Driving device for taking away filling material from a surface

a technology of filling material and driving device, which is applied in the direction of cleaning filter means, suction cleaners, constructions, etc., can solve the problems of reducing the performance of filter elements continuously, loosing their function, and high cost of filter elements or new filter elements exchange, etc., and achieves low service times and large availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

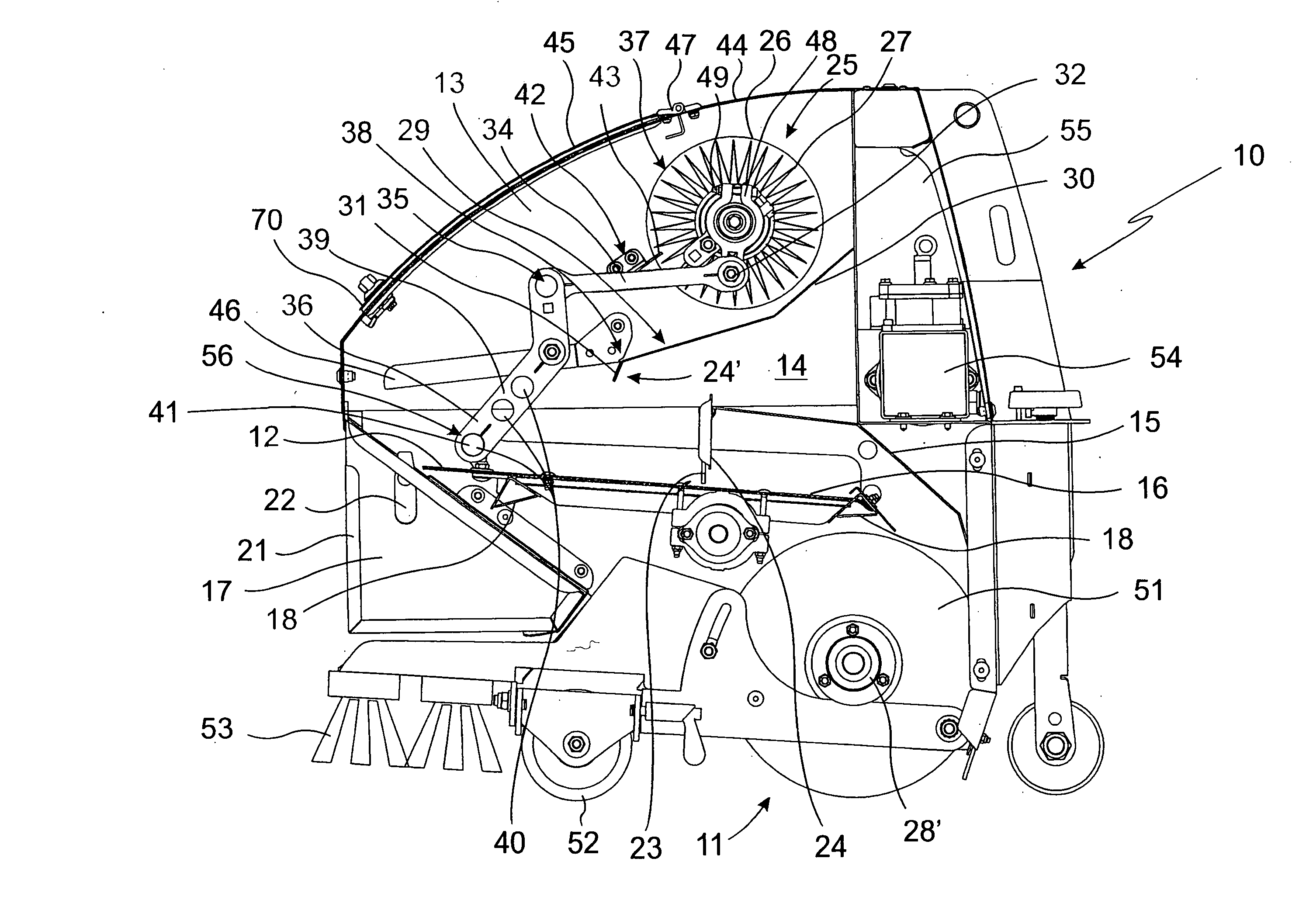

