Air Flow Control Method and System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

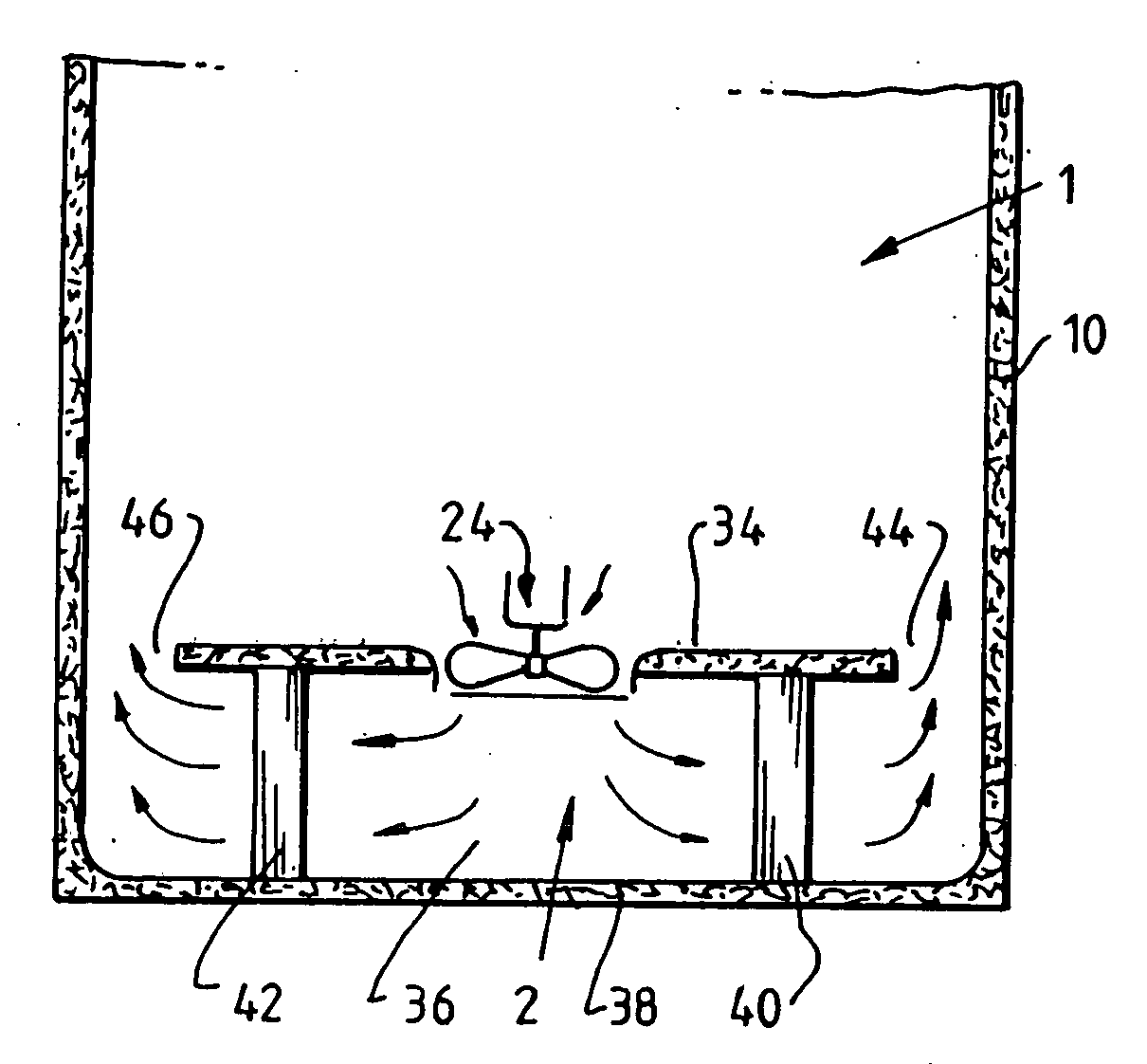

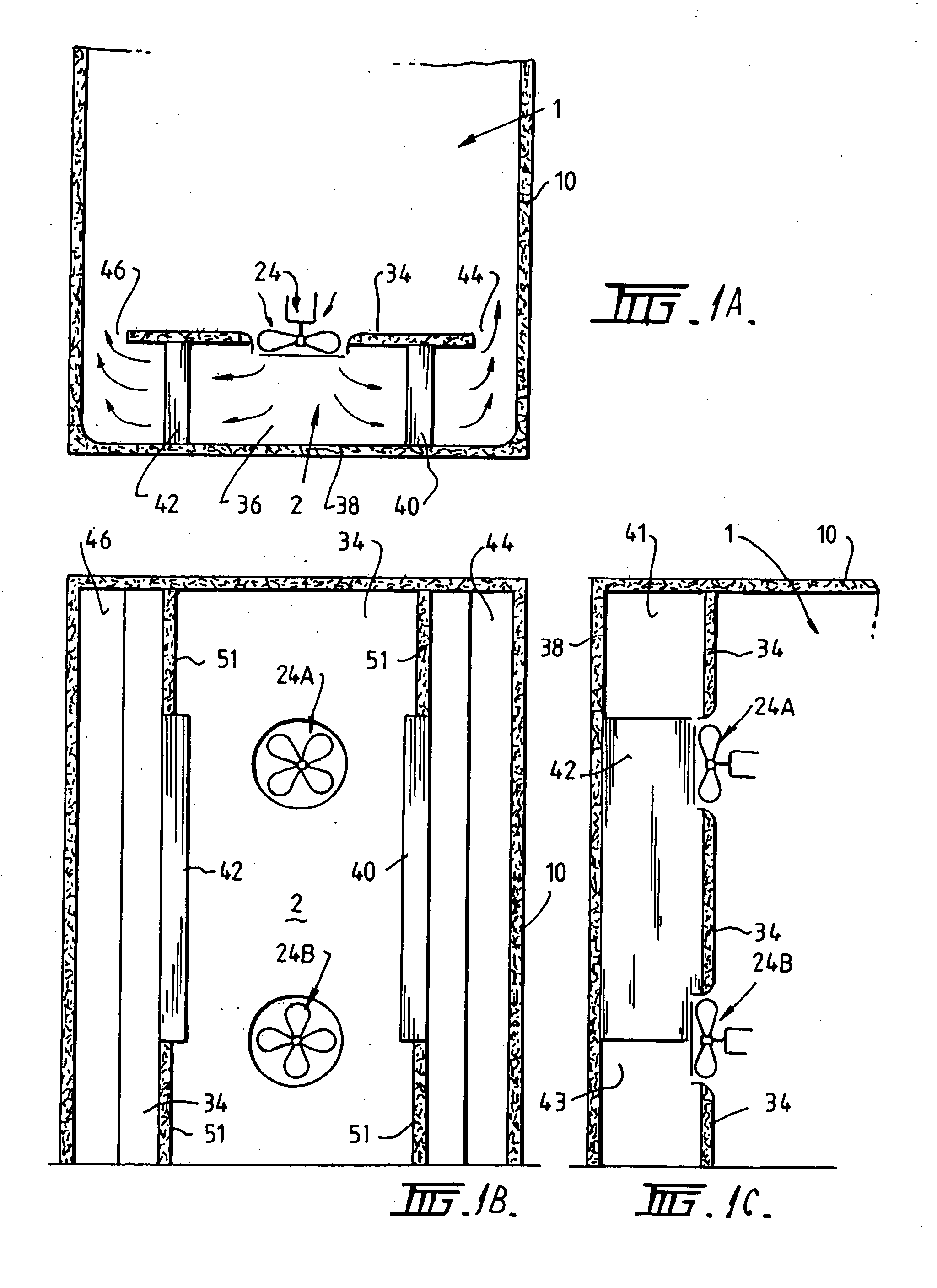

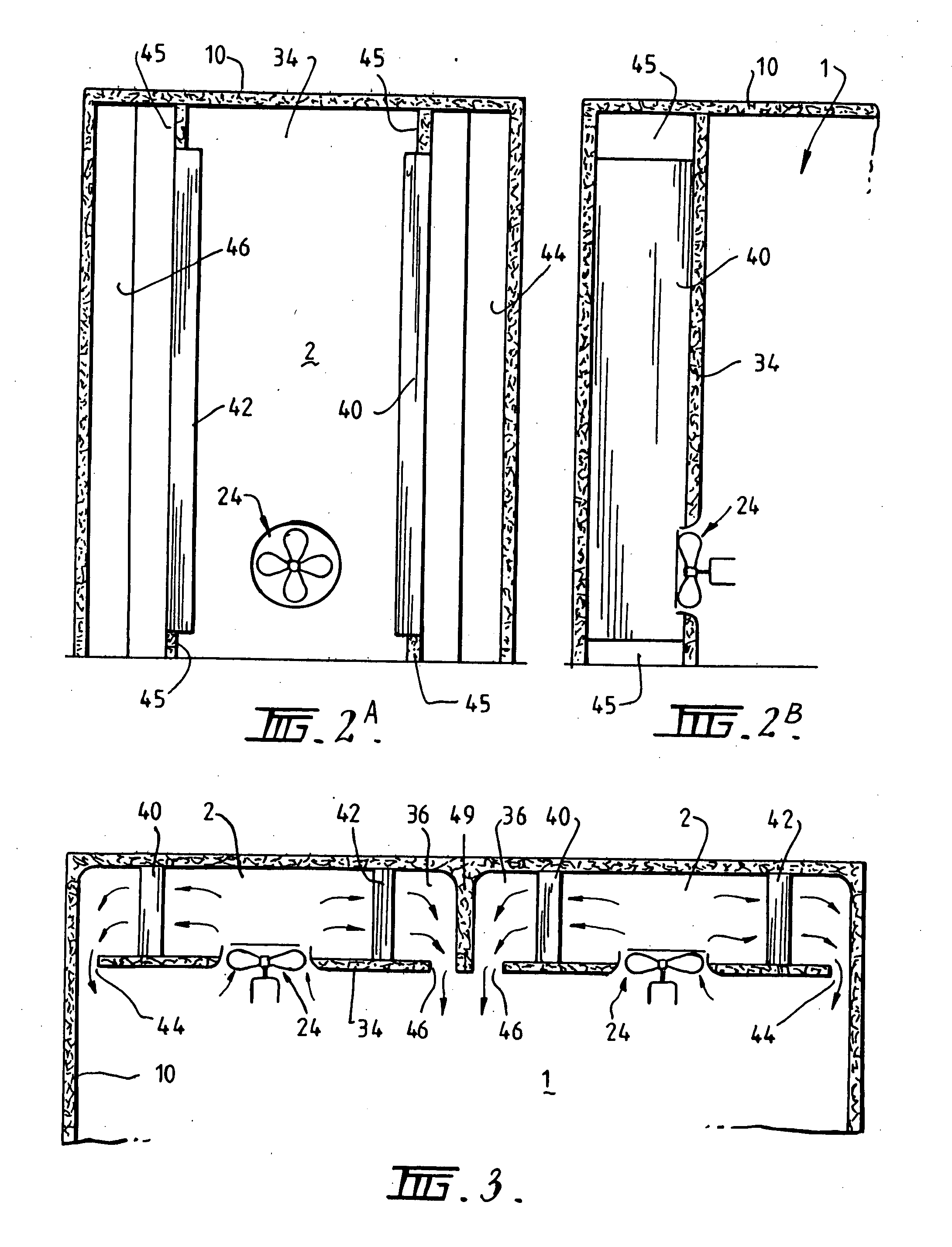

[0049]Referring firstly to FIG. 1A, the invention can be seen to comprise an integrated air flow control facility for forced cooling of produce stored in a cool room 10. The air flow control facility is preferably integrated into the construction of the cool room 10 and comprises discrete and dedicated zones including a storage zone 1 for the storage of produce for cooling where the storage zone 1 generally forms the bulk of the cooling room. The air flow control facility also includes a dedicated and discrete refrigeration zone 2 formed as part of the cool room 10 but specifically separated from the storage zone 1 by virtue of a physical divider 34. The physical divider 34 is provided with one or more integral extraction fans 24 so as to provide for the drawing of air from the storage zone 1 into the refrigeration zone 2 for subsequent passage past refrigeration coil means 40 and 42 positioned within the refrigeration zone 2. The divider 34 further includes one or more outlets 44 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com