Incorporated slide fastener

A zipper and weaving technology, which is applied in the field of weaving zippers, can solve the problems of weft thread cutting and inability to withstand long-term use, and achieve the effects of eliminating deviation, improving softness, and reducing the number of lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

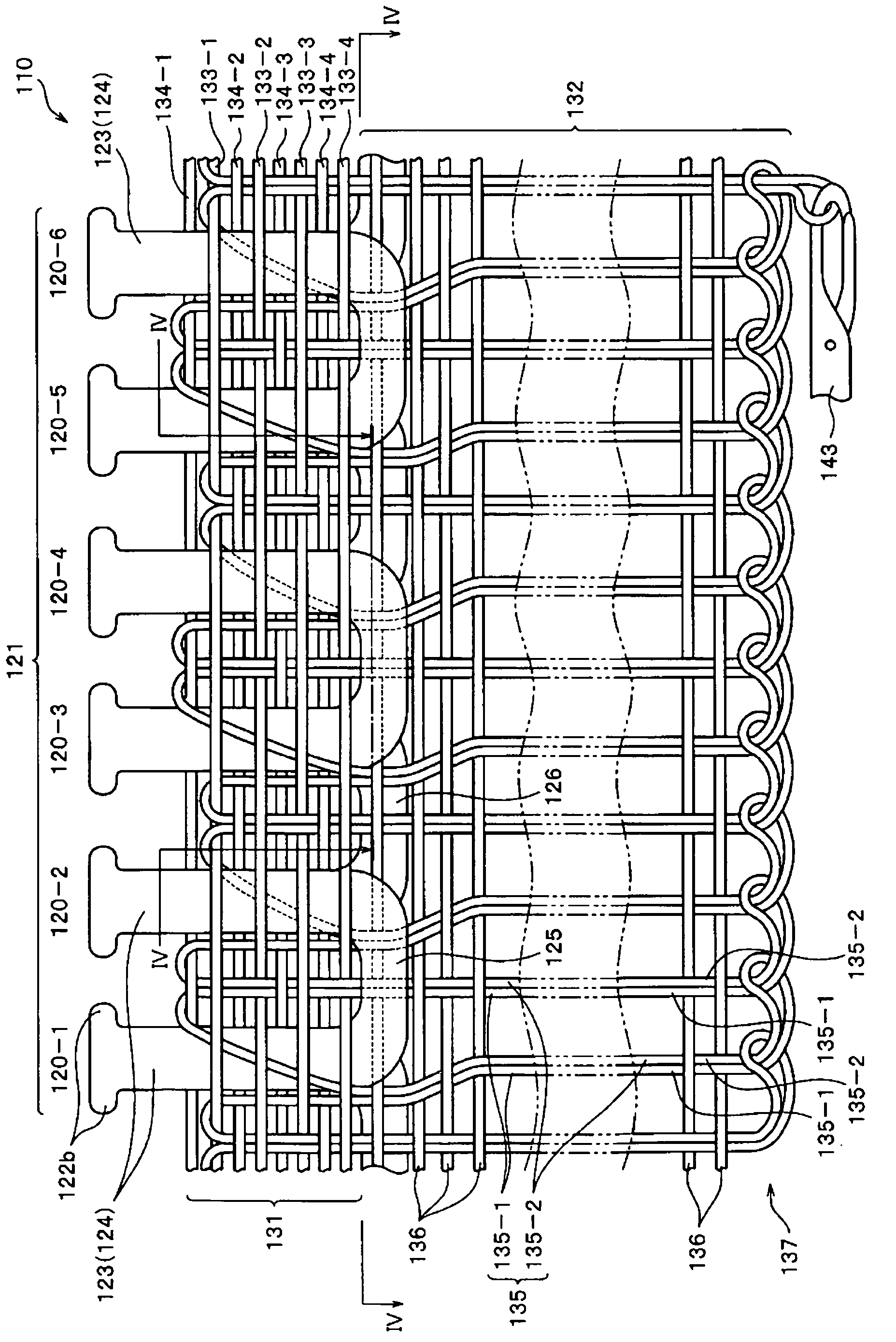

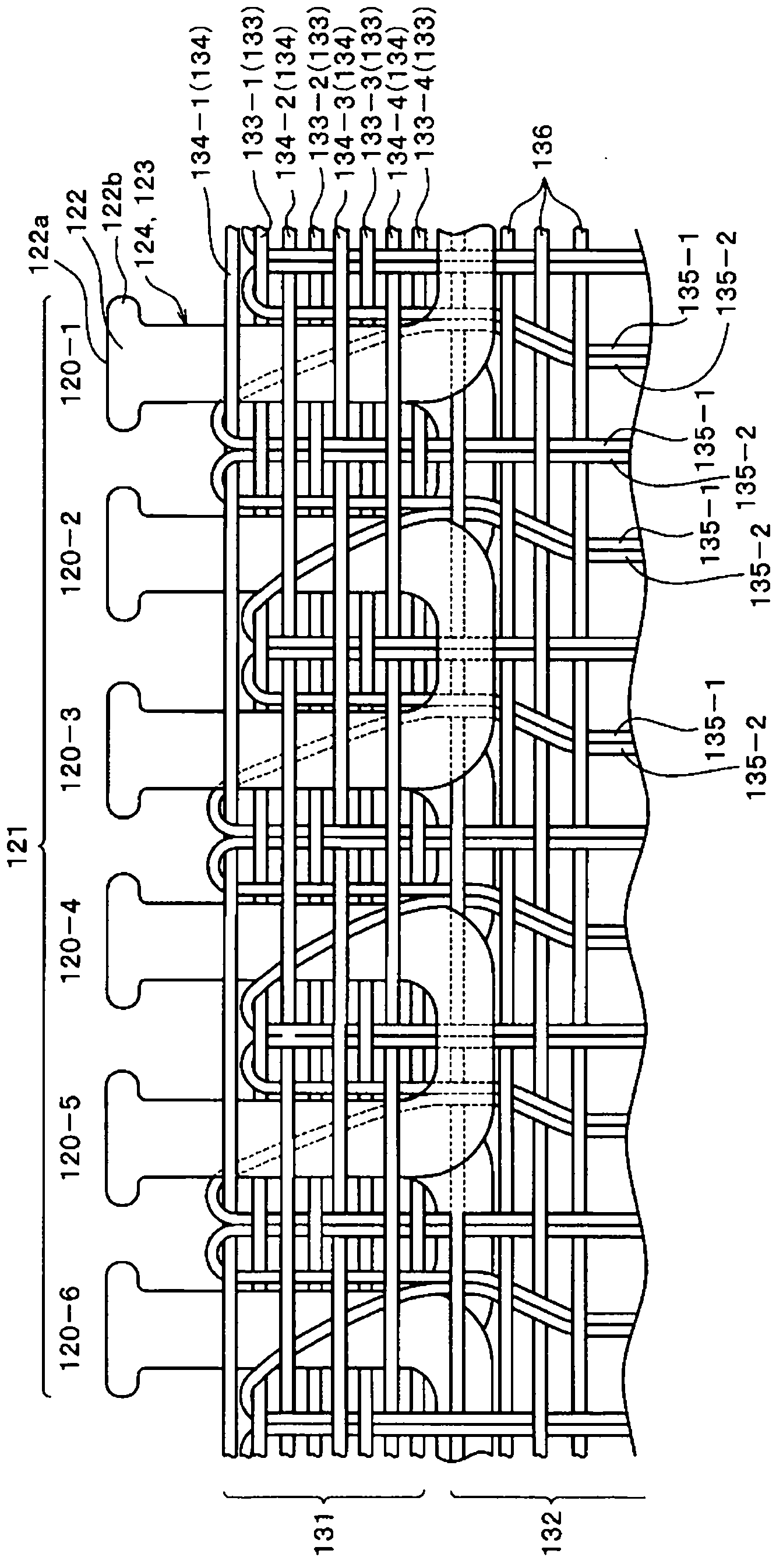

[0024] Below, while referring to the attached Figure 1 Typical embodiments of the present invention will be described in detail. In addition, the present invention is not limited to the illustrated embodiment, and various modifications are possible as long as changes are made within substantially the same range. In addition, in weaving the fastener tape described below, a case will be described in which a knitting machine that beats up a weft yarn held by a tip end of a needle is used by inserting it into an opening of the warp yarn.

