Rotary compressor and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

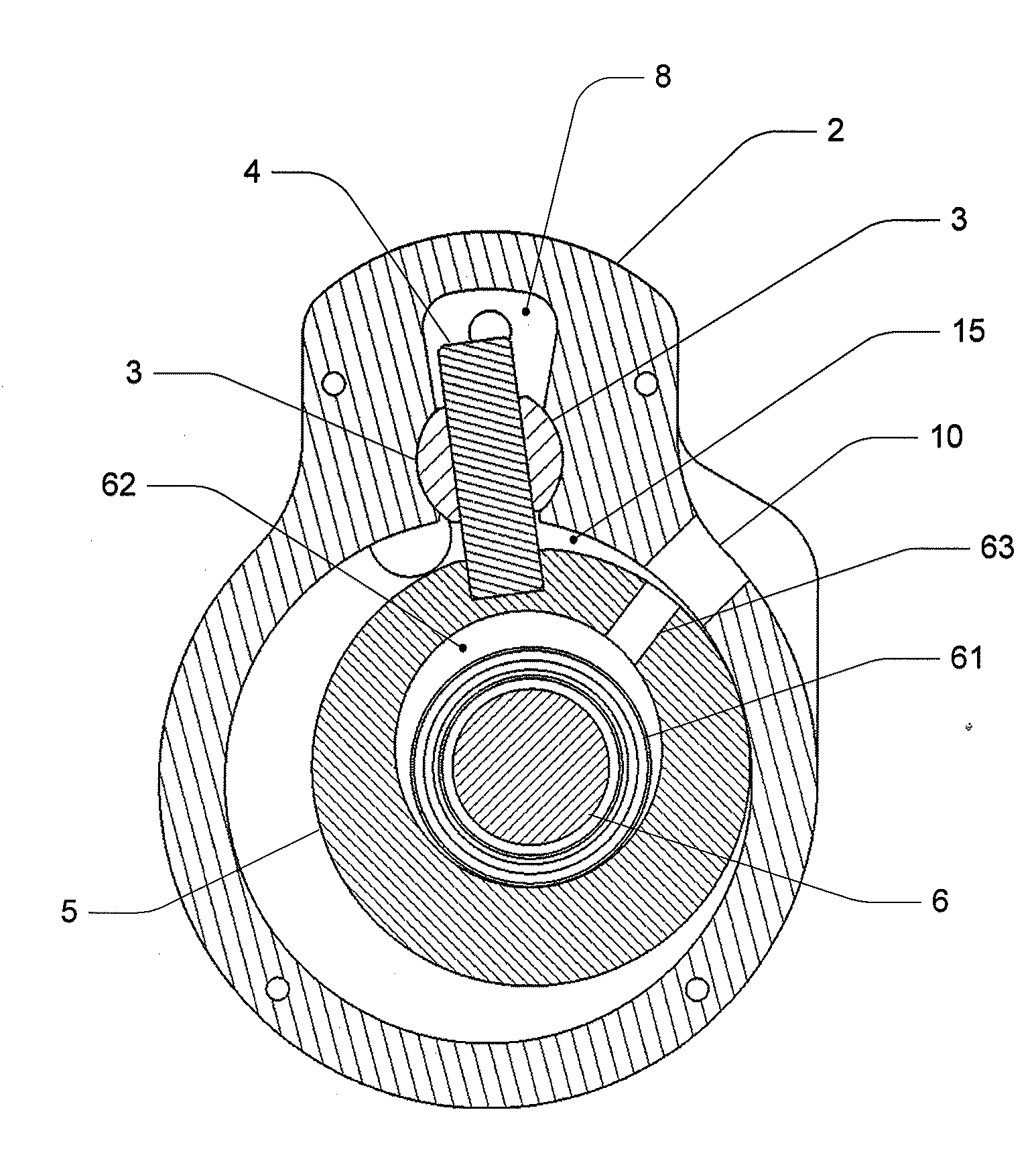

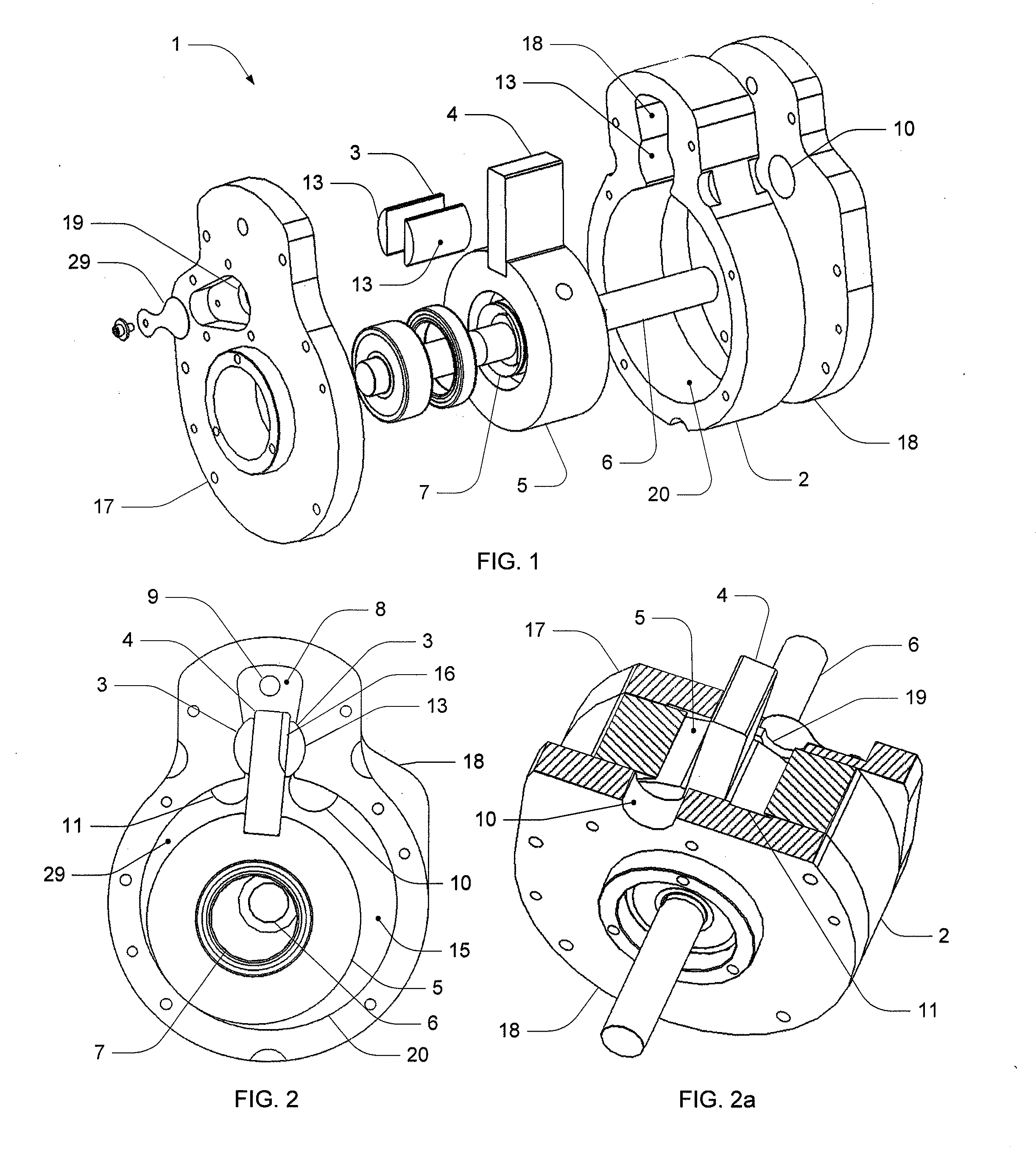

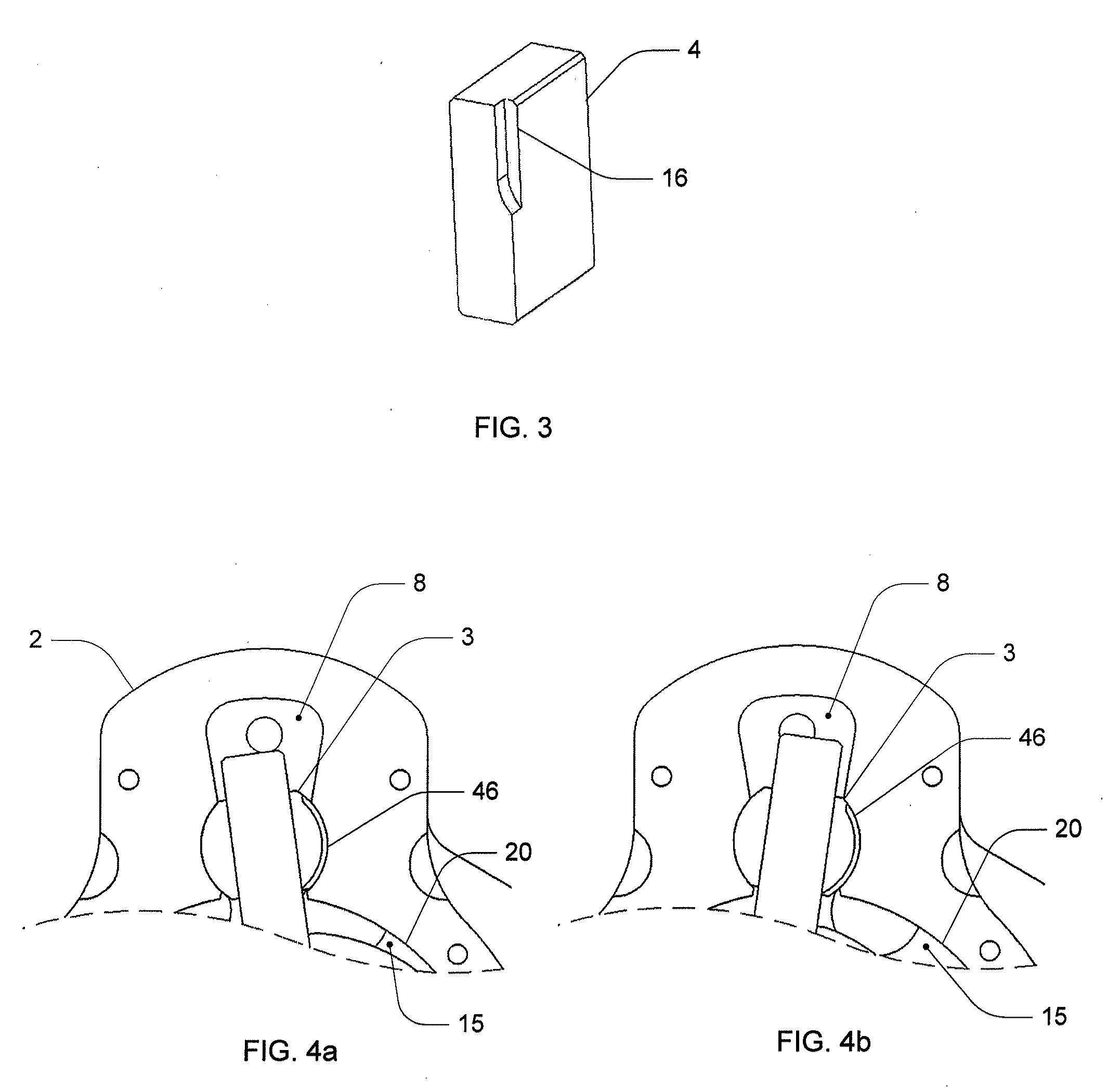

[0056]With reference to FIGS. 1-25b, multiple embodiments of a rotary compressor and method will be shown and described.

[0057]FIG. 1 shows an exploded view of a rotary compressor 1. An exemplary rotary compressor 1 of the disclosure includes several inter-related parts.

[0058]For instance, the compressor includes a housing. The housing may be formed as a stator 2 and may include two endplates, for instance, a discharge end plate 17 and a suction end plate 18. As depicted, the discharge end plate 17 includes a discharge port 19, and the suction endplate 18 includes a suction port 10. It is to be noted that although the discharge and suction ports are depicted herein as being associated with respective endplates, in other embodiments, one or both ports may be associated with a single endplate or other parts of the compressor housing. Also, it is to be noted that although the endplates are depicted as separate components from the housing, an endplate can be an integral part of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com