Respirator mask

a mask and respirator technology, applied in the field of masks, can solve the problems of patient discomfort, masks that do not fit properly, and impaired patient's vision,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

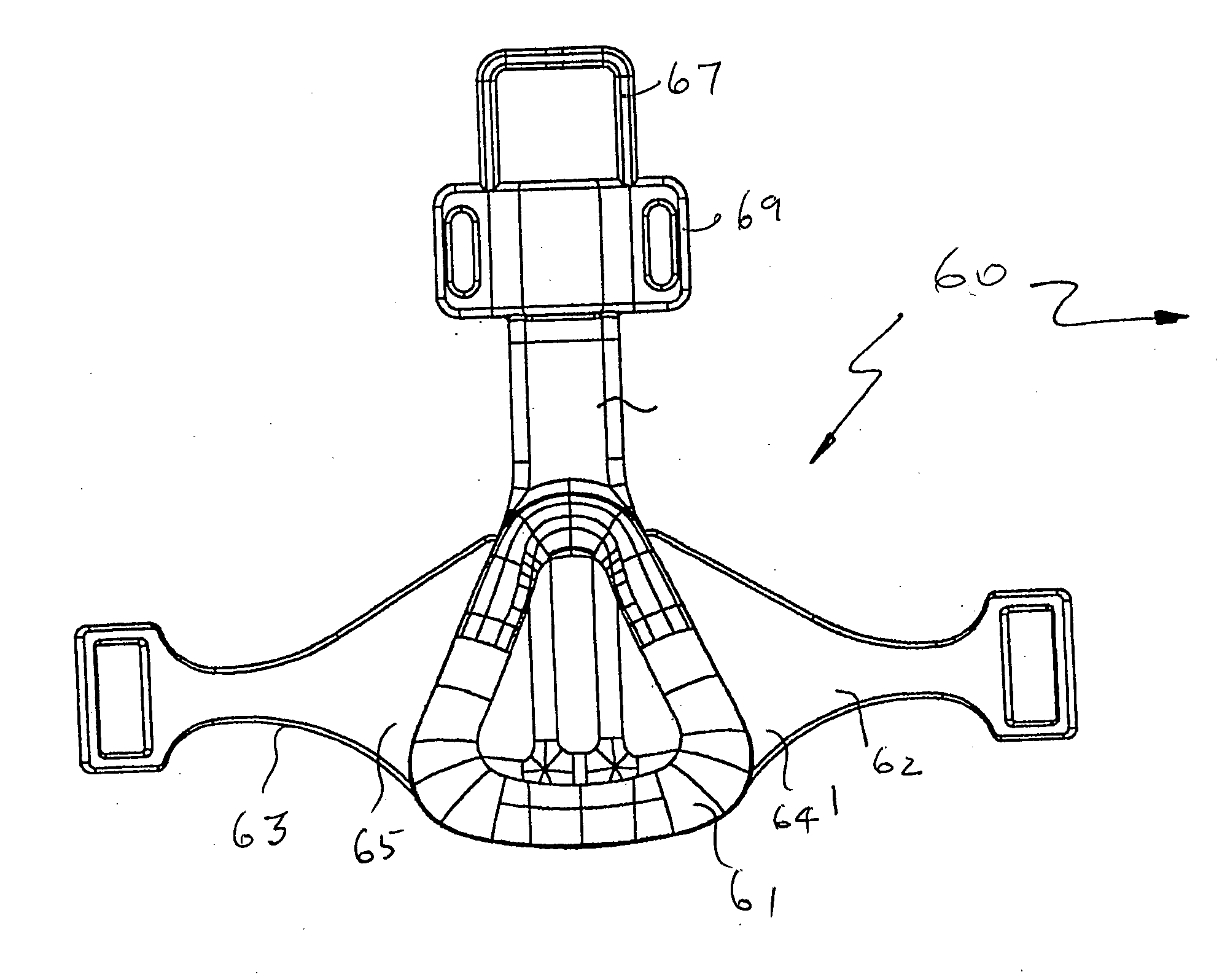

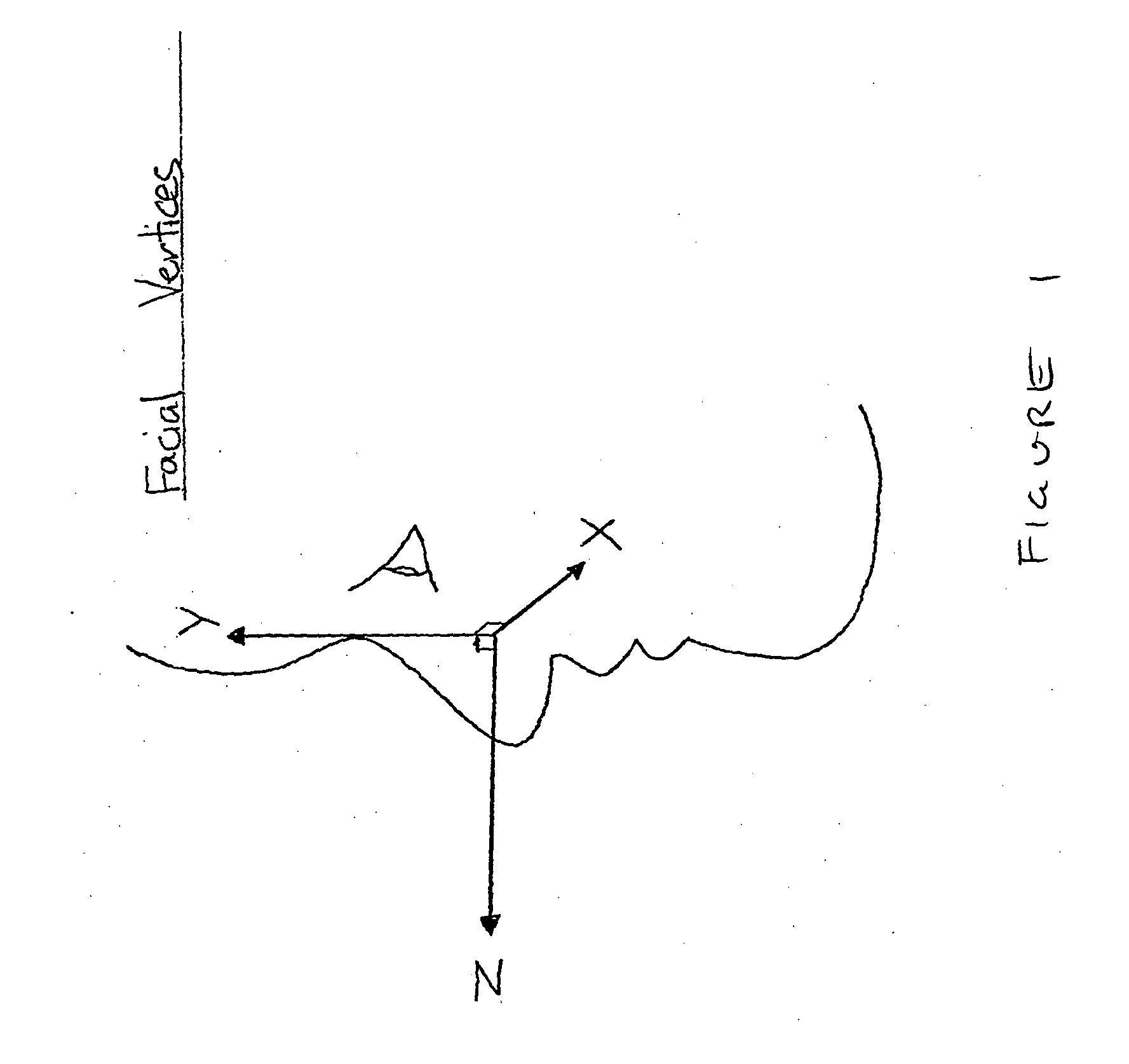

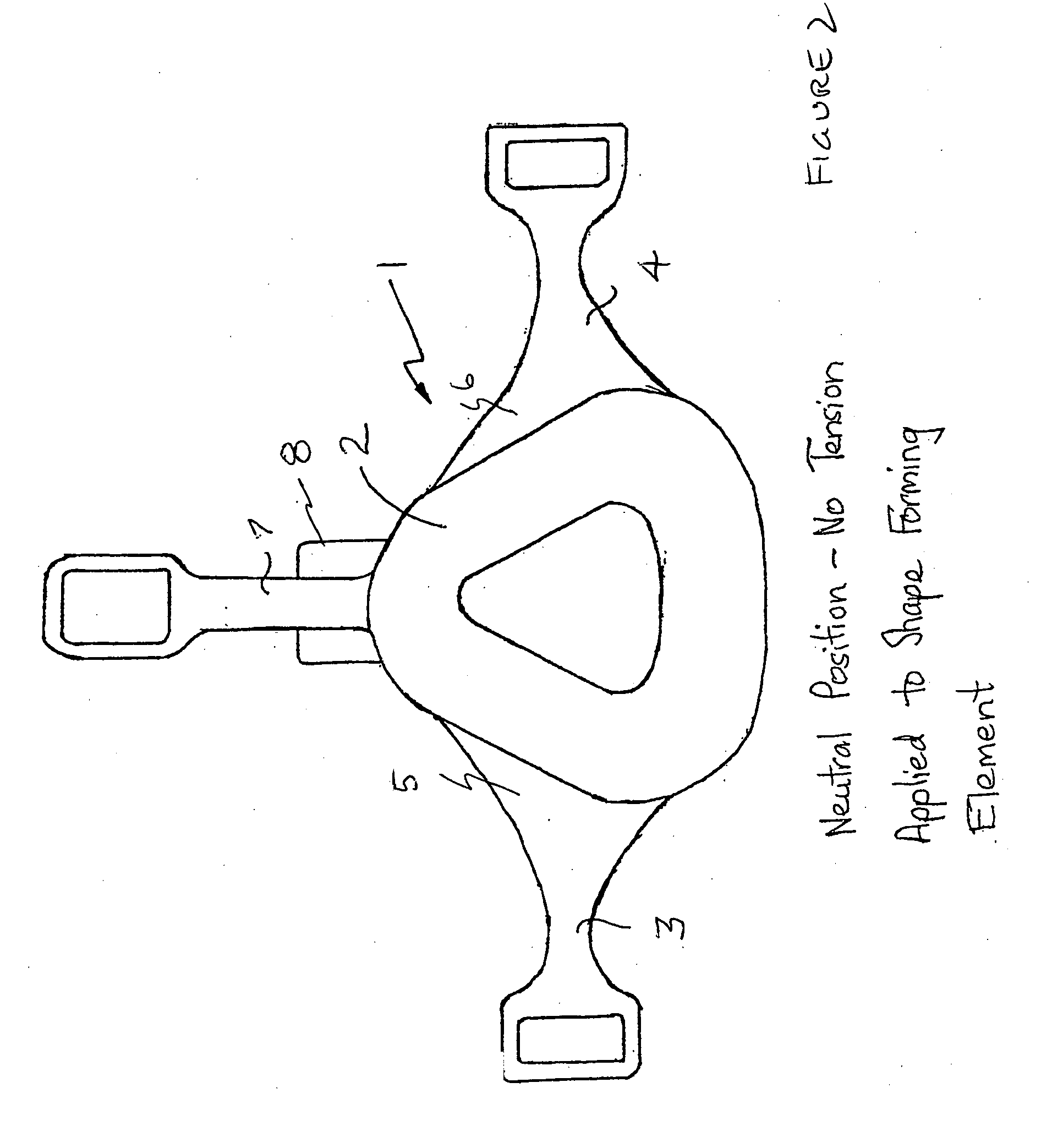

[0151]Referring to the drawings, FIG. 1 shows a schematic view of a face indicating the X, Y and Z axes. FIGS. 2 to 10 schematically illustrate a first embodiment of a mask 1 and the principles governing the design and operation of that mask in response to the use of an enlarged web contact portion. FIG. 2 shows a back side elevation of the mask 1. Mask 1 includes a flexible face contacting element 2 and straps 3 and 4. Each of straps 3 and 4 respectively include enlarged web portions 5 and 6 which transfer loads from the straps to the manifold. Mask 1 has been moulded in a single piece from a flexible elastomeric material, most preferably a medical grade silicone. However, any suitable elastomeric material may be used. Mask 1 further includes a third strap 7 and an air inlet 8 . The mask of FIG. 1 is shown in a configuration without applied loads. FIG. 3 shows the mask 1 of FIG. 1 with corresponding numbering. The mask in FIG. 3 is shown with straps under a load creating a distorti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com