Disposable, biodegradable, insole sock

a biodegradable, insole technology, applied in the direction of uppers, boots, insoles, etc., can solve the problems of not meeting environmental concerns, unable to meet environmental concerns, and unable to manufacture products made of nonwoven materials or felt, and not having the cost advantage of cellulose or plant based materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

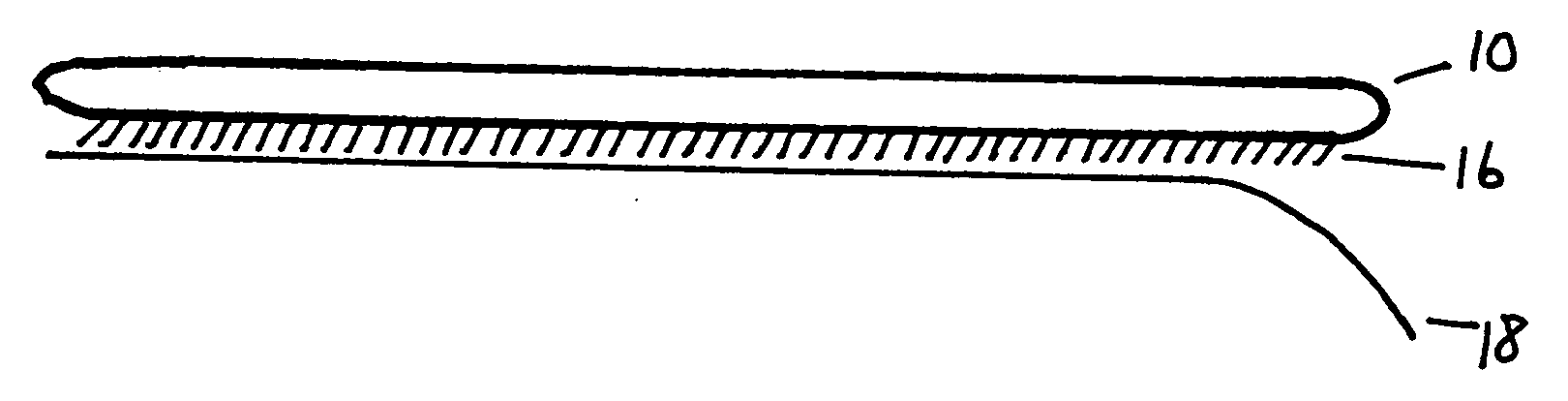

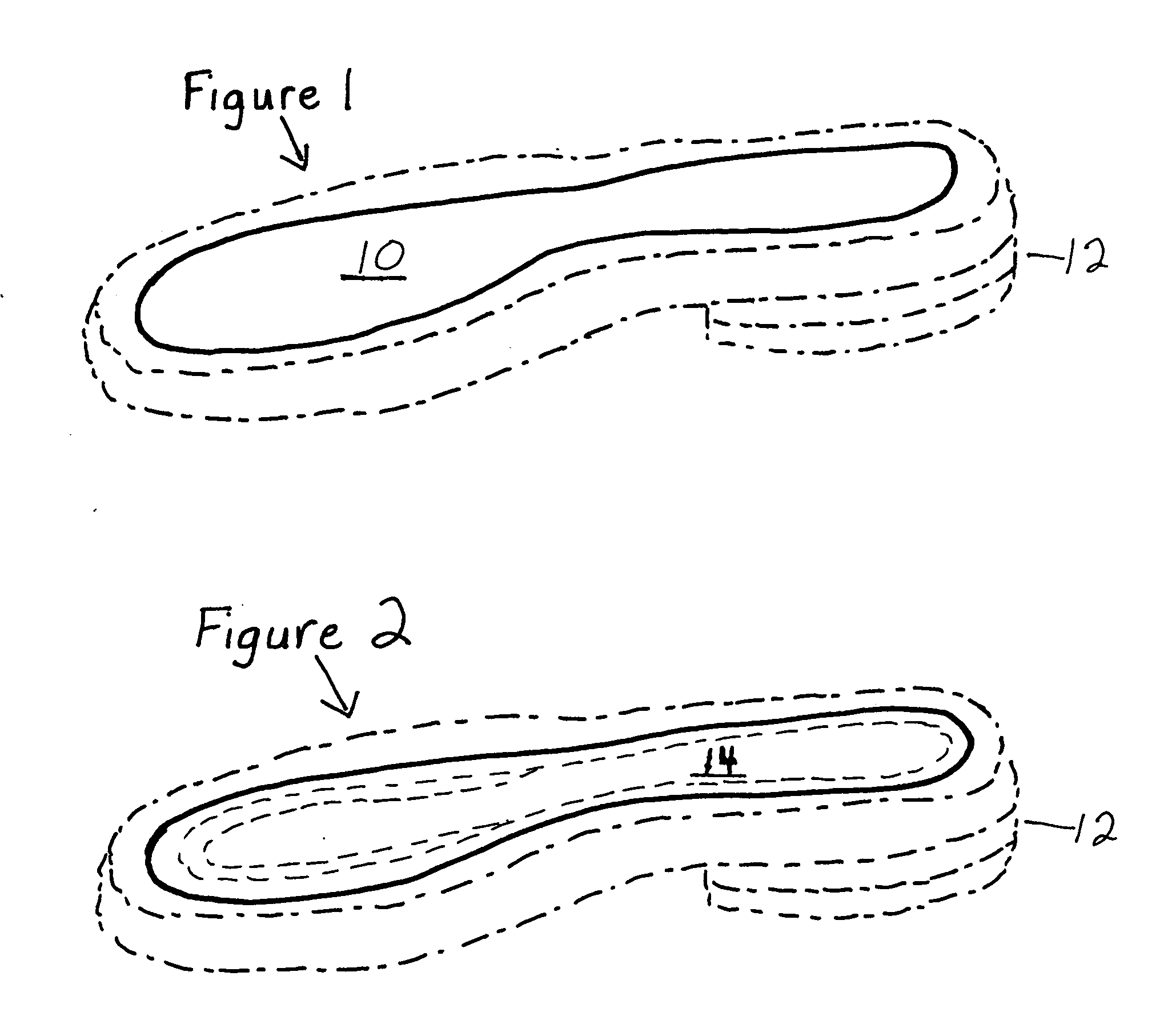

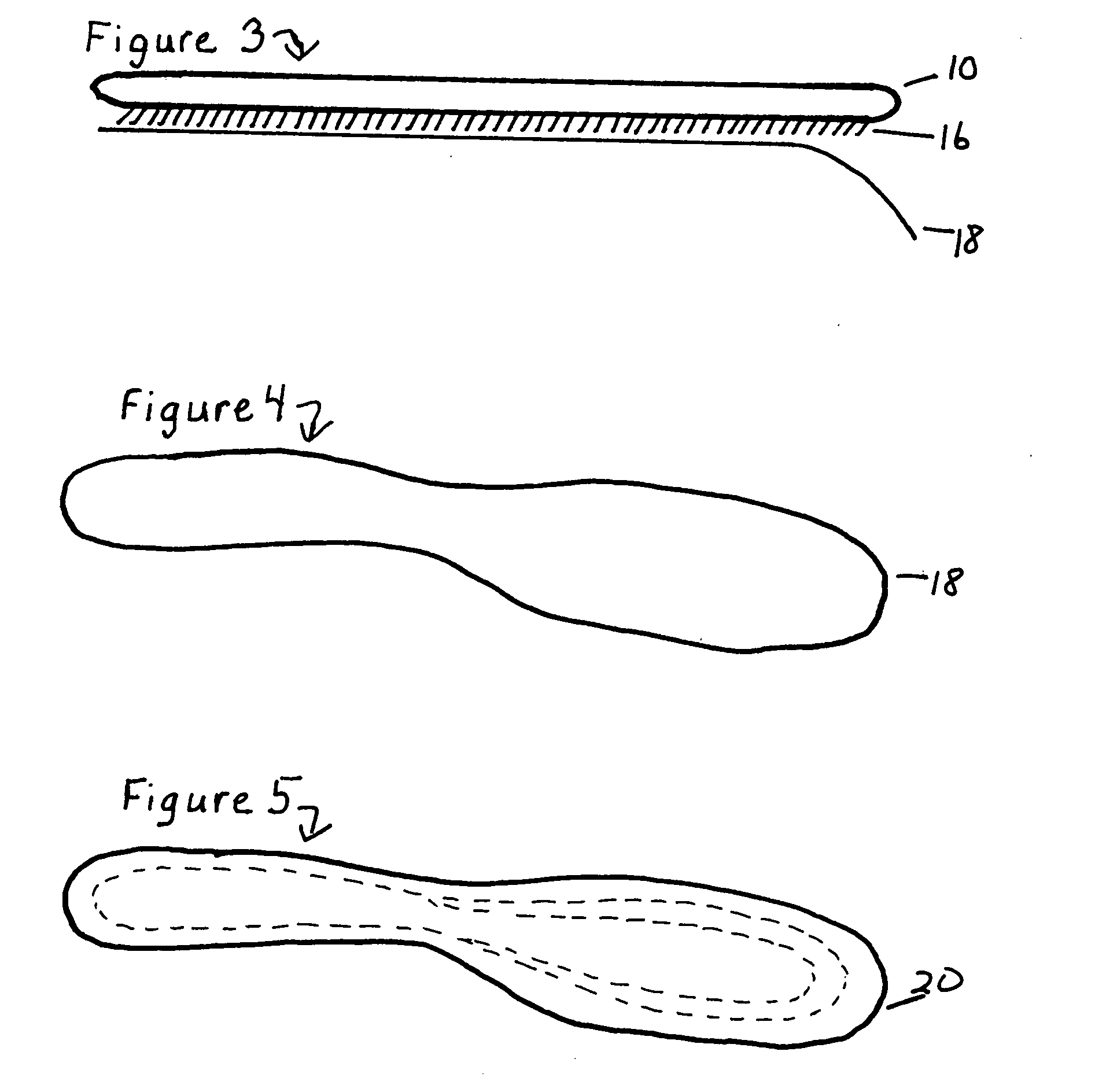

[0030]The Disposable Insole Sock 10 is made by either cutting soft, durable, absorbent paper in the shape of an insole or by casting. The cutting may be done by hand held scissors or by a die cutting machine. The adhesive 16 may be sprayed on or applied by machine to the soft, durable, absorbent paper 10 before a protective paper 18 is added and before the insole socks are cut.

[0031]Ellmer's Craft Bond Multi-Purpose spray Adhesive serves as a temporary bond. Saturation paper S-20 sold by Buckeye Technologies in Memphis, Tenn. is an example of a soft absorbent paper.

[0032]The physical structure is shown in FIGS. 1 and 3. Soft, durable, absorbent paper is cut in the shape of shoe insole 10. One side will have a light adhesive 16 on it to stick enough to be held in place and yet be removed easily. It will be sold with a throw away paper backing 18, protecting the adhesive side of the Disposable Insole Sock.

[0033]The ability of paper to be printed with or dyed to different colors and de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com