System For Recycling Printed Circuit Boards

a technology of printed circuit boards and recycling systems, applied in the manufacture of final products, electrolysis components, instruments, etc., can solve the problems of heavy metals that can seep into ground water and contaminate water supplies, and large amounts of obsolete electronic products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

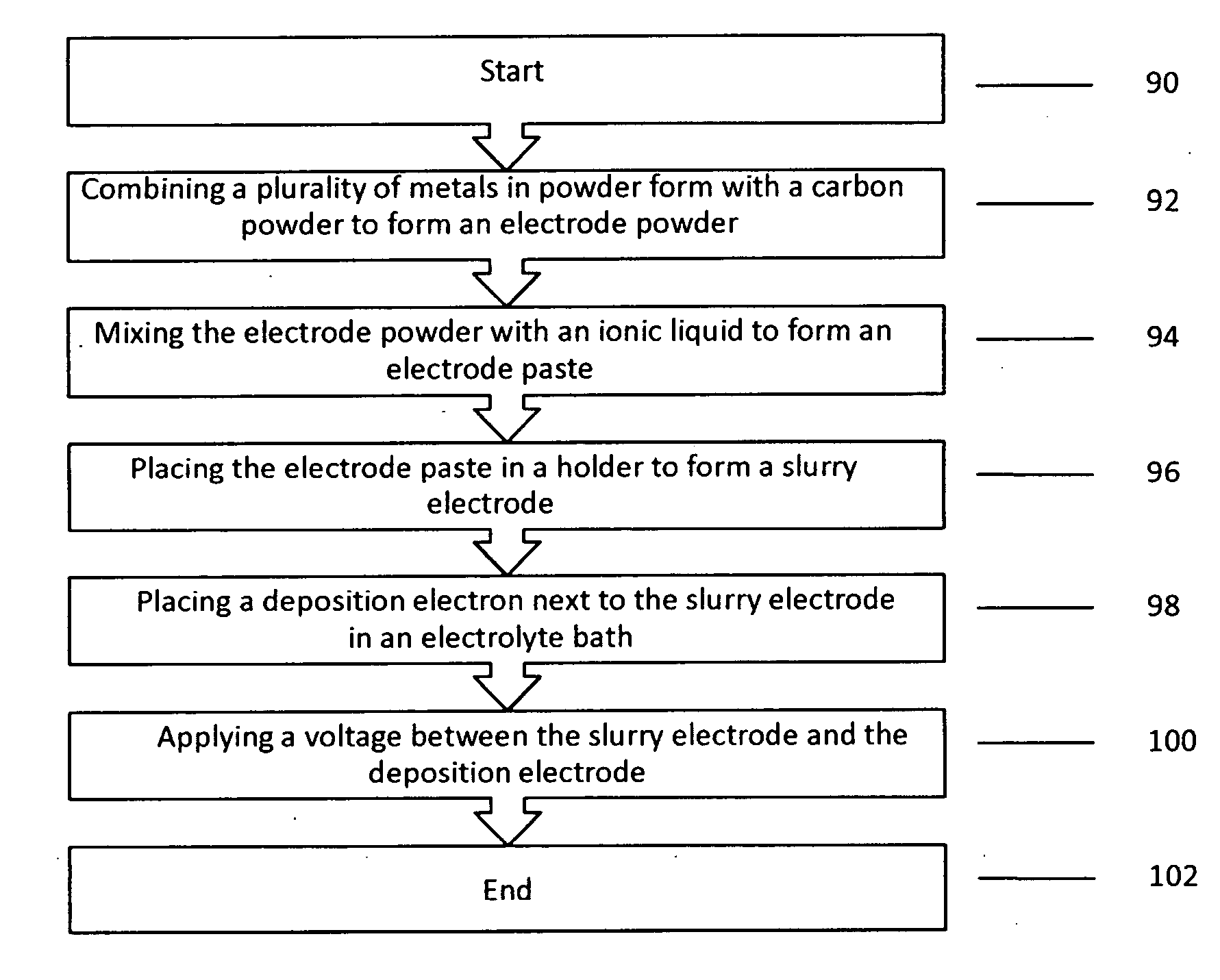

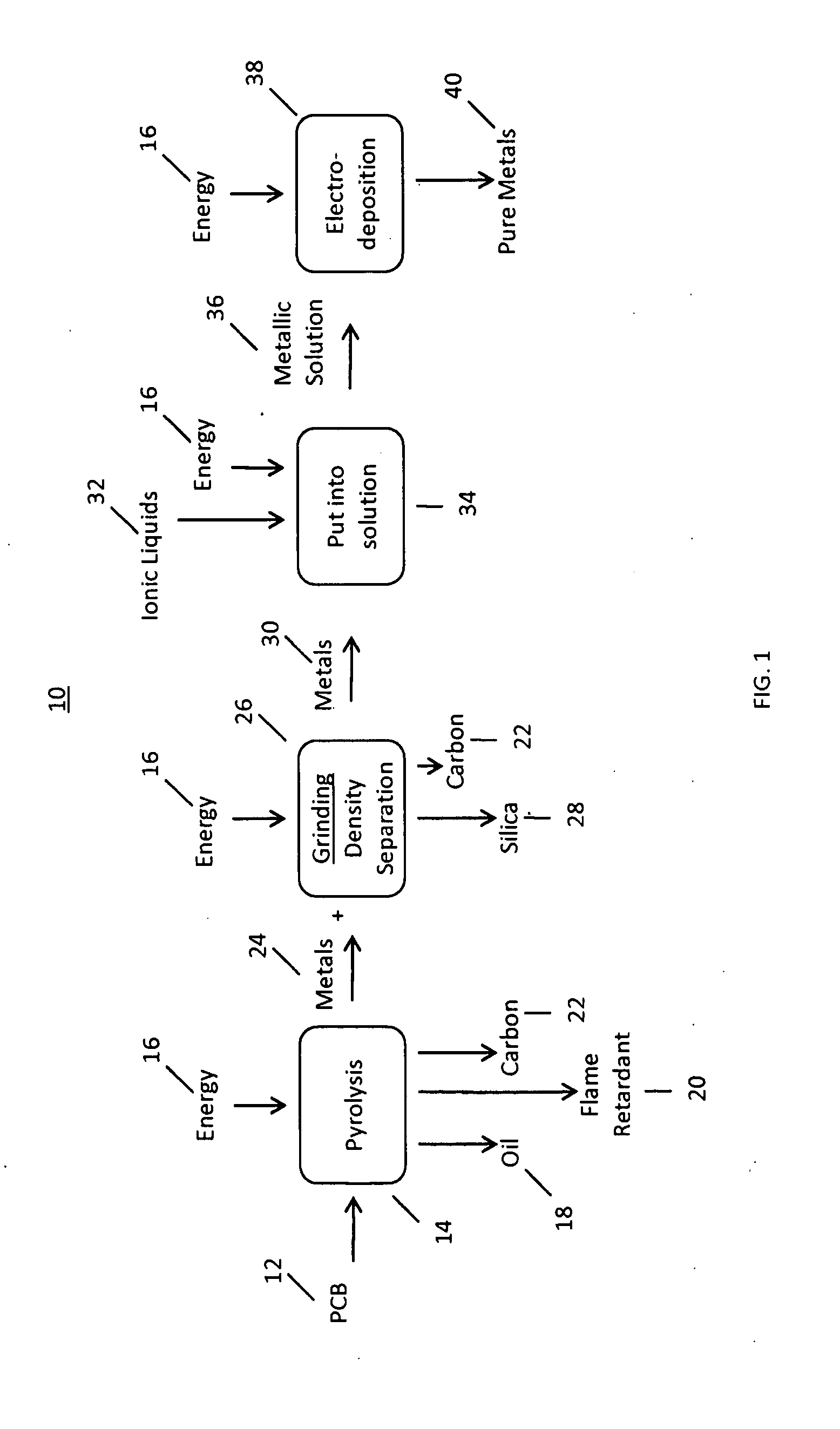

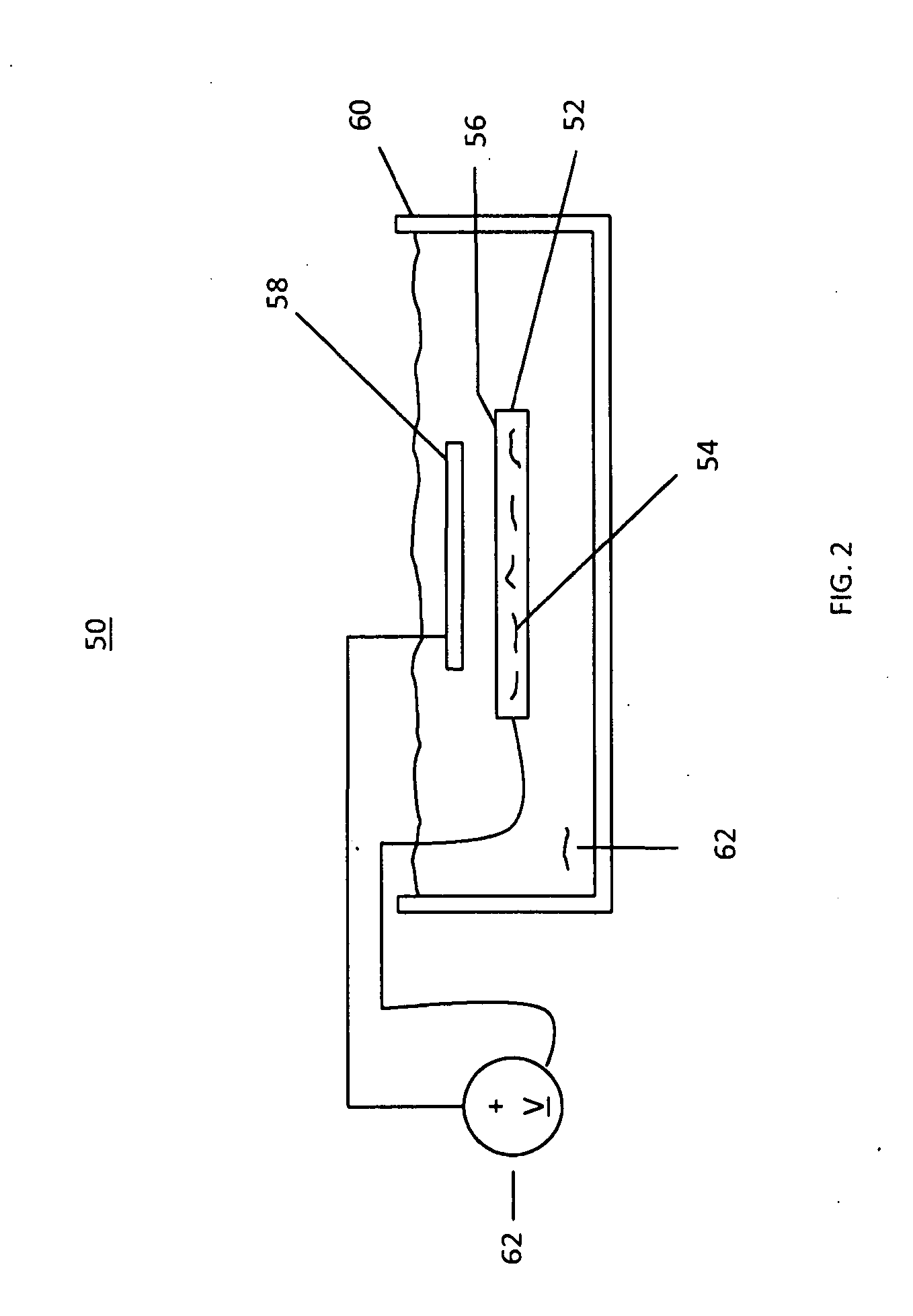

[0012]A process for recycling printed circuit boards includes pyrolyzing a number printed circuit boards to from an ash. Metals form the circuit boards are separated from the ash by density separation techniques. The metals are formed into a slurry electrode. The slurry electrode and a deposition electrode are placed in an electrolyte bath and the metals are electrorefined to form bars of metal.

[0013]FIG. 1 is a block diagram of a process 10 of recycling printed circuit boards in accordance with one embodiment of the invention. The process 10 starts with printed circuit boards (PCBs) 12 undergoing pyrolysis 14. The pyrolysis machine 14 requires energy 16 and has outputs of crude oil 18, and flame retardants 20. The crude oil 18 can be reused as fuel oil or as feedstock. The flame retardant 20 can either be disposed of safely or reused. The carbon 22 can be added to fertilizer or safely land filled. The other output of the pyrolysis 14 is an ash containing metals and silica 24 and ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ionic | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

| current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap