Hair Iron

a technology of hair iron and hair shaft, which is applied in the field of hair iron, can solve problems such as the damage of hair finishing, and achieve the effect of maintaining healthy hair

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026]Objects of regulating the surface of hair with the surfaces of correctors and dispersing force acting on cross sectional points of each hair that are in contact with the correctors are realized by making one of the correcting surfaces rougher than the other, to thereby increase contact points or contact areas that are in contact with the hair.

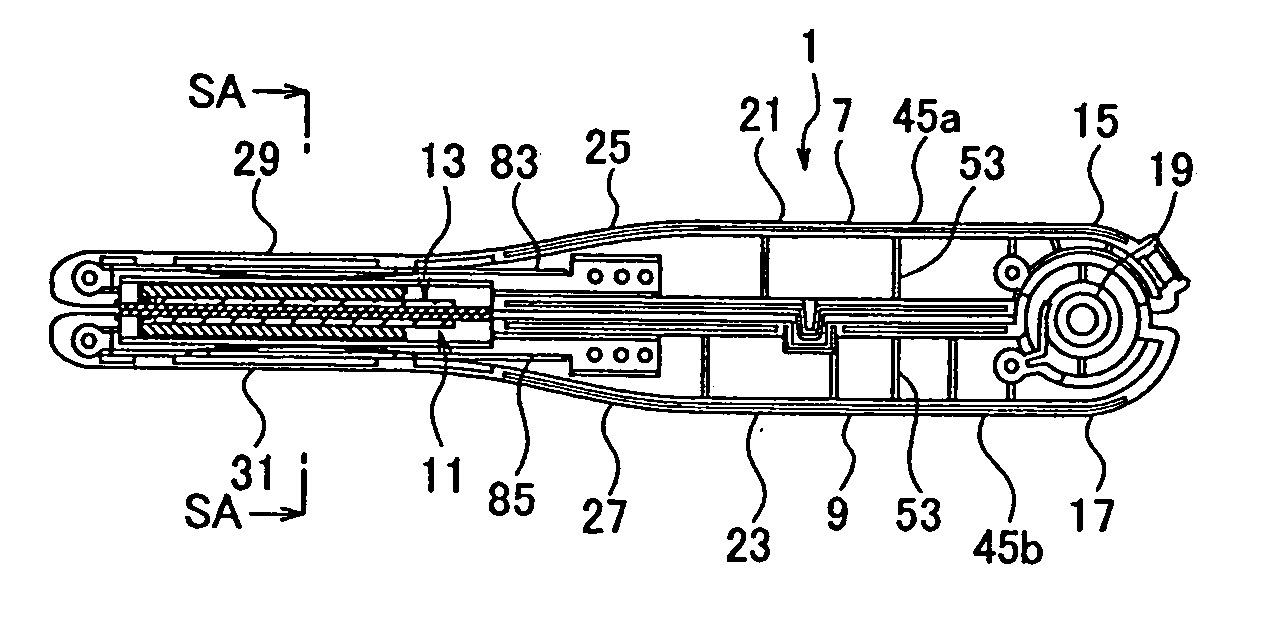

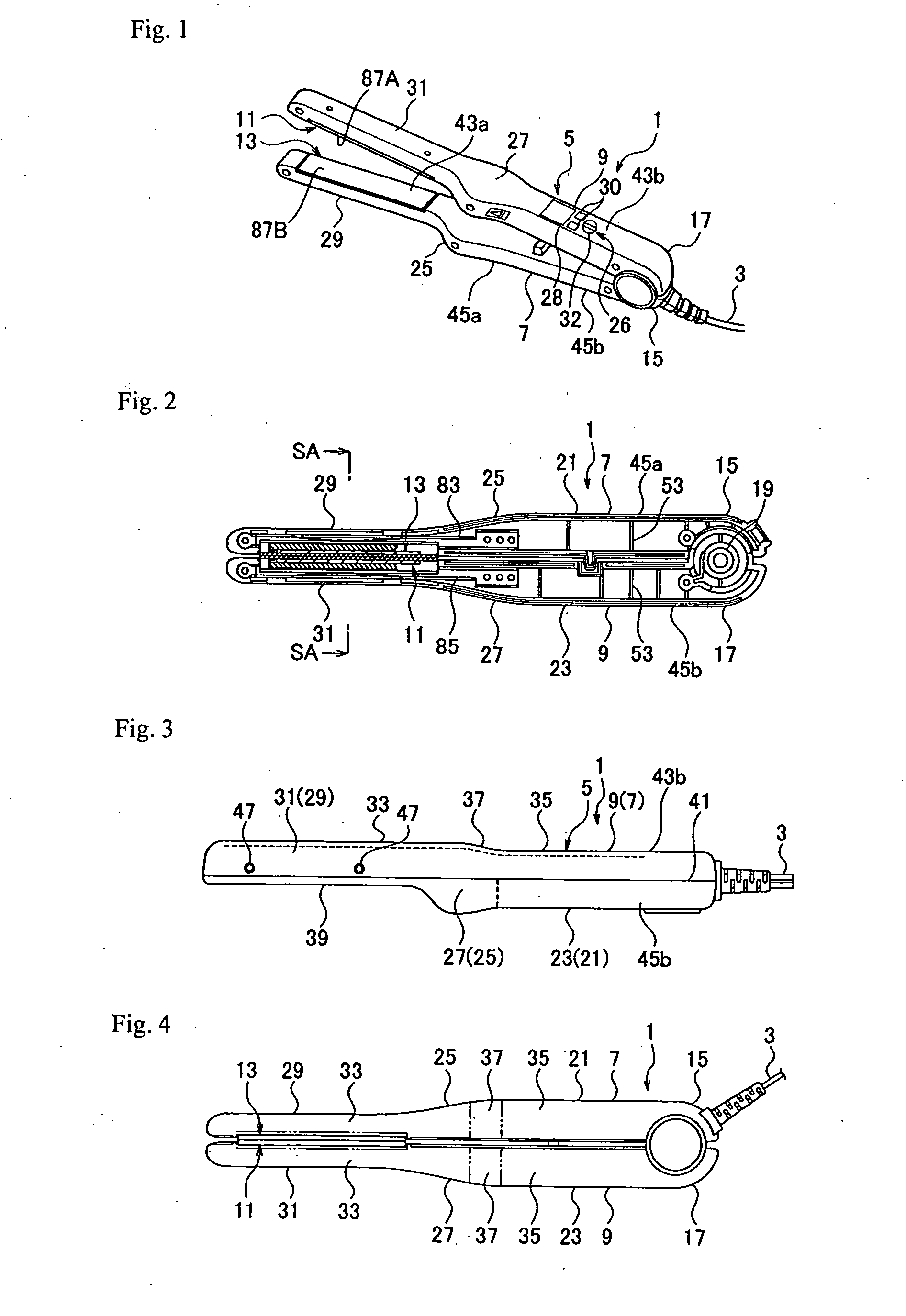

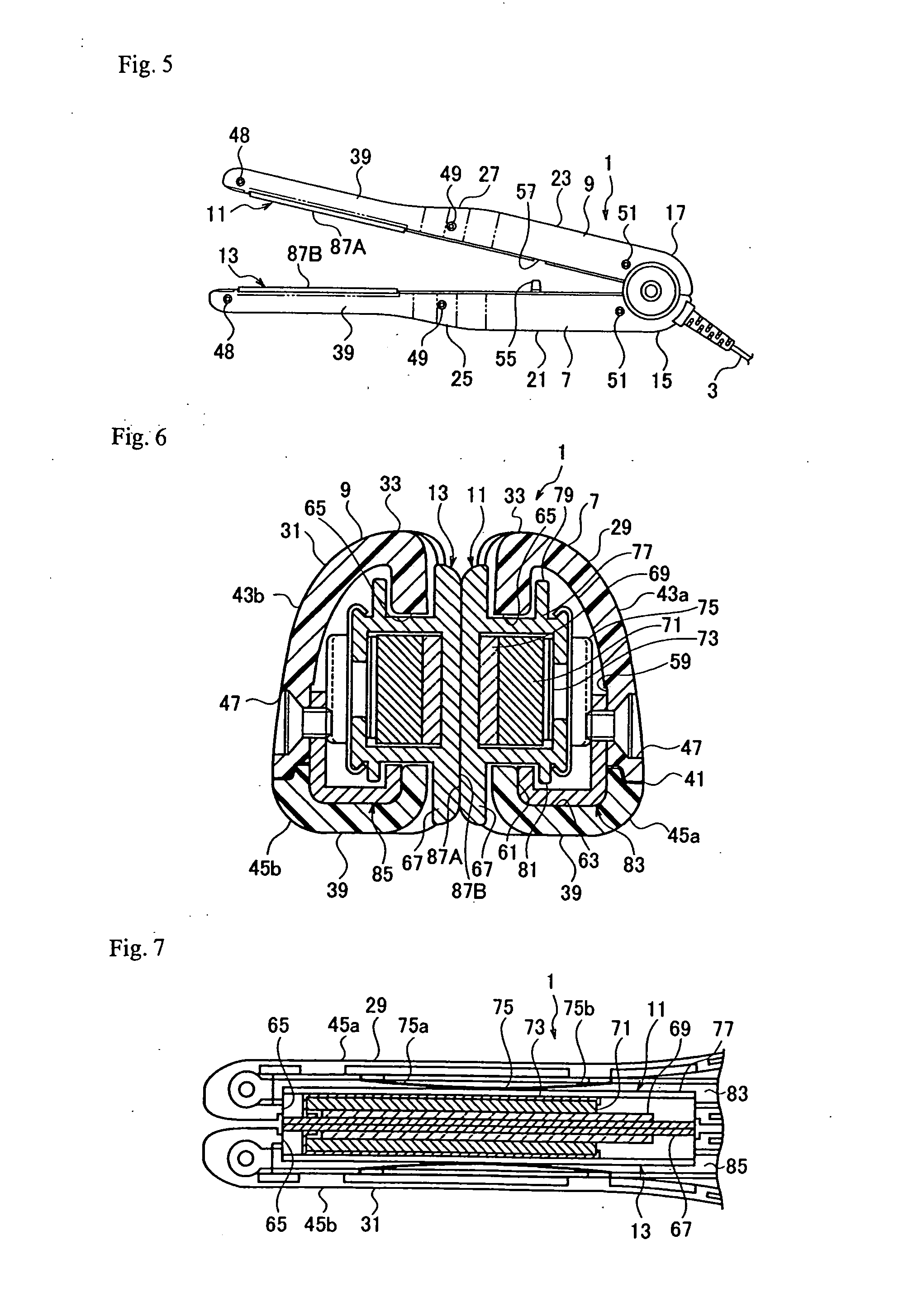

[0027]FIGS. 1 to 5 show a hair iron according to an embodiment of the present invention, in which FIG. 1 is a general perspective view partly omitted, FIG. 2 a plan view partly broken with divisional parts removed, FIG. 3 a side view, FIG. 4 a plan view, and FIG. 5 a bottom view with clamp arms opened.

[0028]As shown in FIGS. 1 to 5, the hair iron 1 has an iron body 5 to which a power source cord 3 is connected. The power source cord 3 is provided with a power source plug and the like.

[0029]The iron body 5 has a pair of clamp arms 7 and 9 and a pair of correctors 11 and 13. The clamp arms 7 and 9 are made of resin such as C-polyester-based...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com