Versatile leg for a roof rack

a technology of roof racks and legs, applied in the field of vertical legs, can solve the problems of high stock levels of retailers, increased production costs, and drawbacks of manufacturers, and achieve the effect of reducing their stock levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

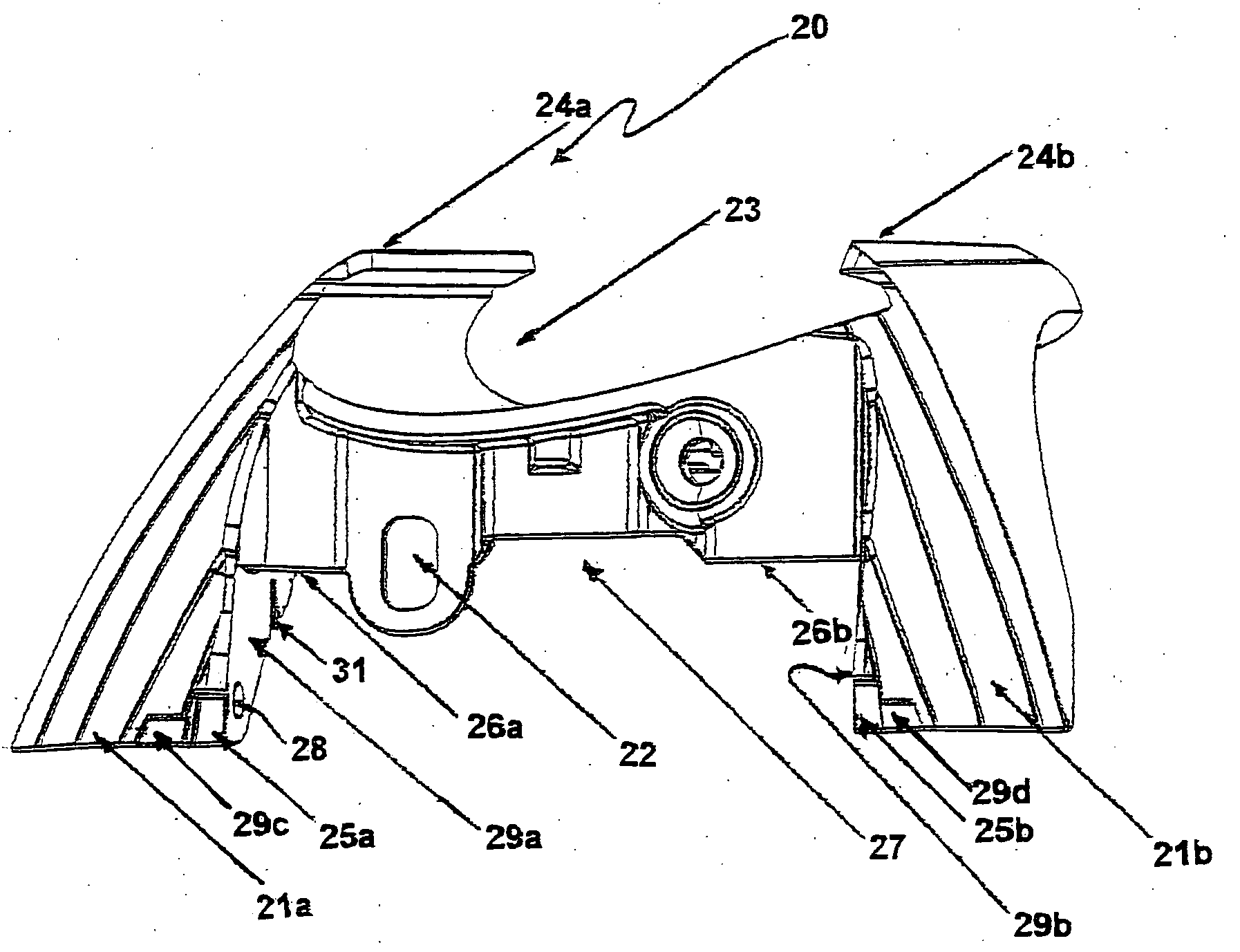

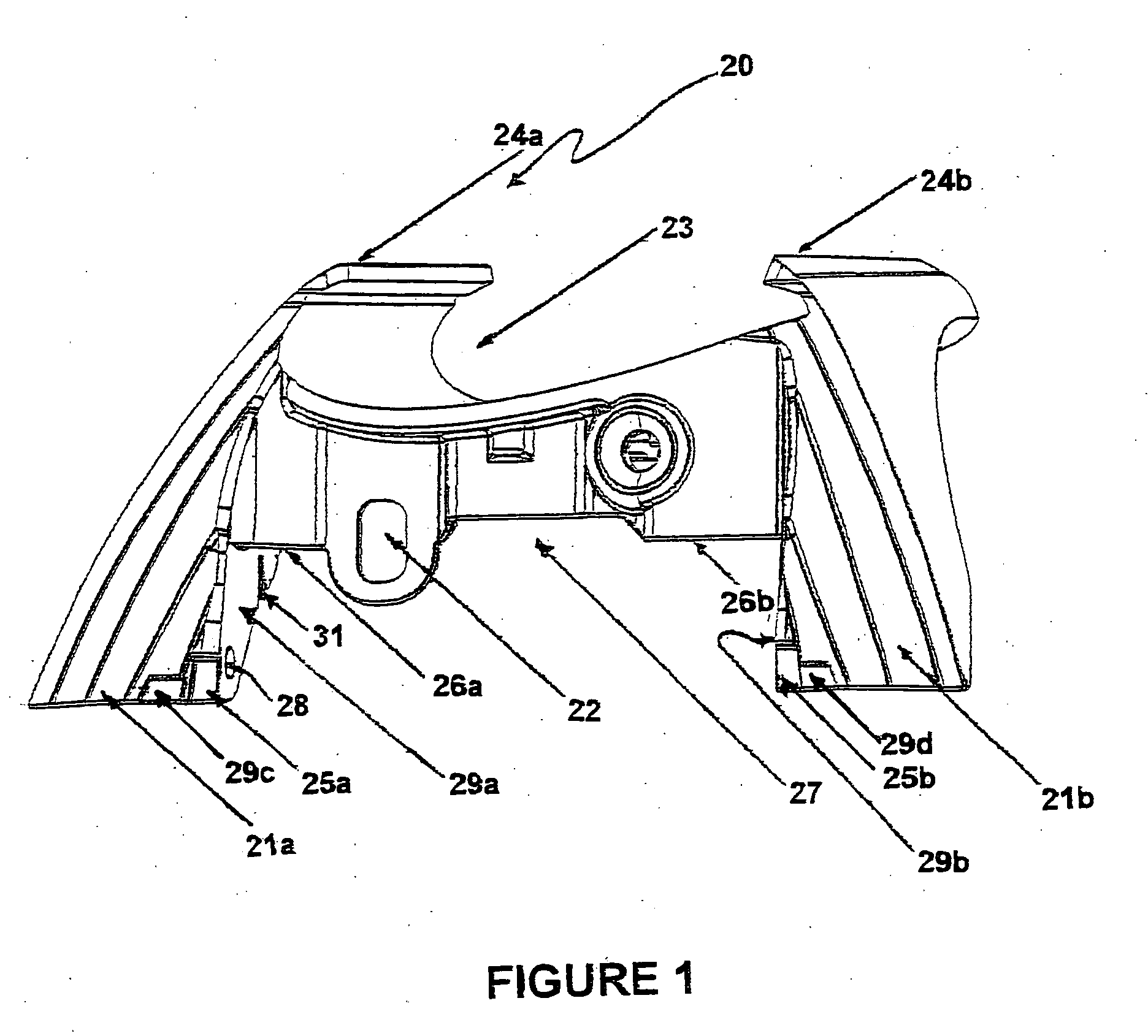

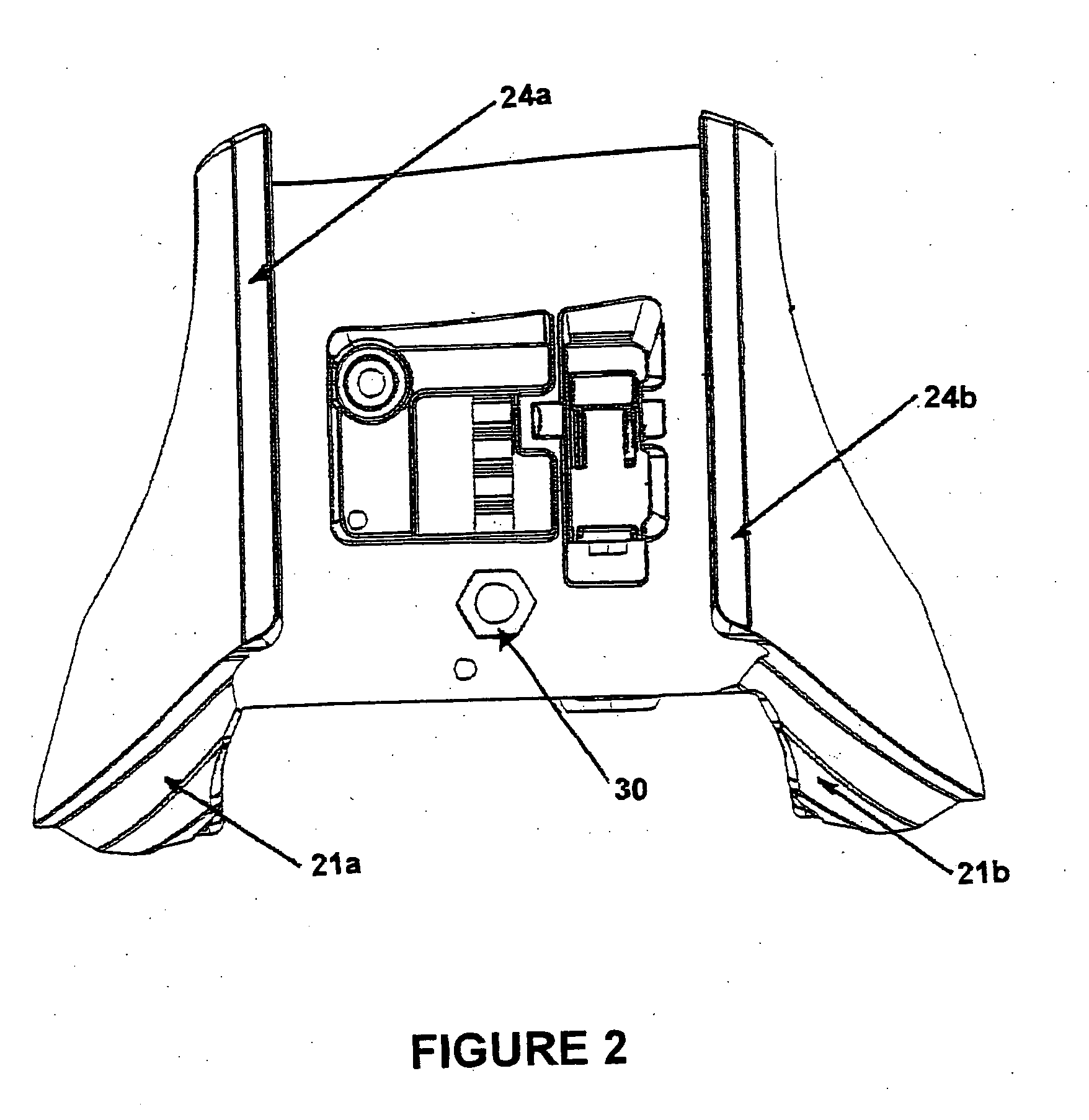

[0071]According to one embodiment of the invention, there is provided a leg 20 for a roof rack. The roof rack typically comprises a pair of legs at each end of a crossbar, the legs being used to support the crossbar and to directly or indirectly attach the roof rack to a vehicle. To attach the roof rack to a vehicle, the leg is adapted for coupling to a plurality of different mounting systems. Thus, separate mounting means may be used to attach the leg to the vehicle. Because the same leg can be used with a plurality of different mounts, a manufacturer and retailer can provide a lesser number of different components in a roof rack kit than in conventional roof rack kits. A standard kit comprising a crossbar and a pair of legs can be provided and separate kits for each mounting system can also be provided. Therefore, a consumer can purchase a standard kit together with whichever mounting system is required for the vehicle to which the roof rack will be attached.

[0072]FIG. 1 is a pers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com