Unlimited Downhole Fracture Zone System

a fracture zone and unlimited technology, applied in the direction of fluid removal, borehole/well accessories, construction, etc., can solve the problems of limited number of unique seats, reduced production from the lower zone, and open up the possibility of mis-ordering the balls, so as to increase production and accidental isolation of the fracture zone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

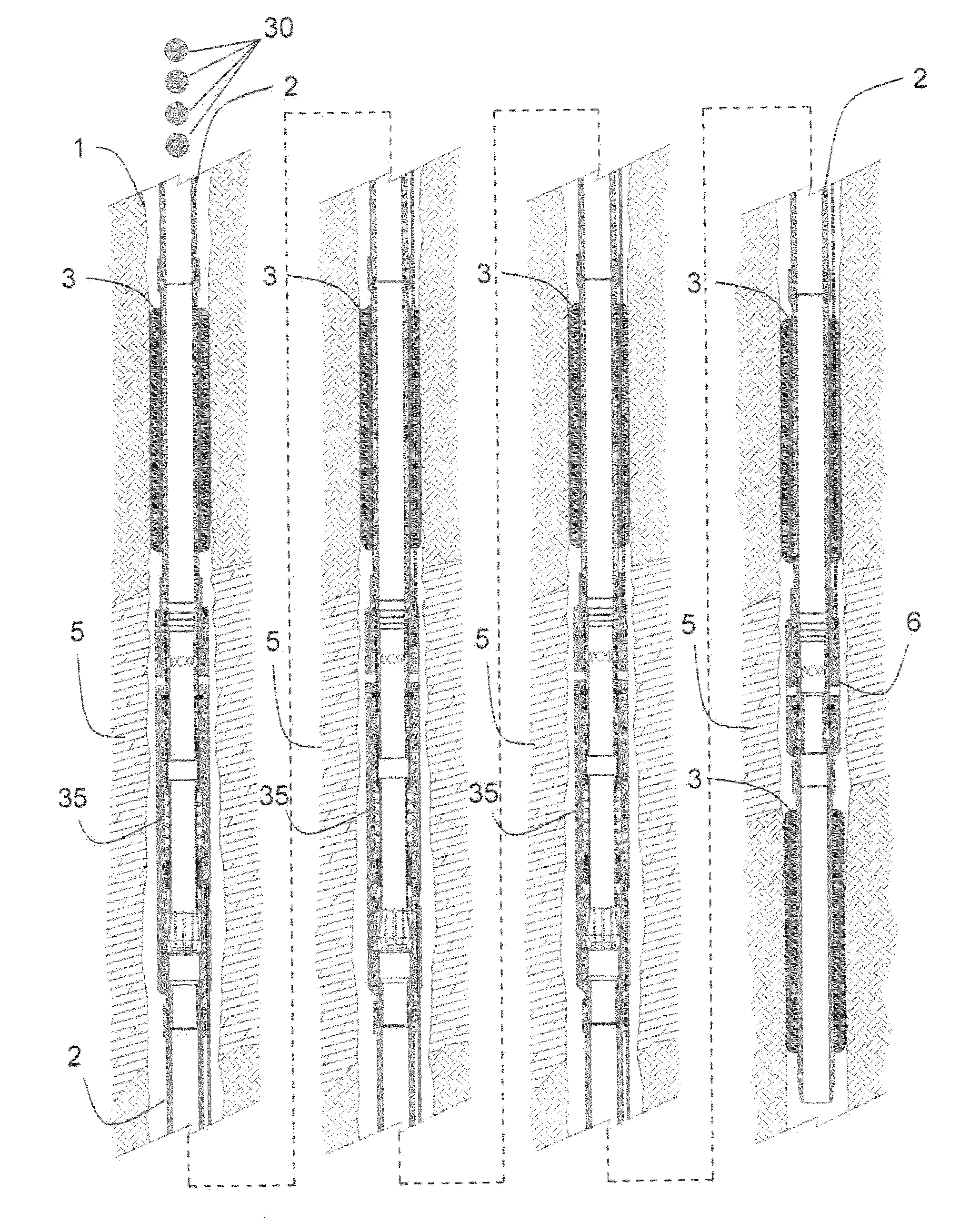

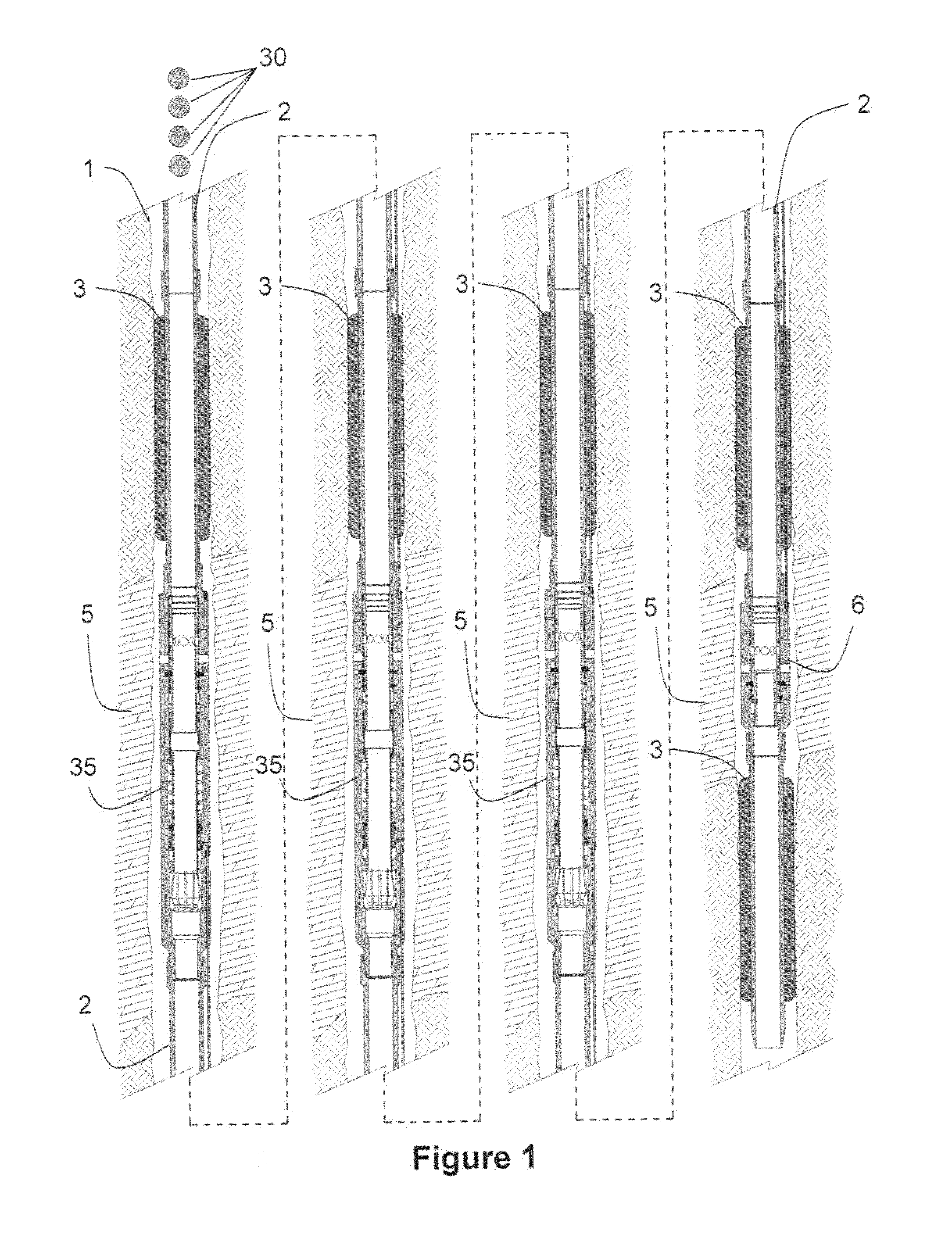

[0022]FIG. 1 illustrates an embodiment of the system deployed within a well bore 1. The system includes tubing 2, packers 3, a plurality of diverter valves 35, and lower initiation tool 6. Lower initiation tool 6 and diverter valves 35 are positioned within zones 5 using suitable tubing 2. Zones to be treated (called “fracturing zones” herein) 5 are isolated by positioning known packers 3 above and below the diverter valves and the lower initiation tool. Fracturing zones 5 are illustrated as separated by non-productive segments in the figure, which would apply in a vertical well or wellbore at an angle that penetrates both productive and non-productive zones. In a horizontal portion of a well, the non-productive zones may not be present.

