Battery assembly manufacturing method

a battery and assembly technology, applied in the direction of batteries, sustainable manufacturing/processing, wound/folded electrode electrodes, etc., to achieve the effect of uniform thickness, and reducing the spread of the thickness of the unit cell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

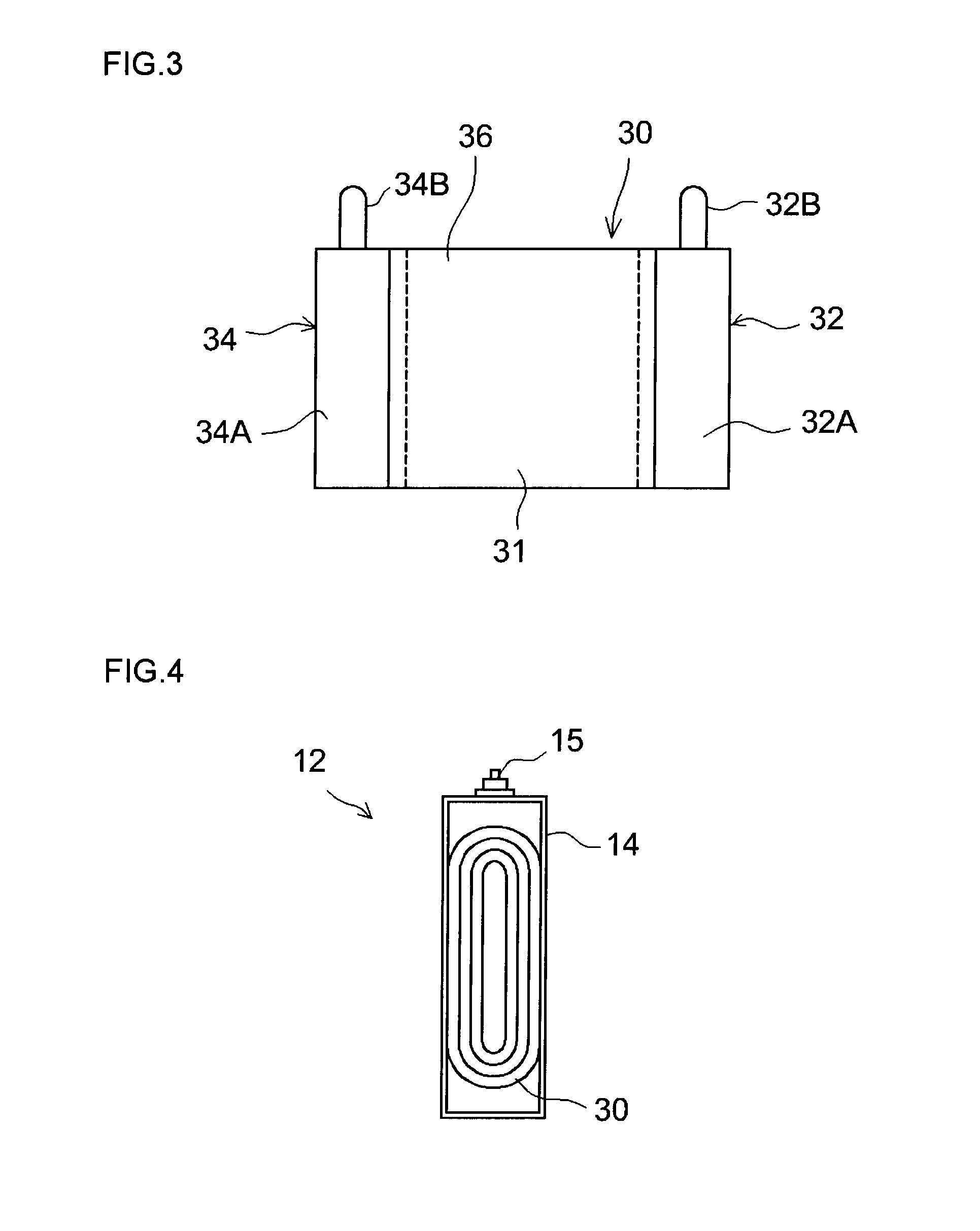

[0054]Similarly to a unit cell provided in the conventional battery assembly, a unit cell used as a constituent element of the battery assembly manufactured in each of the below-described embodiments typically includes an electrode body composed of predetermined constituent material of the battery (active materials of positive and negative electrodes, collectors of positive and negative electrodes, separator, etc.) and a container that accommodates the electrode body and an appropriate electrolyte.