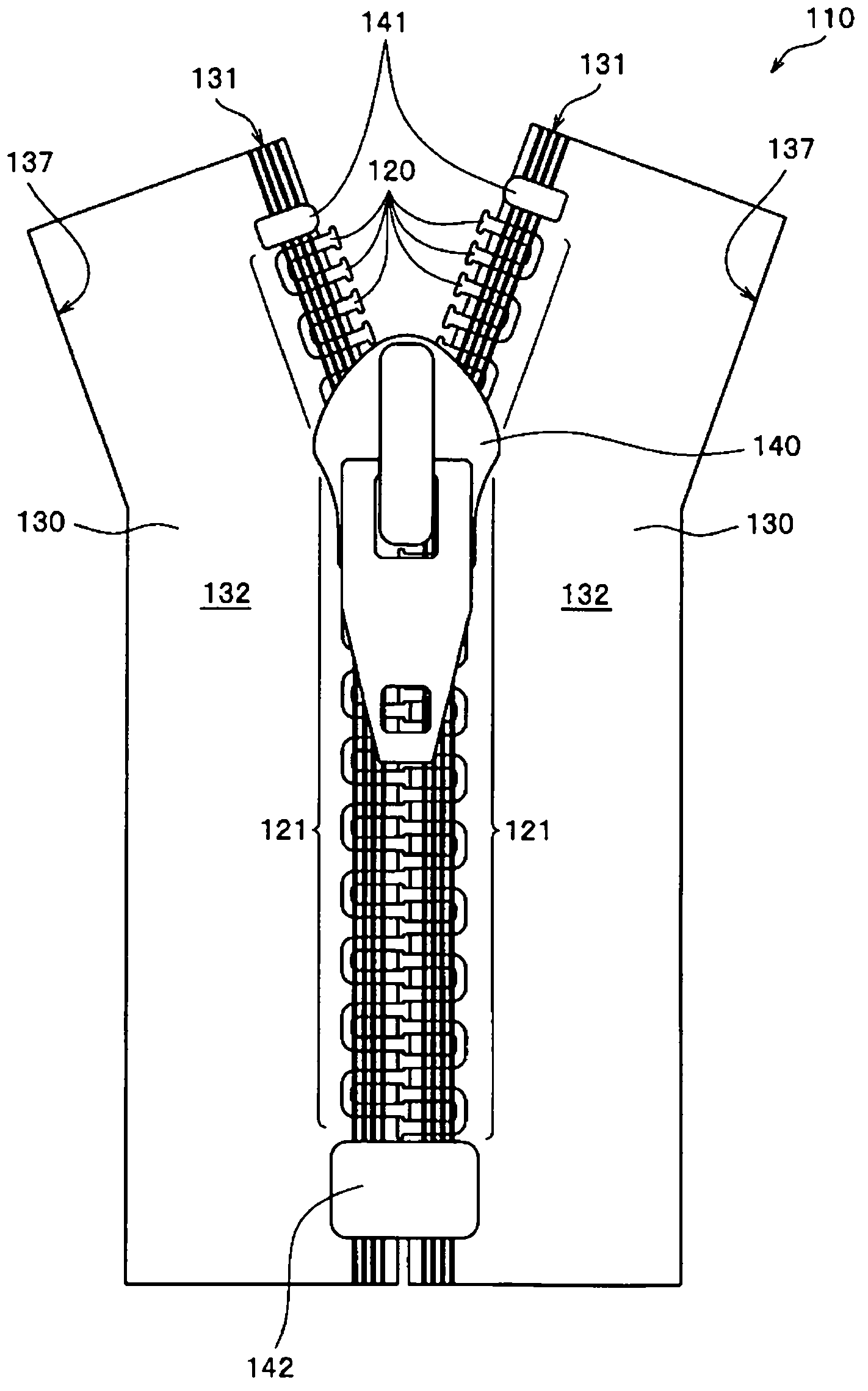

[0025] Figure 1 ~ Figure 4 The main part of the slide fastener 110 in which the zigzag-shaped continuous fastener element 120 of 1st Embodiment of this invention was woven into the fastener tape 130 is shown. The zipper tape 130 has: a tooth mounting portion 131 for mounting a zigzag continuous tooth row 121 in which a plurality of zipper teeth 120 are continuously formed along one edge portion in the width direction of the tape; and a tape ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com