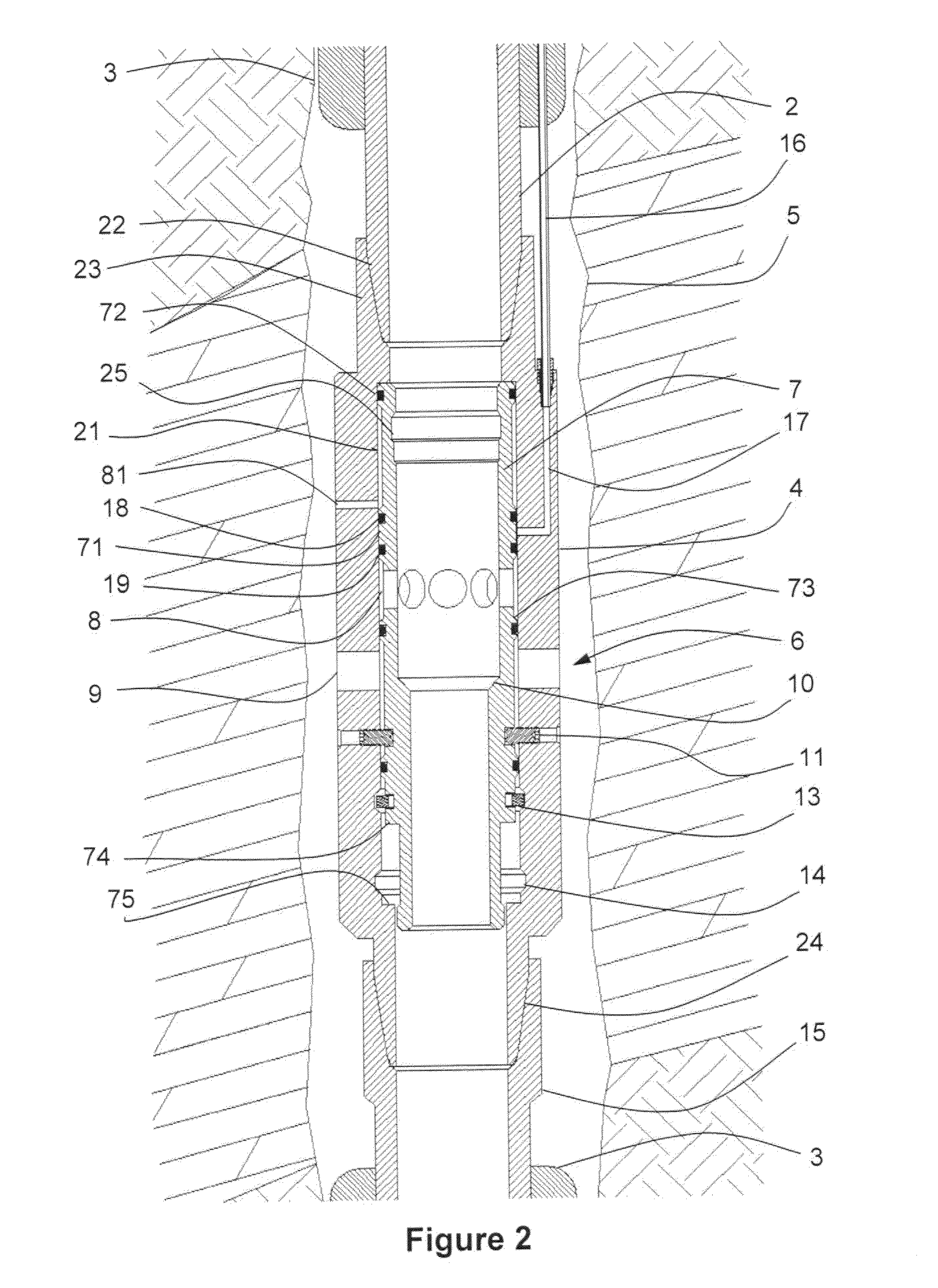

[0023]Referring to FIG. 2, the lower initiation tool 6 includes a housing 4, which at its lower end 24 is adapted for connection to tubing 15 by any suitable means such as screw threads. The upper portion of the housing 23 is similarly adapted for at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com