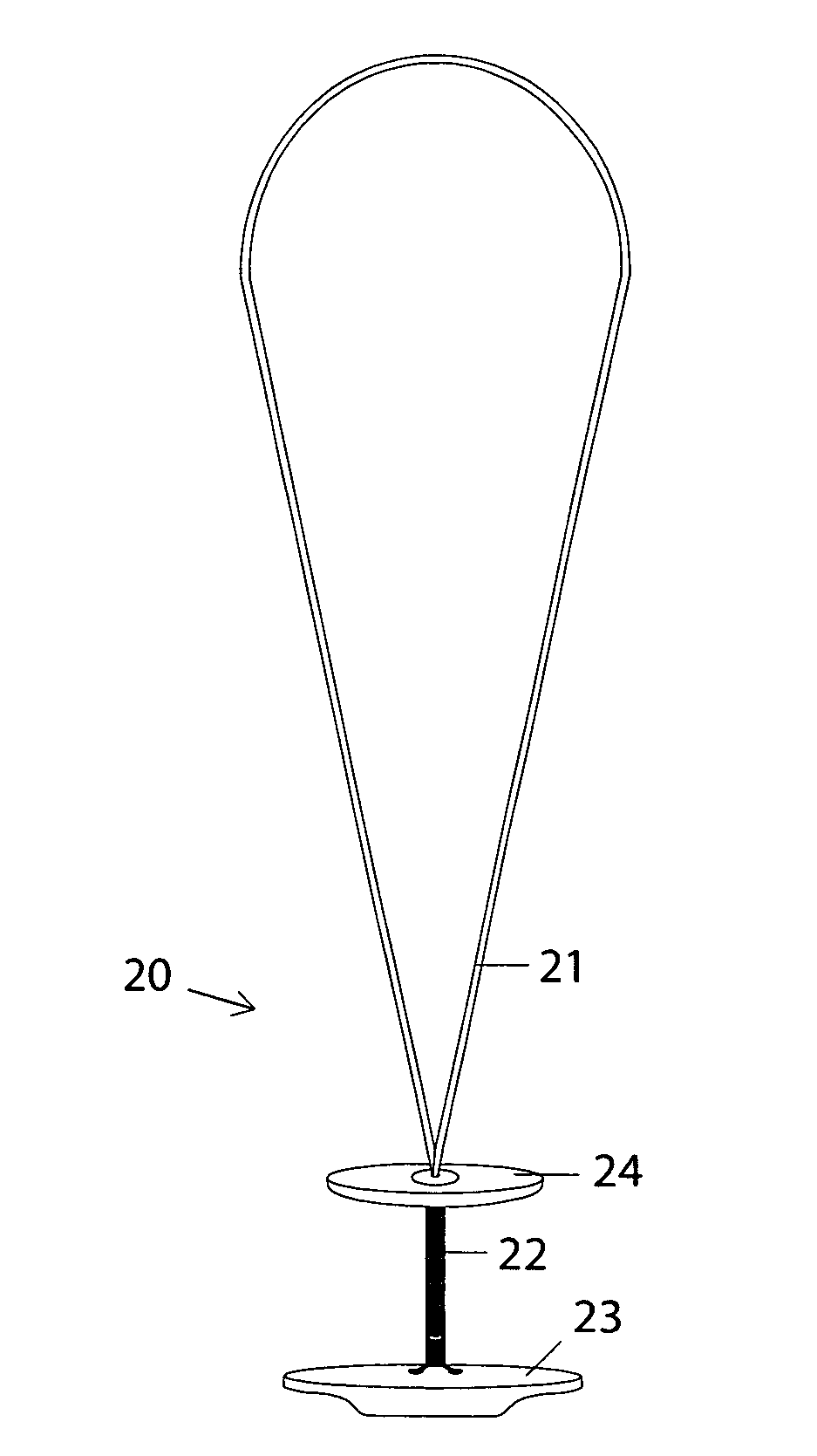

[0017]In FIG. 1a, a sealing device 1 comprising an inner member 2 and retaining member 3 in the form of a loop 3 according to the present invention is schematically illustrated. The inner member 2 is adapted to be introduced into a vessel (for example, a blood vessel) and positioned at an inner surface of the vessel wall, where the inner member 2 is held in place by tension applied in the retaining member 3. The retainer loop 3 has been created by winding up a thin filament multiple times such that the loop 3 has several coils of the same filament. Depending on in particular the surface characteristics of the filament used, the number of windings can easily be made sufficiently large such that a loop that holds together without the use of, for example, a knot or glue is produced. To prevent any tendency of the filament coils to fray, an adherent, like wax or suture coating, can be applied to the surface of the filament during winding. As an alternative, an adherent could be applied ...