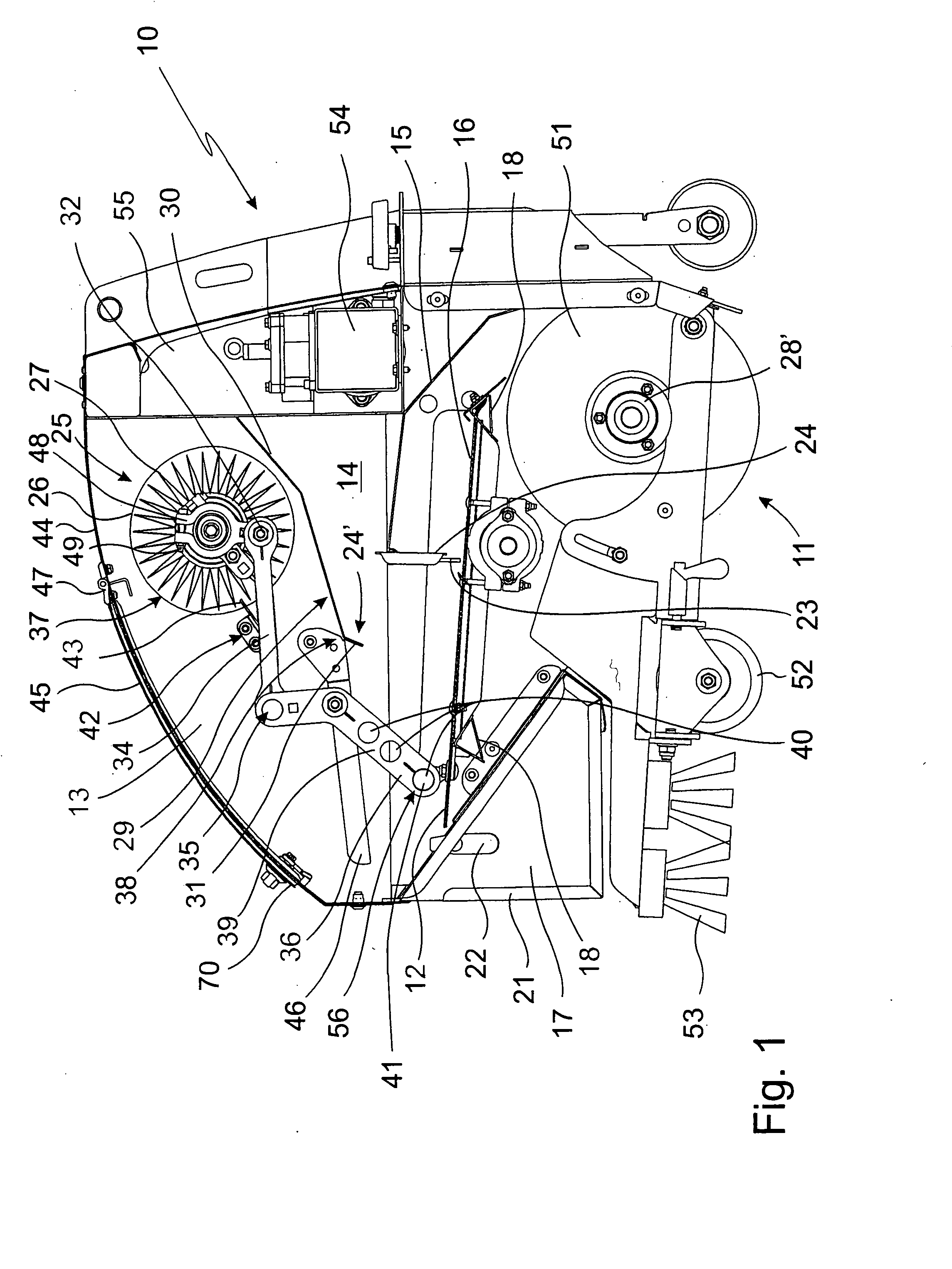

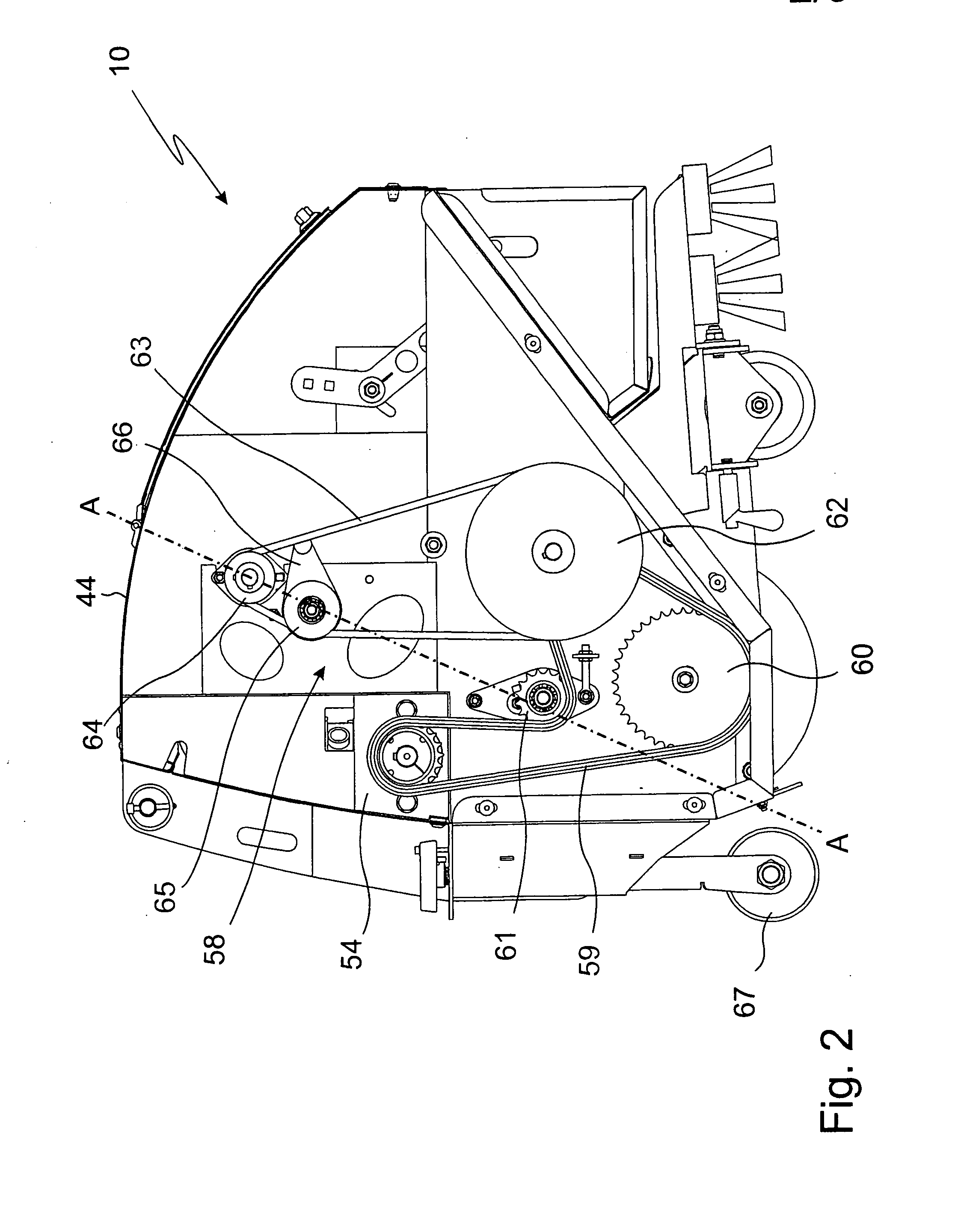

[0038]FIG. 1 shows a preferred embodiment of a driving device 10 comprising a taking-away device 11. Filling material, dirt and other particles can be taken away from a surface by the driving device 10. Generally, the driving device 10 is suited for cleaning surfaces of all kind, also with solid soil. However, it is in particular convenient when the driving device 10 is used on a sports field, and her preferably on an artificial lawn field. Besides the picking up of the filling material of the artificial lawn field and putting it on the field again, a cleaning of the filling layer characterizing the qualities of the artificial lawn is carried out. The driving device 10 has in its interior 14 a guiding plate 15. This guiding plate 15 serves for guiding filling material fed in the driving device 10 by the taking-away device 11, mixed with dirt and particles, to a sieve 16 arranged centrally in the driving device 10. The sieve 16 extends over the entire width of the driving device 10 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com