Oil return algorithm for capacity modulated compressor

a compressor and capacity technology, applied in the direction of machines/engines, liquid fuel engines, lighting and heating apparatus, etc., can solve the problems of insufficient supply of lubricant back to the compressor, difficult to adequately drive lubricant back, and too often operation, etc., to achieve the effect of increasing the compressor capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

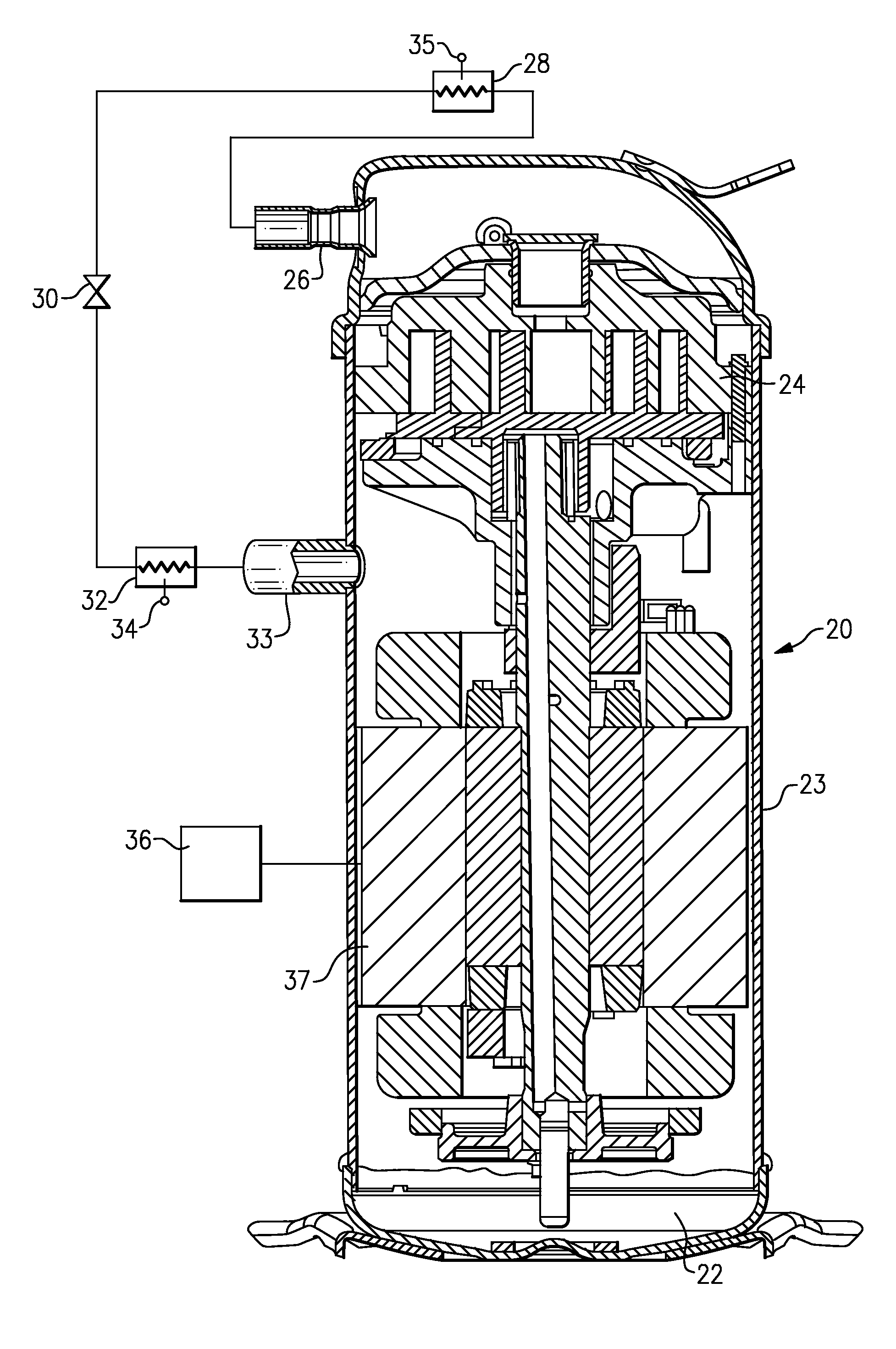

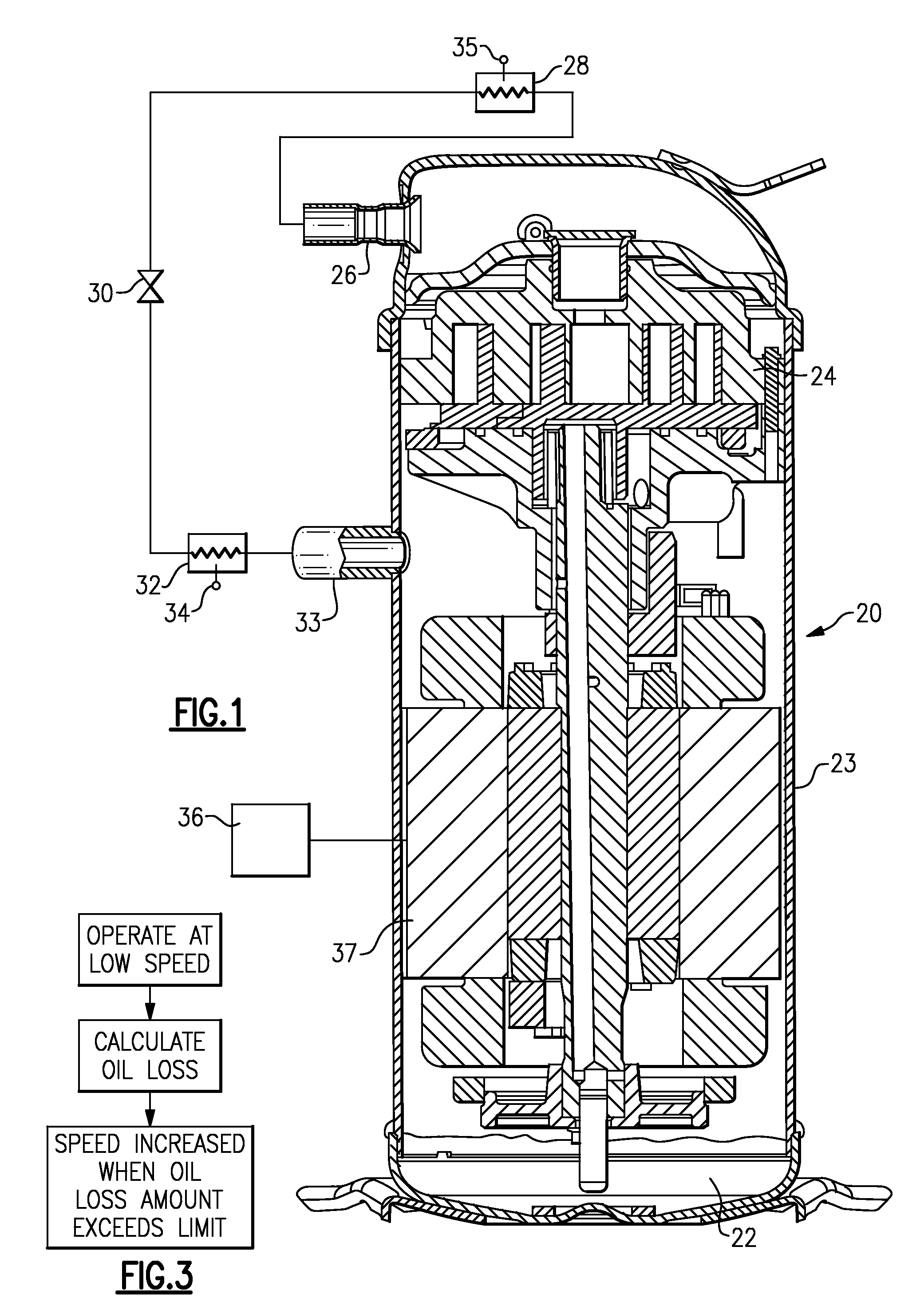

[0011]A refrigerant system 20 is illustrated in FIG. 1. A compressor shell 23 includes a lubricant sump 22, which maintains a quantity of lubricant. A compressor pump unit 24 compresses refrigerant and delivers the refrigerant to a discharge tube 26. From the discharge tube 26, the lubricant passes through a condenser 28, an expansion device 30, an evaporator 32, and back through a suction tube 33 into the compressor shell 23.

[0012]A control 36 for a compressor motor 37 may operate the compressor motor 37 at various speeds. Thus, the compressor may be operating at a relatively low speed to increase energy efficiency when a cooling demand is also low.

[0013]Sensors 34 and 35 monitor a condition, such as pressure, at the evaporator 32 and condenser 28, respectively. Alternatively, sensors that monitor temperature or an estimated saturated refrigerant temperature can be used to detect the conditions the compressor is operating at, These conditions may be sent to the control 36 to assist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com