Moldable arch support for footwear

a technology of arch support and footwear, which is applied in the field of inserts for footwear, can solve the problems of foot muscle, foot muscles, bones, ligaments, etc., and achieve the effect of reducing the risk of injury, and improving the stability of the foo

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029]The following description of the preferred embodiment(s) is merely exemplary in nature and is in no way intended to limit the invention, or uses.

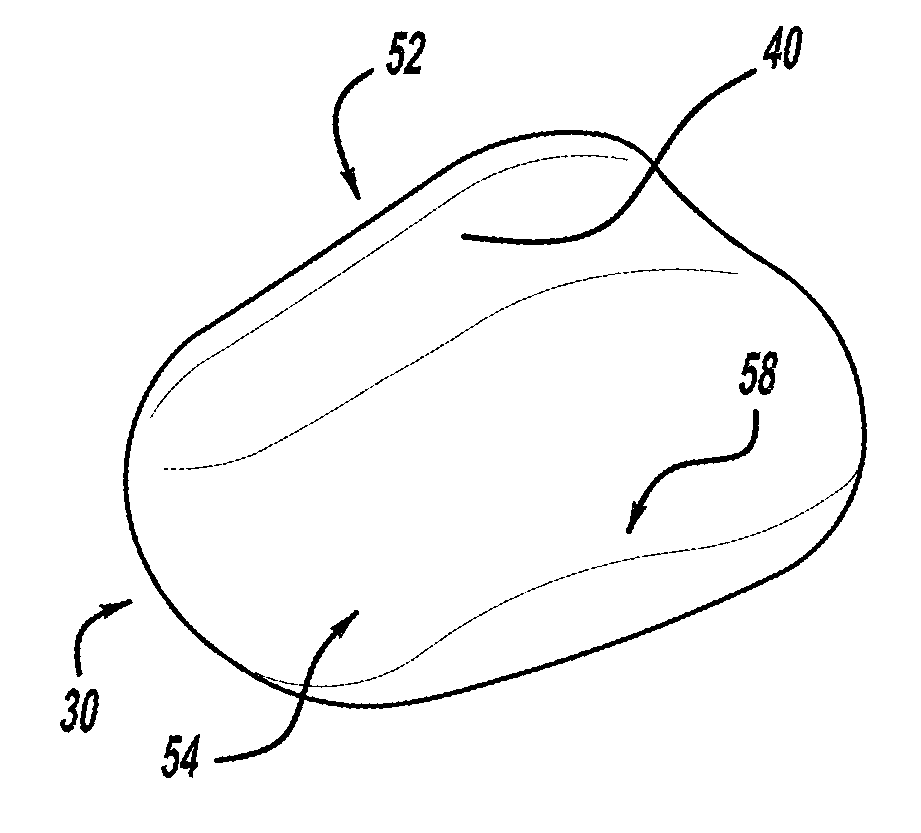

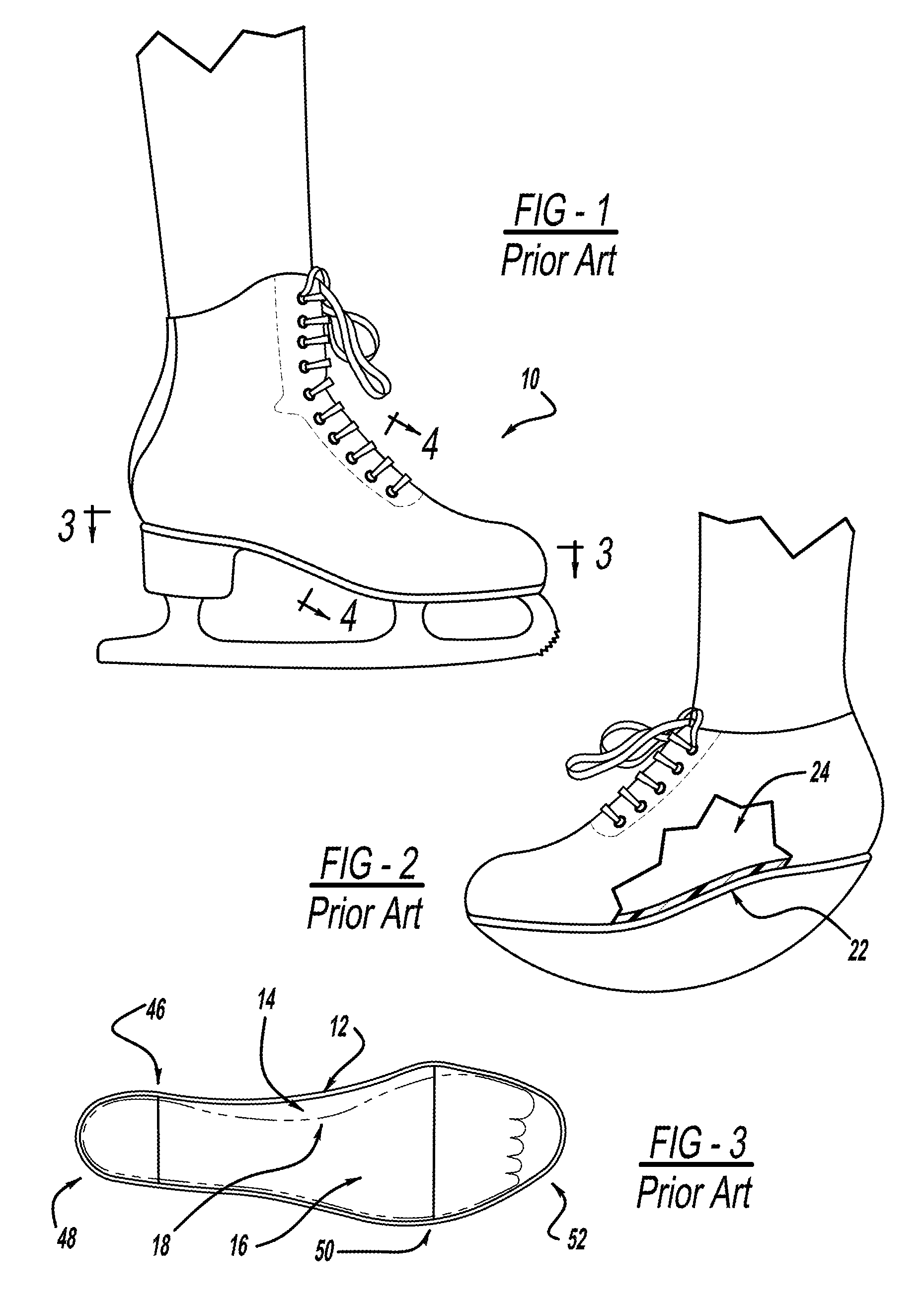

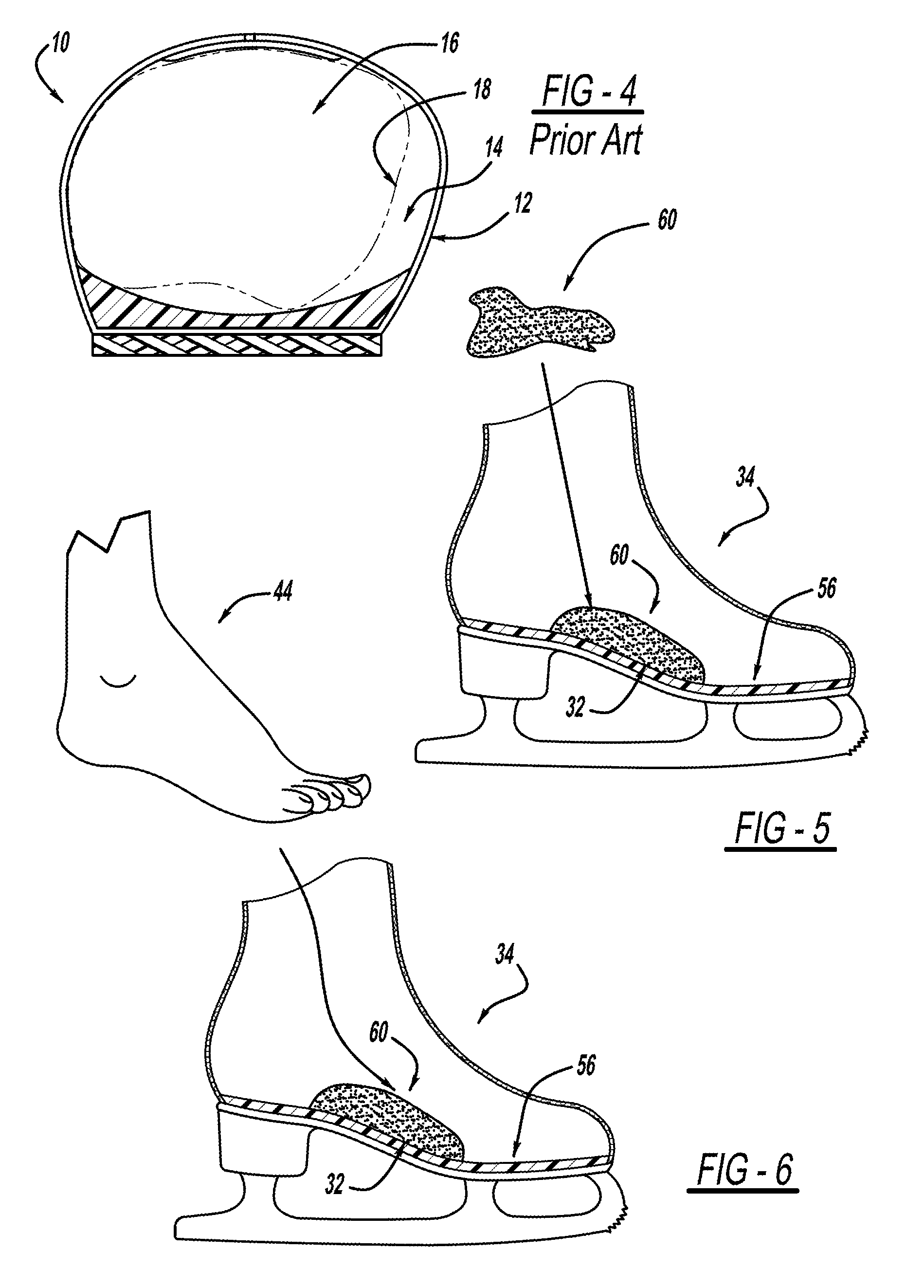

[0030]Referring to FIGS. 5-10, a new and improved molded insert 30 is provided for an arch cavity 32 of a piece of footwear, e.g., a boot 34, such as, but not limited to ice skating boots, or an arch cavity 36 of a shoe 37, such as, but not limited to exercise, therapeutic, or physiological footwear. By “arch cavity,” as that phrase is used herein, it is meant any cavity, space, volume and / or the like adjacent to and / or proximate to the arch of the foot when it is placed in a piece of footwear.

[0031]The molded insert 30 can be formed of any moldable material that is substantially firm, yet comfortable, when cured or dried. The moldable material can be used to fill in, at least substantially, the volume of the arch cavity 32, 36 to form a substantially firm, yet comfortable, surface 40 for supporting the arch 42 of the wearer's foot 44...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com