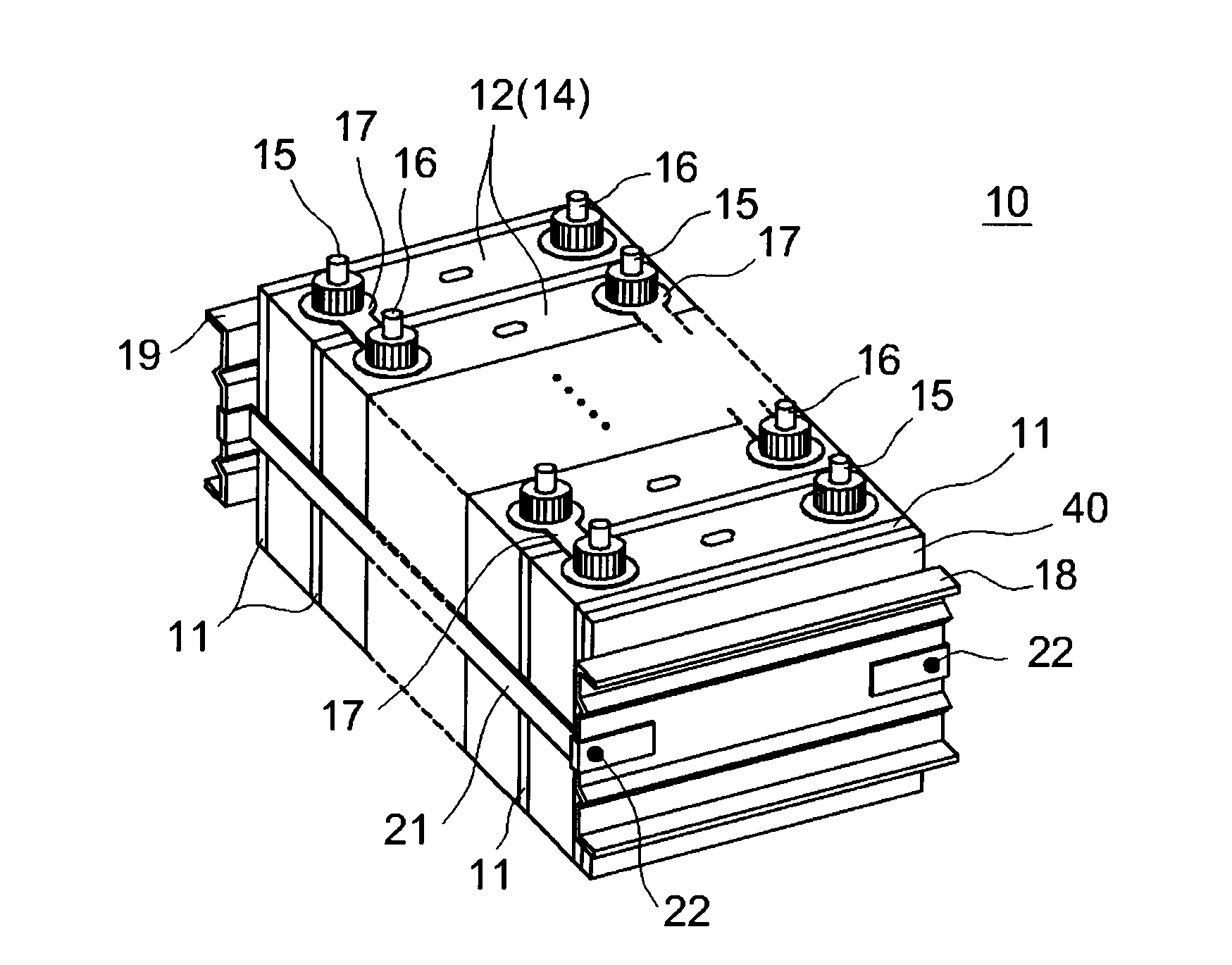

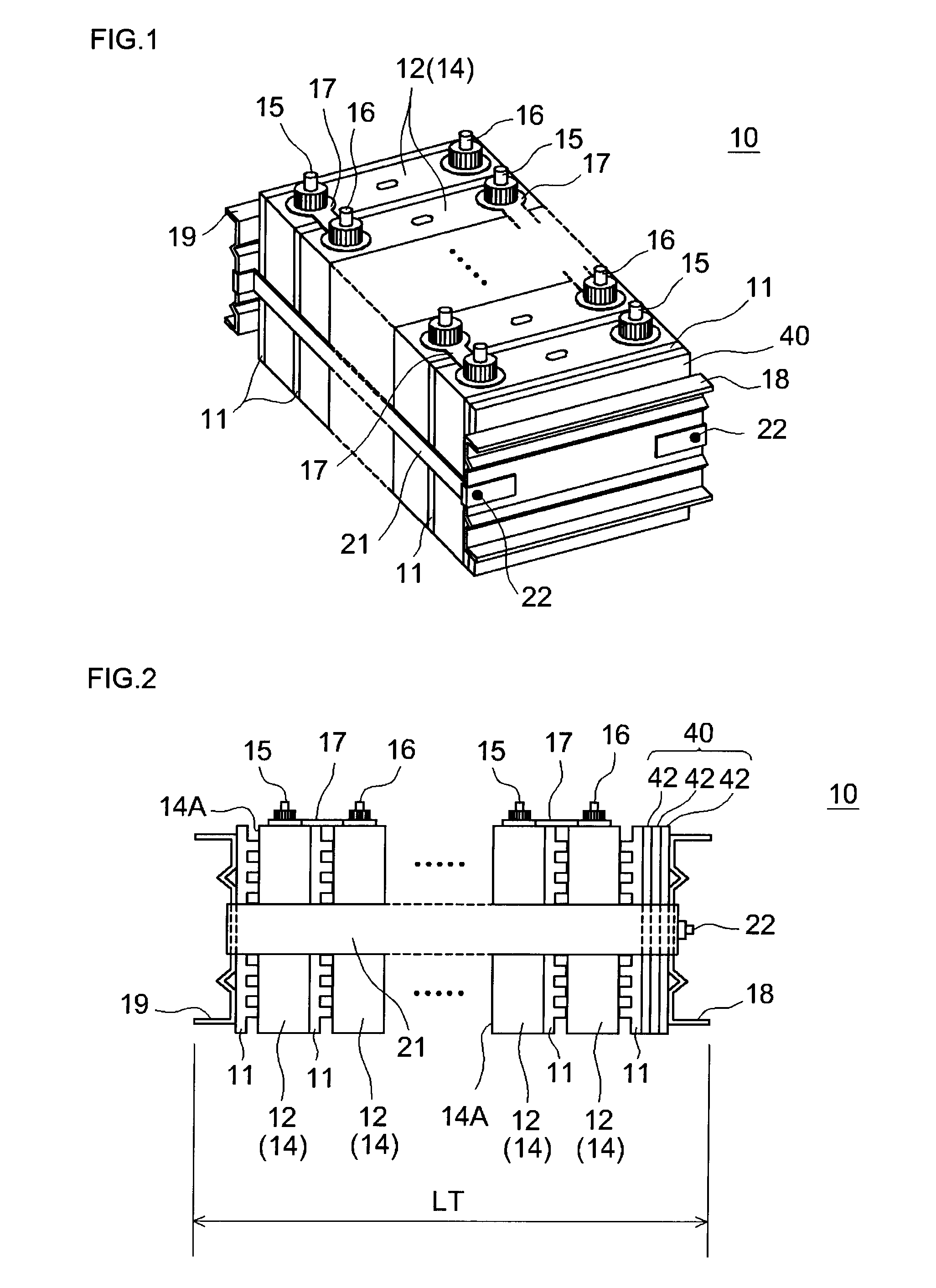

[0055]As an example, as shown in FIG. 1 and FIG. 2, a battery assembly 10 of the present example includes a predetermined number (typically 10 or more, preferably about 10 to 30, for example, 20) unit cells 12 of the same shape. The unit cell 12 has a container 14 of a shape (in the present embodiment, a flat box-like shape) that can accommodate the below-described flat-shaped wound electrode body. The “same shape” of the unit cells 12 means that the cells have been manufactured to the sam...

example 2

[0076]In the present embodiment, length adjusting means of a configuration different from that of the spacer member 40 in Example 1 is used as length adjusting means for converging the spread in stacking direction length L1 of the stacked body.

[0077]As shown schematically in FIG. 8, a battery assembly 10 of the present example includes a unit cell group composed of a predetermined number of unit cells 12 that have a structure similar to that described in Example 1 and cooling plates 11 disposed between the unit cells 12 and also at both outer sides in the stacking direction of the unit cells, end plates 50, 19 disposed in intimate contact with the cooling plates 11 arranged at both outer side of the unit cell group, and a bundling band 21 that bundles a body 20 to be bundled that is composed of the unit cell group and the end plates 50, 19 in the stacking direction. The battery assembly 10 is so configured that the body 20 to be bundled is bundled by the stipulated bundling pressure...

example 3

[0080]In the present embodiment, length adjusting means of a configuration different from that of the spacer member 40 in Example 1 is used as length adjusting means for converging the spread in stacking direction length L1 of the stacked body.

[0081]As shown schematically in FIG. 9, a battery assembly 10 of the present example includes a unit cell group composed of a predetermined number of unit cells 12 that have a structure similar to that described in Example 1 and cooling plates 11 disposed between the unit cells 12 and also at both outer sides in the stacking direction of the unit cells, a pair of end plates 18, 19 disposed further outside of the unit cell group, elastic members 62 disposed between the end plate 18 and the cooling plate 11 disposed on one outer side (right end in FIG. 9) of the unit cell group, and a bundling band 21 that bundles the aforementioned components (that is, a body 20 to be bundled that is composed of the unit cell group, end plates 18, 19, and elast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com