Epoxy Resin Composition for Optical-Semiconductor Encapsulation, Cured Resin Thereof, and Optical Semiconductor Device Obtained with the same

a technology of semiconductor devices and encapsulation, which is applied in the direction of semiconductor/solid-state device details, solid-state devices, organic dyes, etc., can solve the problems of colorant disadvantageously changing the optical property of shielding near infrared rays, low shielding ability of glass, and insufficient use in illuminance sensors. , to achieve the effect of reducing or eliminating the property of shielding, preventing optical properties, and changing the optical properties of colorants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples 1 to 3

[0078] A phthalocyanine colorant and naphthalocyanine colorants were added in the amounts shown in Table 1 below to a mixture composed of 100 parts of an epoxy resin, 99 parts of a curing agent, and 1 part of a curing accelerator as shown in the table.

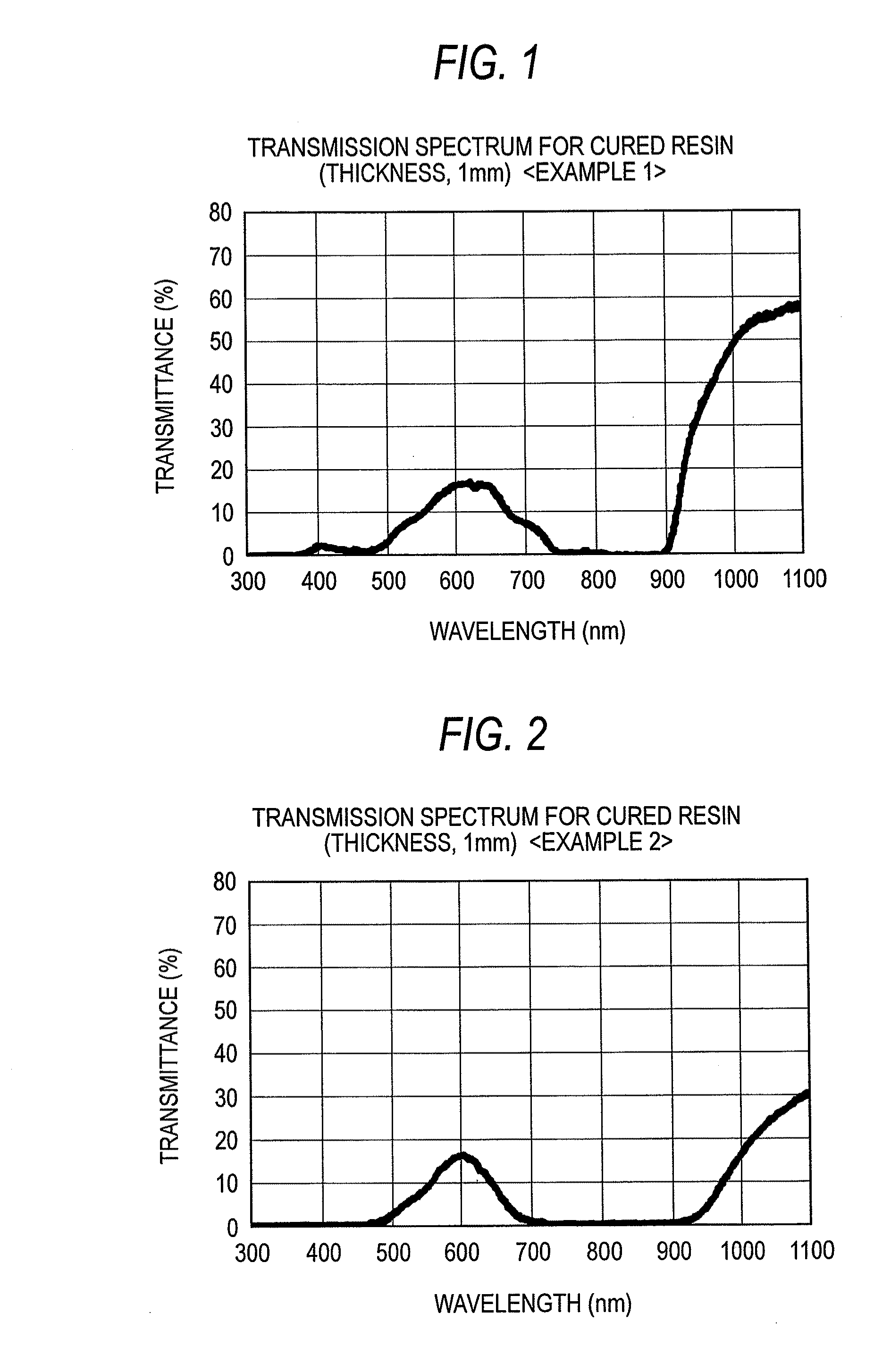

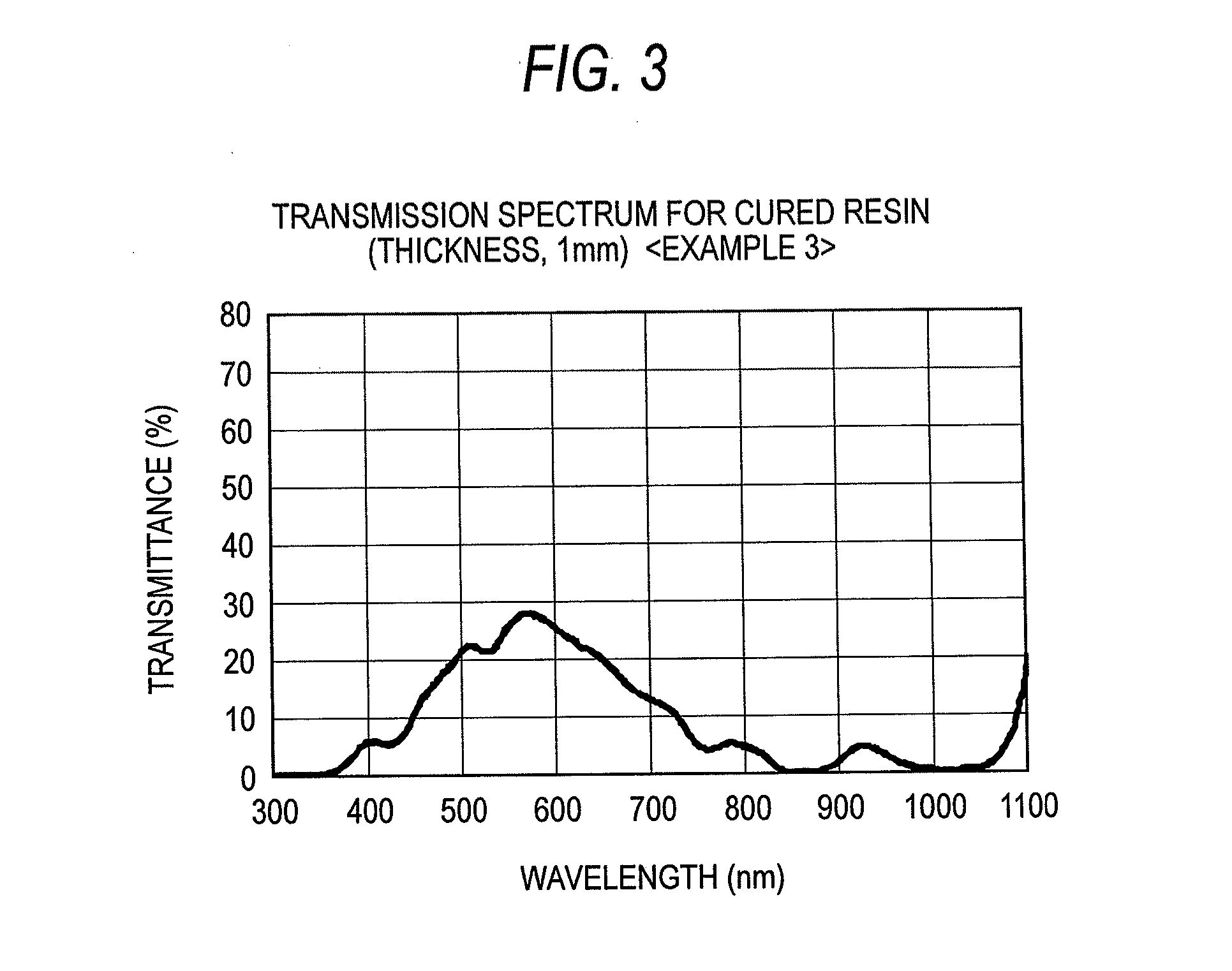

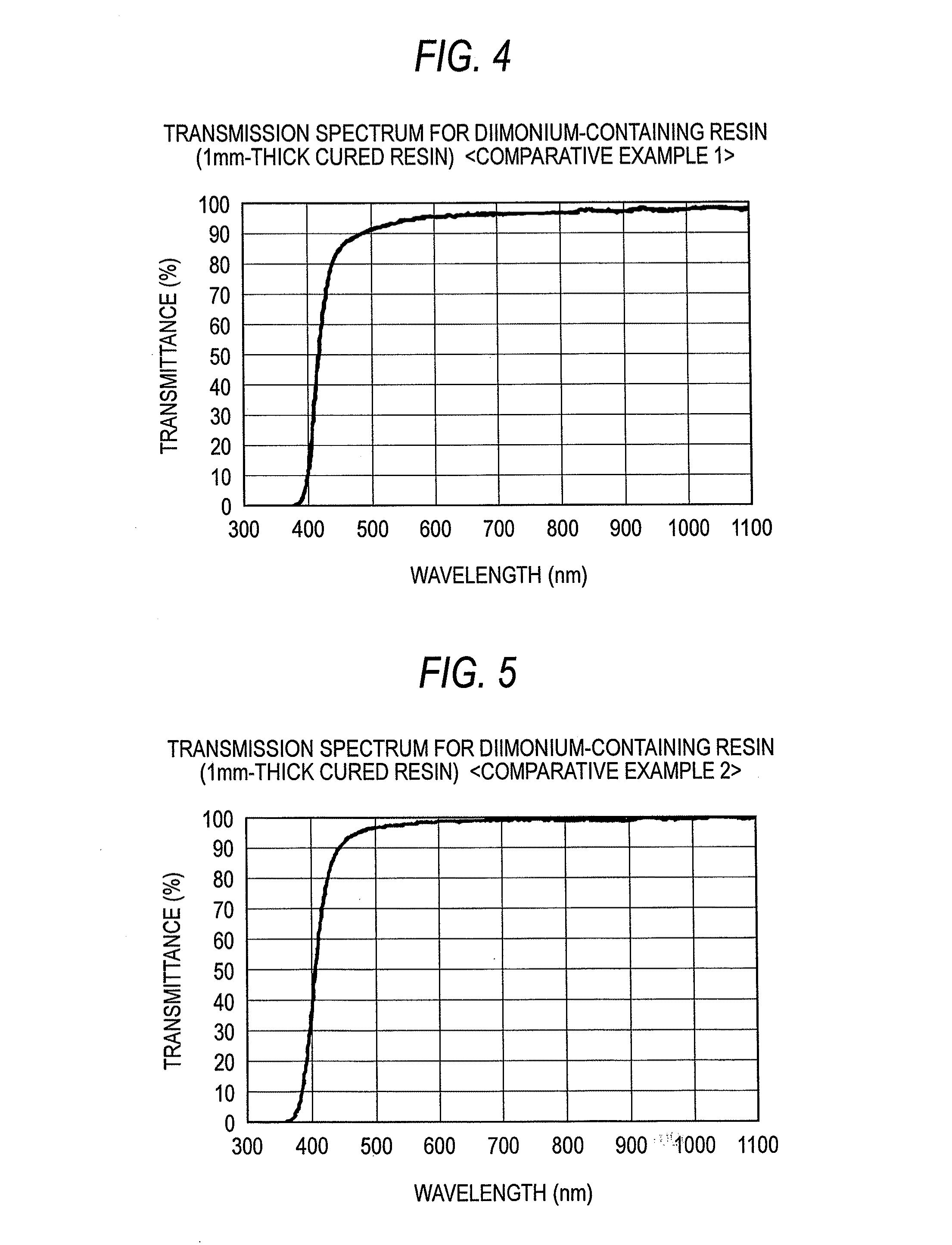

[0079] Each liquid resin composition obtained (epoxy resin composition for optical-semiconductor encapsulation) was poured into a mold having a thickness of 1 mm and heated at 150° C. for 3 hours to obtain a cured resin composition. This cured resin composition (1-mm thick) was examined with apparatus UV-3101PC (manufactured by Shimadzu Corp.) for a transmission spectrum. The results obtained are shown in FIG. 1 (Example 1), FIG. 2 (Example 2), and FIG. 3 (Example 3). As apparent from FIGS. 1 to 3, the cured resins obtained in Examples 1 to 3 had a transmittance in the near infrared region (750 to 900 nm) of 5% or lower.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength range | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

| wavelengths | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com