second embodiment

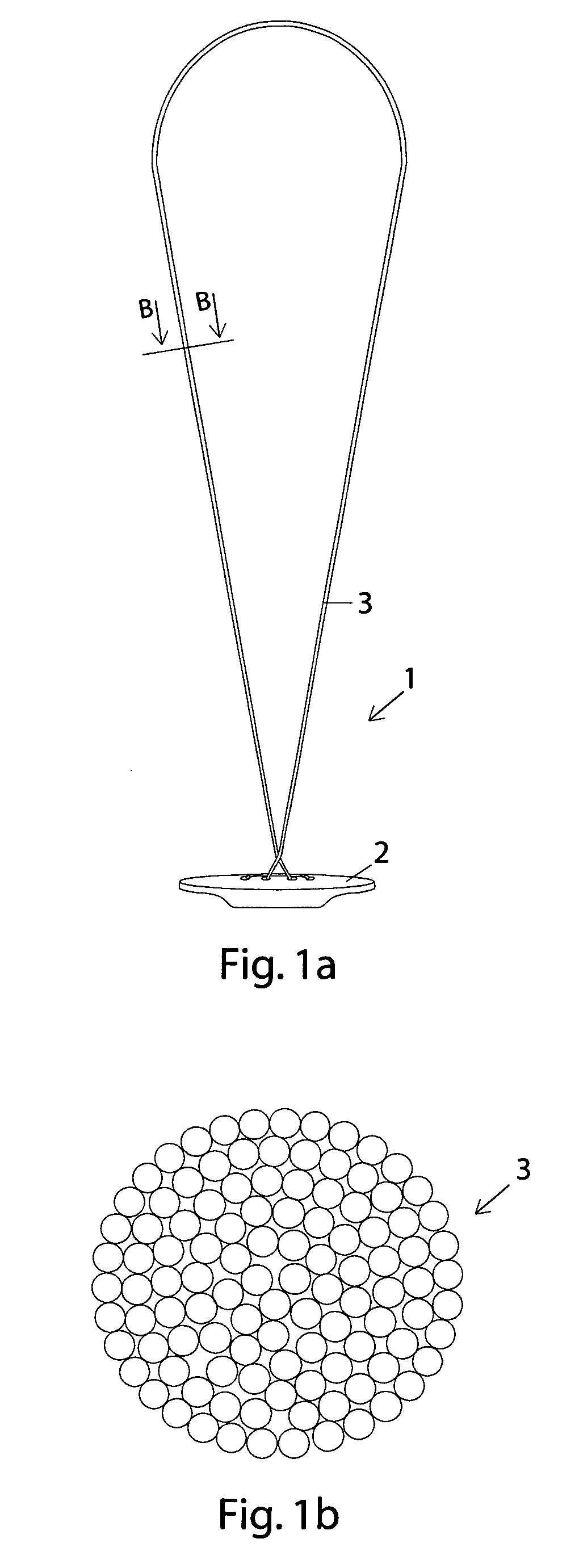

[0019]In FIG. 2 a cross-section of a loop 13 according to the present invention is schematically illustrated. In this embodiment, several monofilaments have simultaneously been wound multiple times to create a composite loop 13. For illustrating purposes the number of monofilaments has been reduced to five (5), and the number of turns is ten (10), resulting in that each monofilament appears ten times in the cross-section and that the cross-section comprises a total of fifty (50) individual monofilament cross-sections. In practise, it may be preferred that these numbers, for example, are doubled, i.e. the number of monofilaments is ten (10) and the number of coils is twenty (20). It should, however, be emphasized that for a given situation, the adequate number of monofilaments as well as the adequate number of turns are very easily established by a few simple trials.

[0020]A similar way of manufacture a loop comprising multiple coils of the same filaments is to wind a multifilament mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com