Shoelace replacement system and method

a shoelace and replacement system technology, applied in the direction of shoelace fastenings, fastenings, footwear, etc., can solve the problems of easy soiled eyelets, easy smudging, and easy insertion of shoelaces into shoes, so as to facilitate or casually remove eyelets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

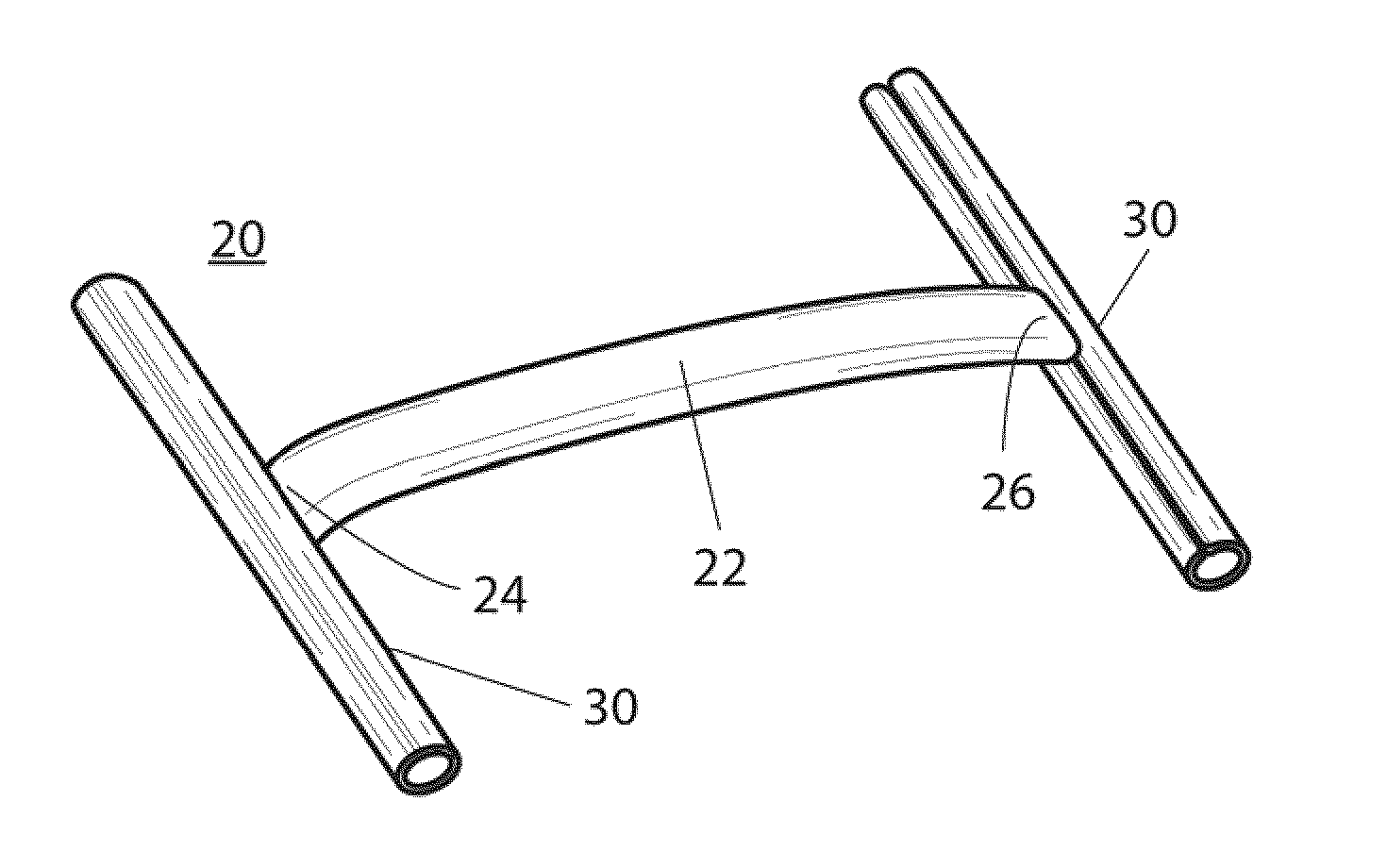

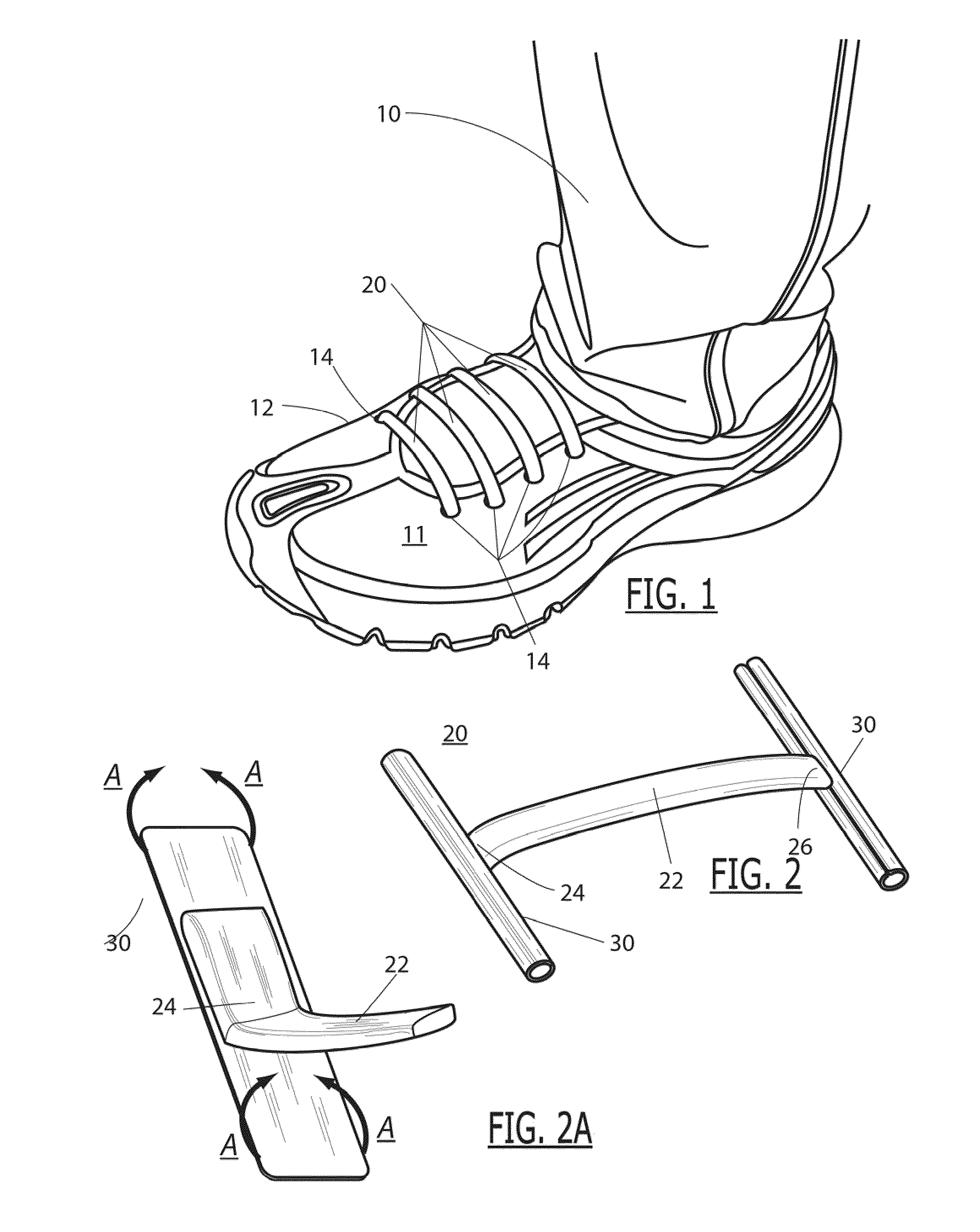

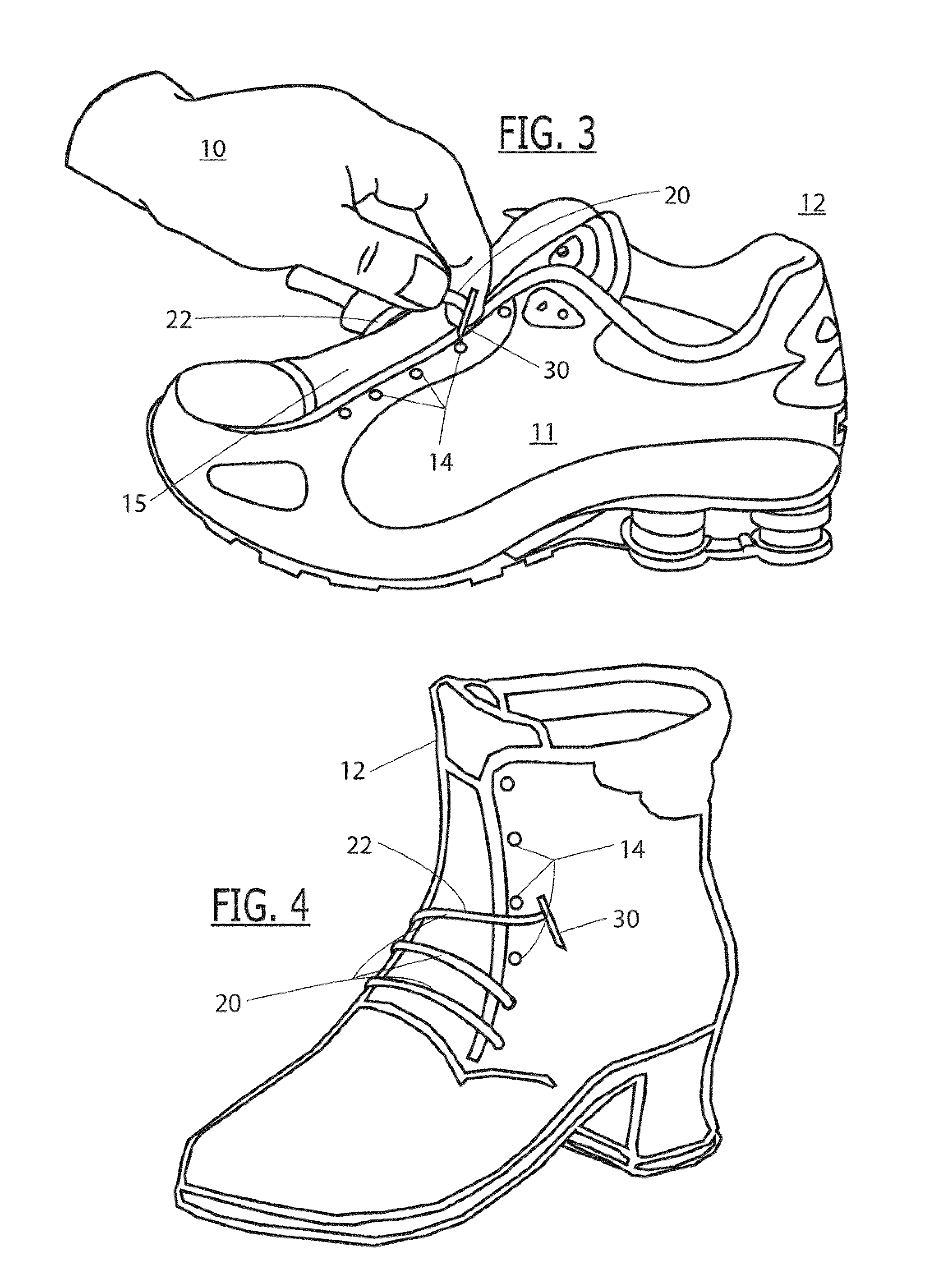

[0022]Referring now to the drawings, the present invention is illustrated in an environmental view in FIG. 1. A user or wearer 10 is wearing an athletic shoe 12 on his or her foot. A conventional shoelace, as used (not depicted), a single length of lace material would be threaded in a criss-cross pattern through an alternating sequence of eyelets 14. Because a conventional shoelace is a single length of material, each segment of the shoelace (the term “segment” being defined as the portion of the shoelace between any two eyelets) operates dependently with the other segments.

[0023]For example, when conventional laces are used, the shoe cannot be truly loosened except by increasing the amount of lace material between each pair of eyelets, an operation that requires the entire lace to be shifted through successive eyelets. Additionally, when a conventional lace is used to lace up the shoe, great care must be taken to keep the lace ends even as the shoe is laced, lest the wearer be left...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com