Paint brush

a paint brush and ferrule technology, applied in the field of paint brushes, can solve the problems of plastic handles that are not biodegradable, plastic ferrules suffer from the same flaws plastic ferrules suffer from the same problems as plastic paintbrush handles, so as to achieve the effect of superior material, not having a negative environmental impact, and being lightweight and durabl

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

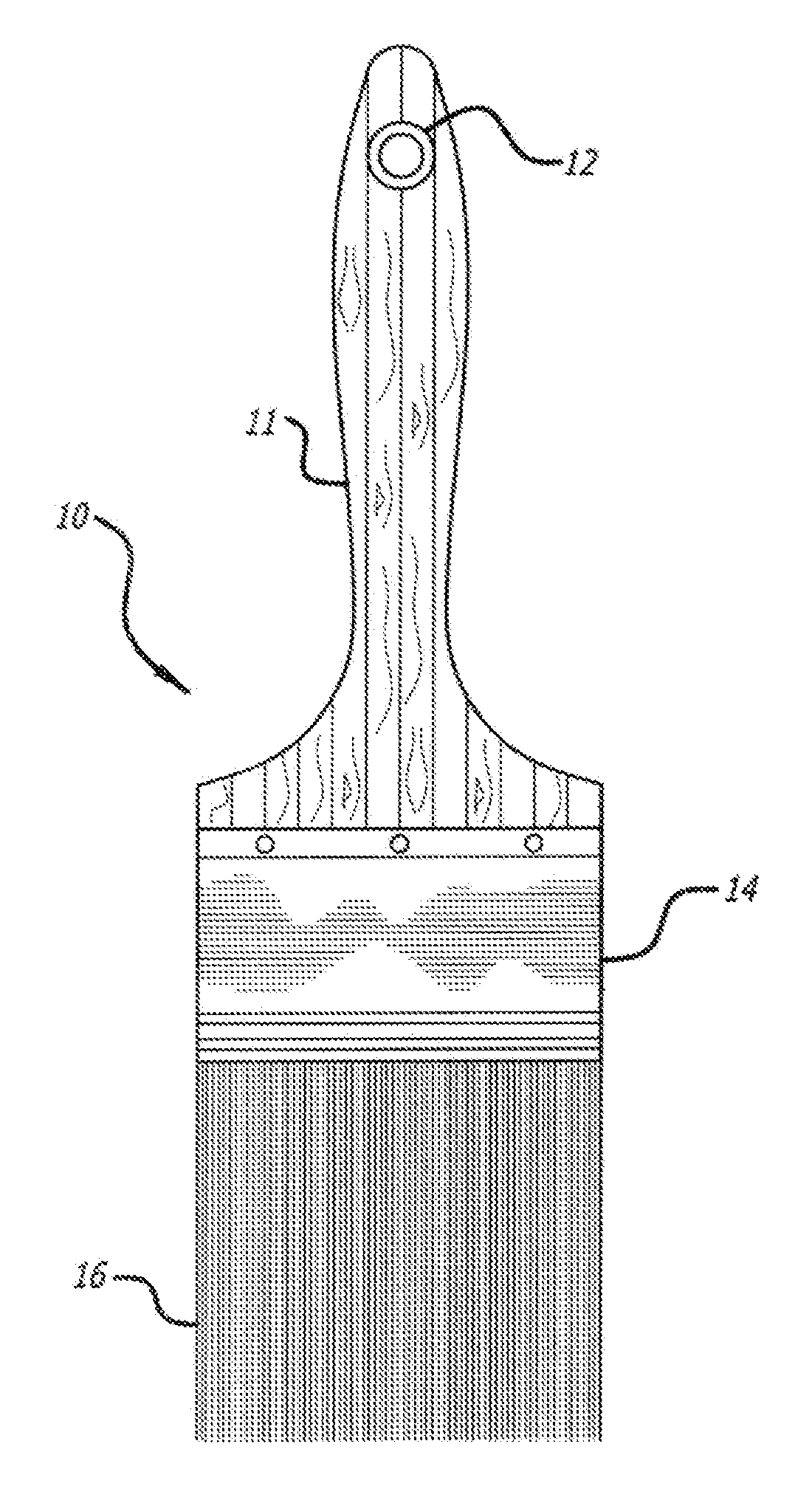

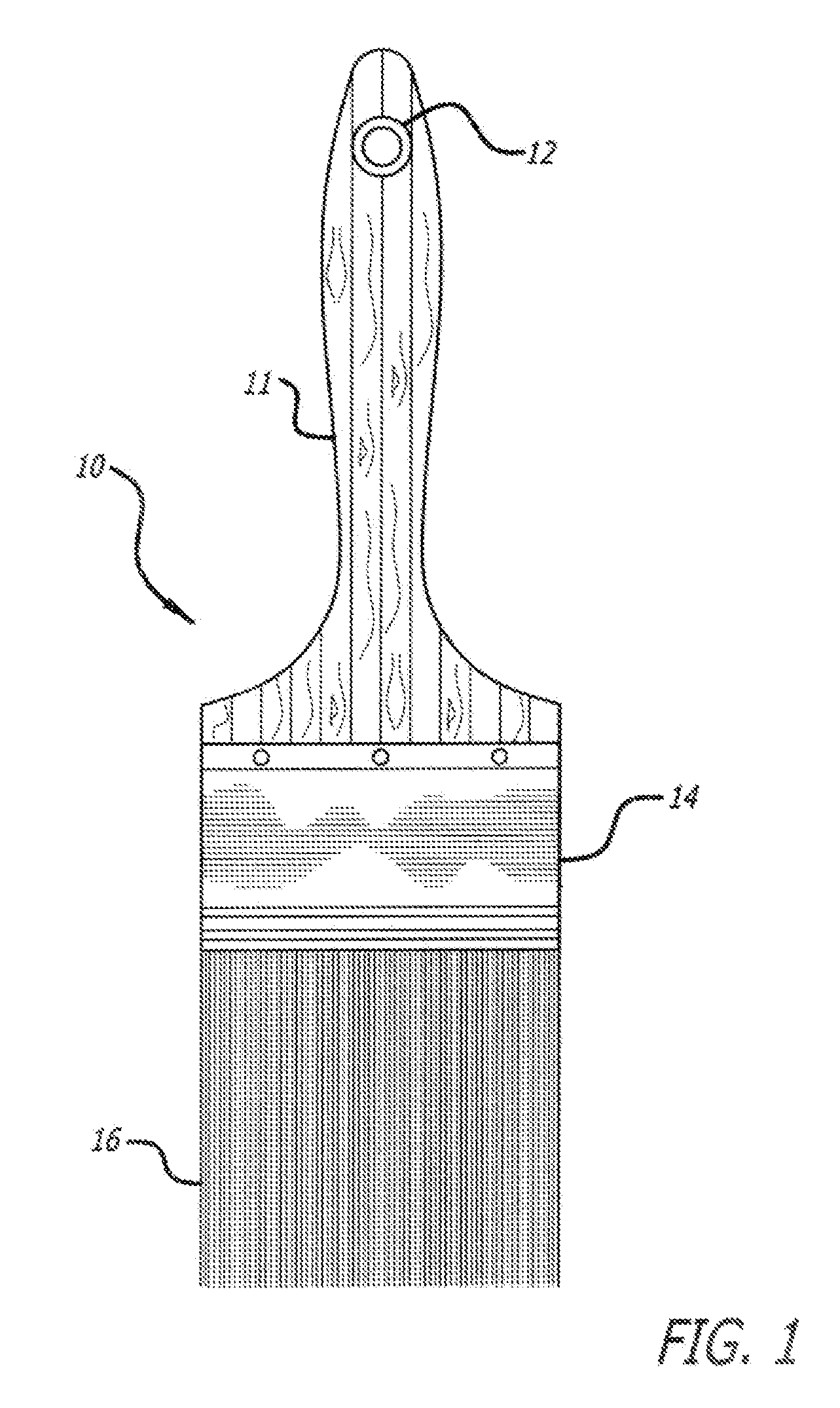

[0020]Referring to FIG. 1, a plan view of one embodiment of the improved paintbrush 10 of the present invention is demonstrated. The handle 11 of the paintbrush is composed of bamboo. The handle 11 contains a beveled hang-up hole 12 near the top of the handle 11.

[0021]The handle 11 is formed from laminated bamboo. The handle 11 is prepared by super heating the bamboo in water, pressurizing the bamboo and then forming it into laminated sheets using glue. Further details of the lamination process are well known to those skilled in the art. Forming the handle 11 of laminated bamboo confers several advantages on the paintbrush 10. The paintbrush 10 with a laminated bamboo handle 11 is lighter and stronger than paintbrushes composed of conventional wood materials. Additionally, bamboo replenishes itself over a period of months, whereas the trees that produce wood for conventional handles take decades to replenish themselves. Therefore, bamboo handled paintbrushes 10 exert a significantly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com