Heat dissipation device with fan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

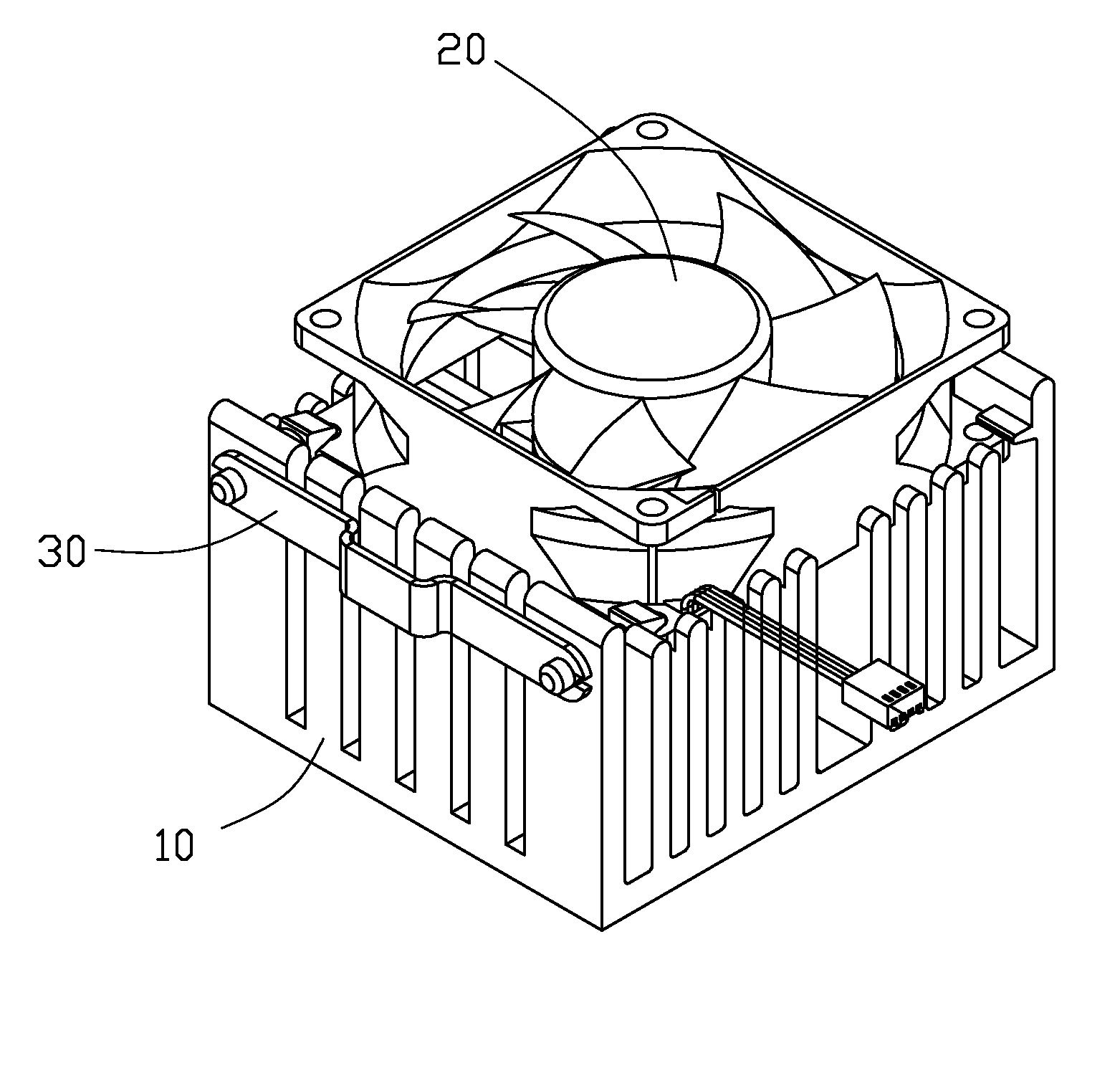

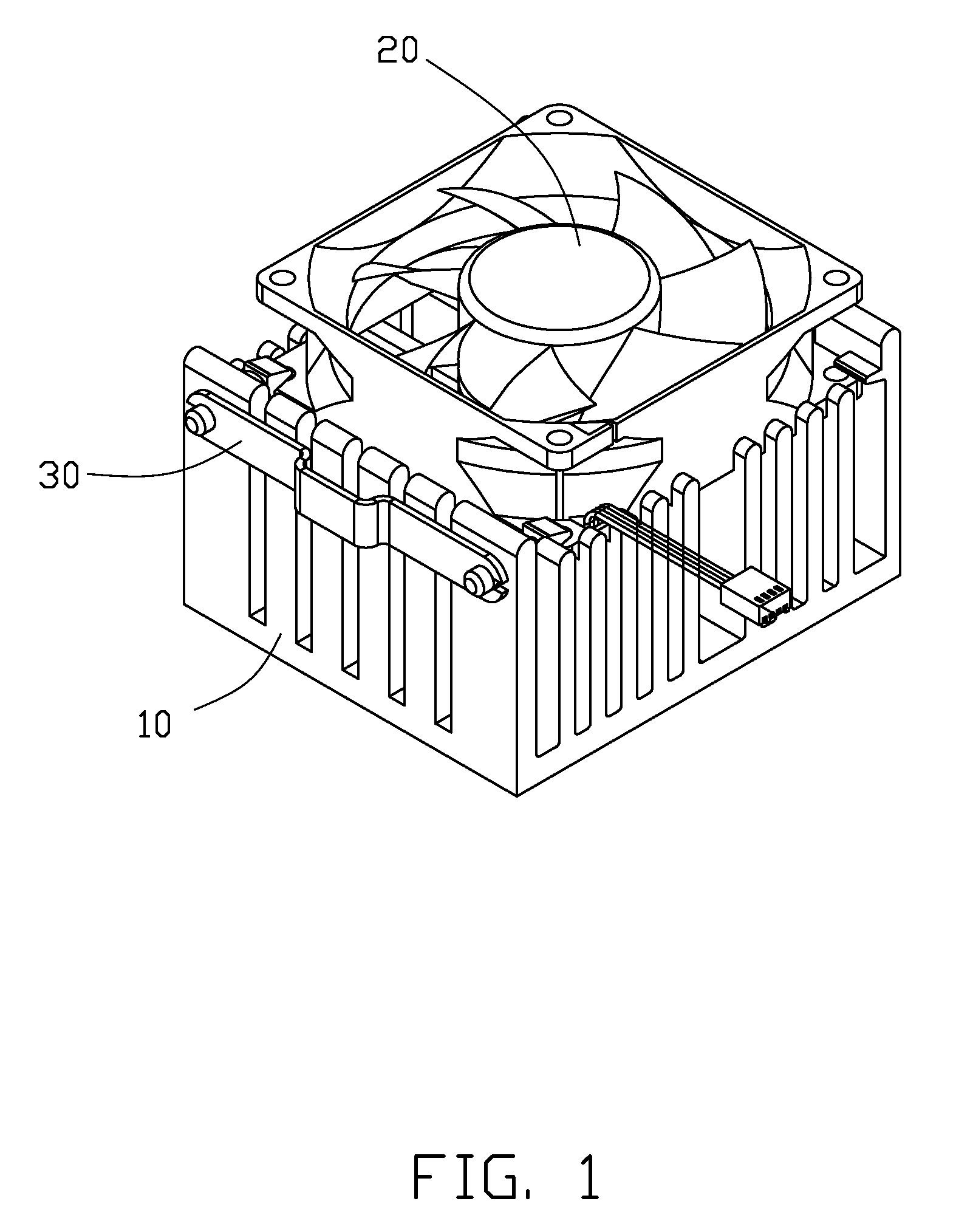

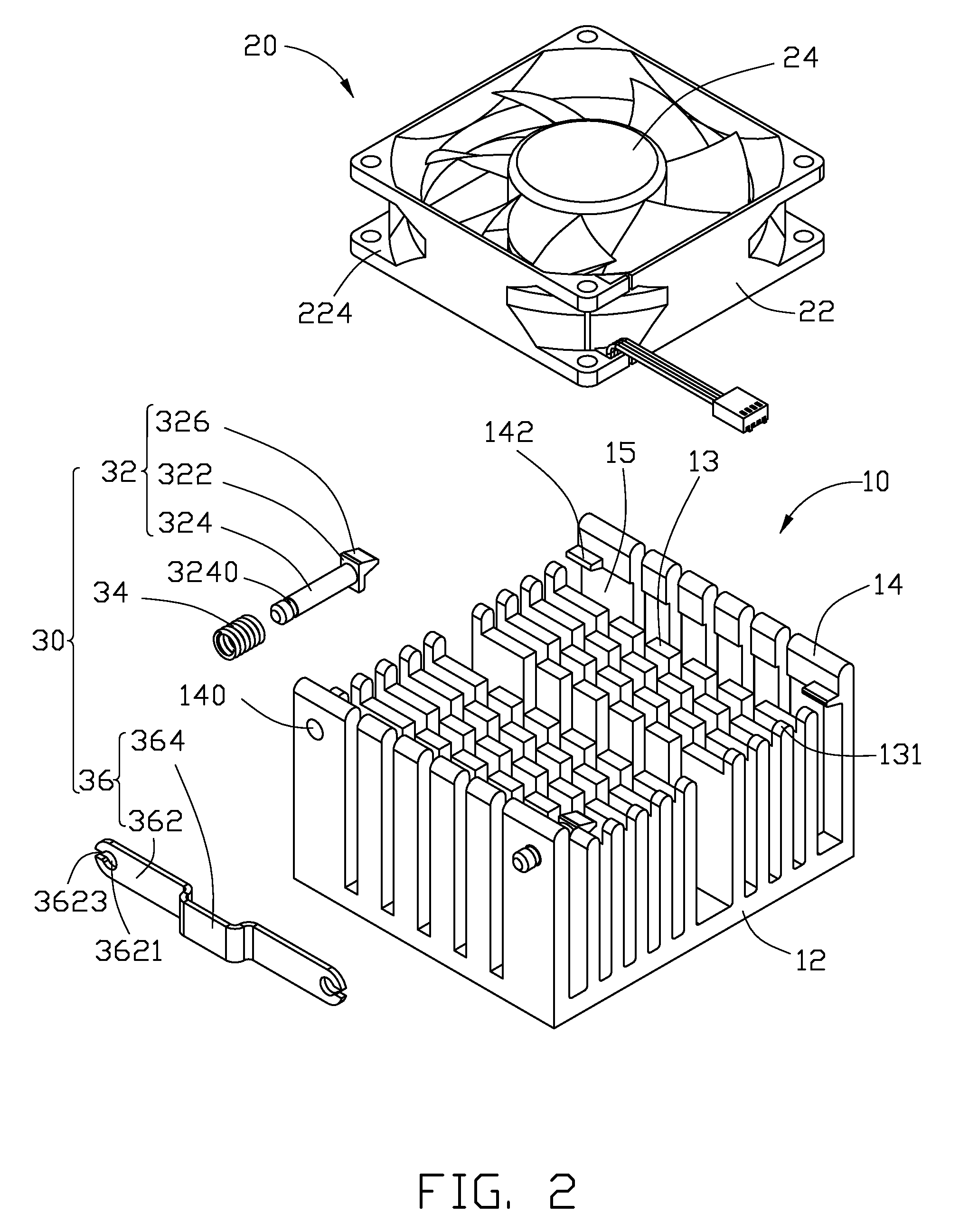

[0012]Referring to FIG. 1, an embodiment of a heat dissipation device comprises a heat sink 10, a fan 20 mounted on a top side of the heat sink 10 and an engaging member 30 fixed on the heat sink 10 and pressing the fan 20.

[0013]Referring to FIG. 2, the heat sink 10 comprises a rectangular base 12, a number of first fins 13 and a number of second fins 14. The first and second fins 13, 14 extend upwardly from a top surface of the base 12 and are spaced from each other. The first fins 13 are located at a central portion of the base 12. The second fins 14 are divided into two rows along a width direction of the base 12. The two rows of the second fins 14 are located at lateral edges of the base 12 and sandwich the first fins 13 therebetween.

[0014]The first fins 13 are divided into a number of rows along a length direction and a width direction of the base 12. Each of the first fins 13 is elongated and perpendicularly connects with the base 12. Tops of the first fins 13 are coplanar and...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap