Shelf to twin-post support assembling structure for sectional rack

a technology of assembling structure and support, which is applied in the direction of dismountable cabinets, sectional furniture, furniture parts, etc., can solve the problems of poor structural strength of the above-structured sectional rack and the tendency to wobble sidewards, and achieve the effect of increasing the overall structural strength of the fully assembled sectional rack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020]The present invention will now be described with some preferred embodiments thereof. For the purpose of easy to understand, elements that are the same in the preferred embodiments are denoted by the same reference numerals.

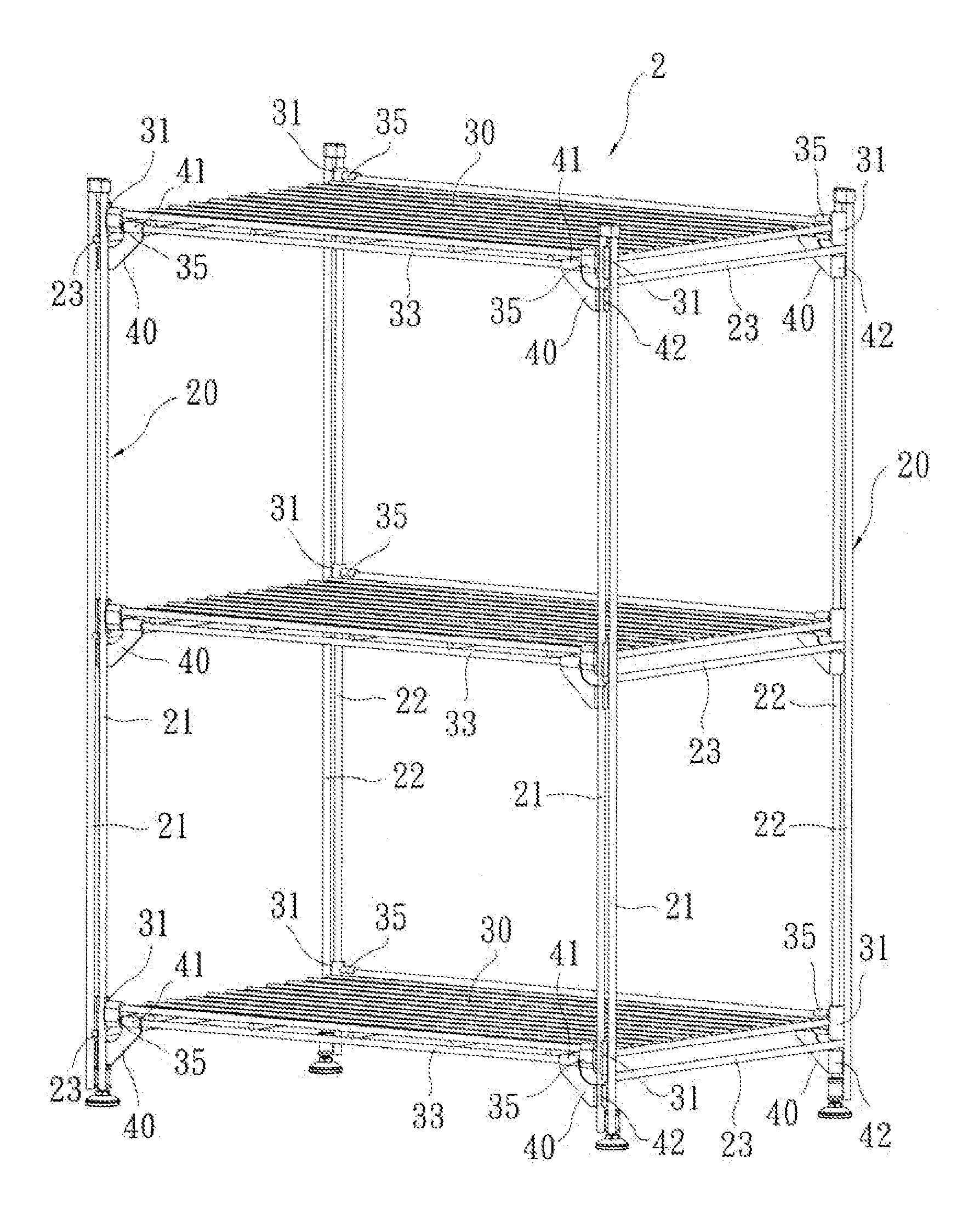

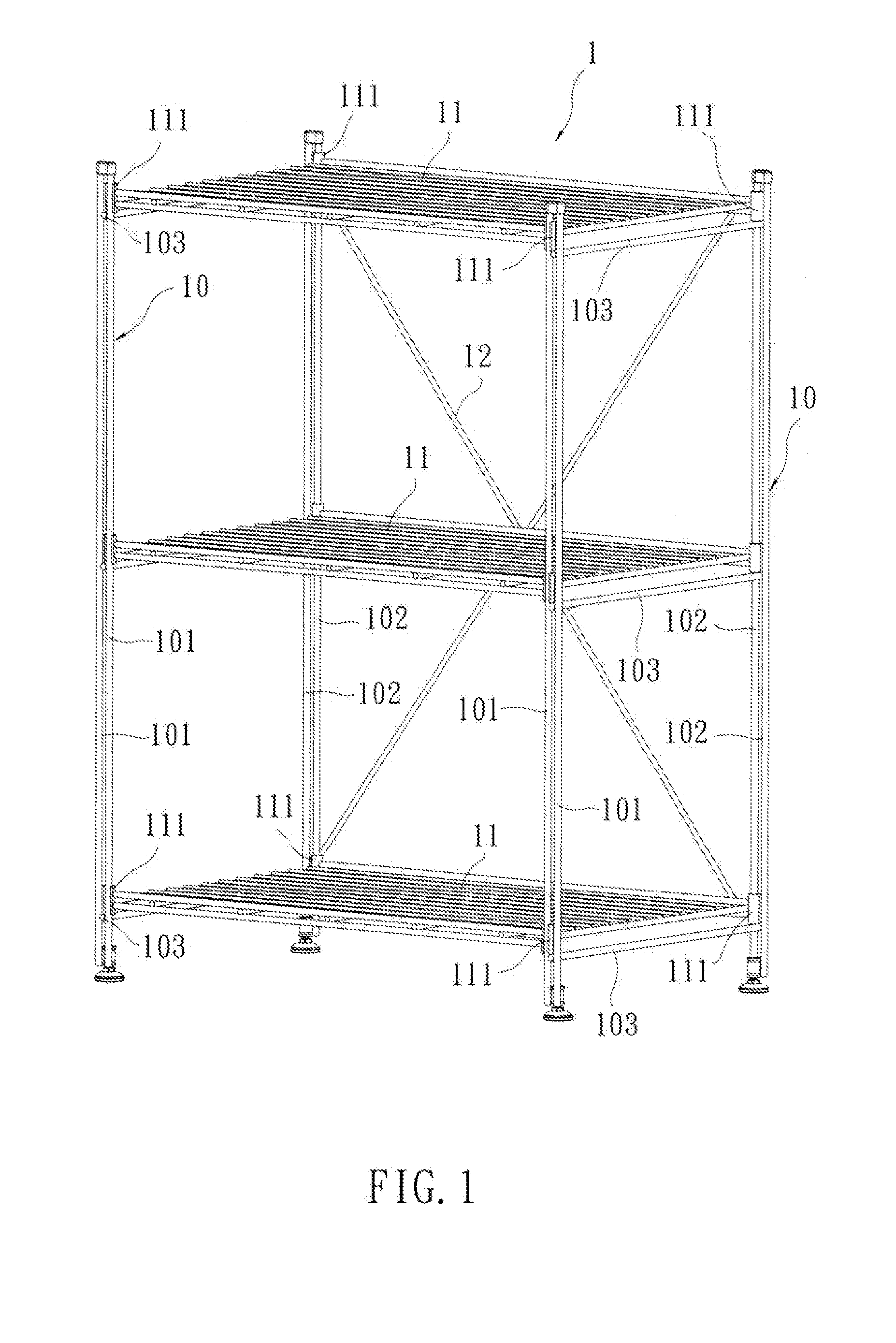

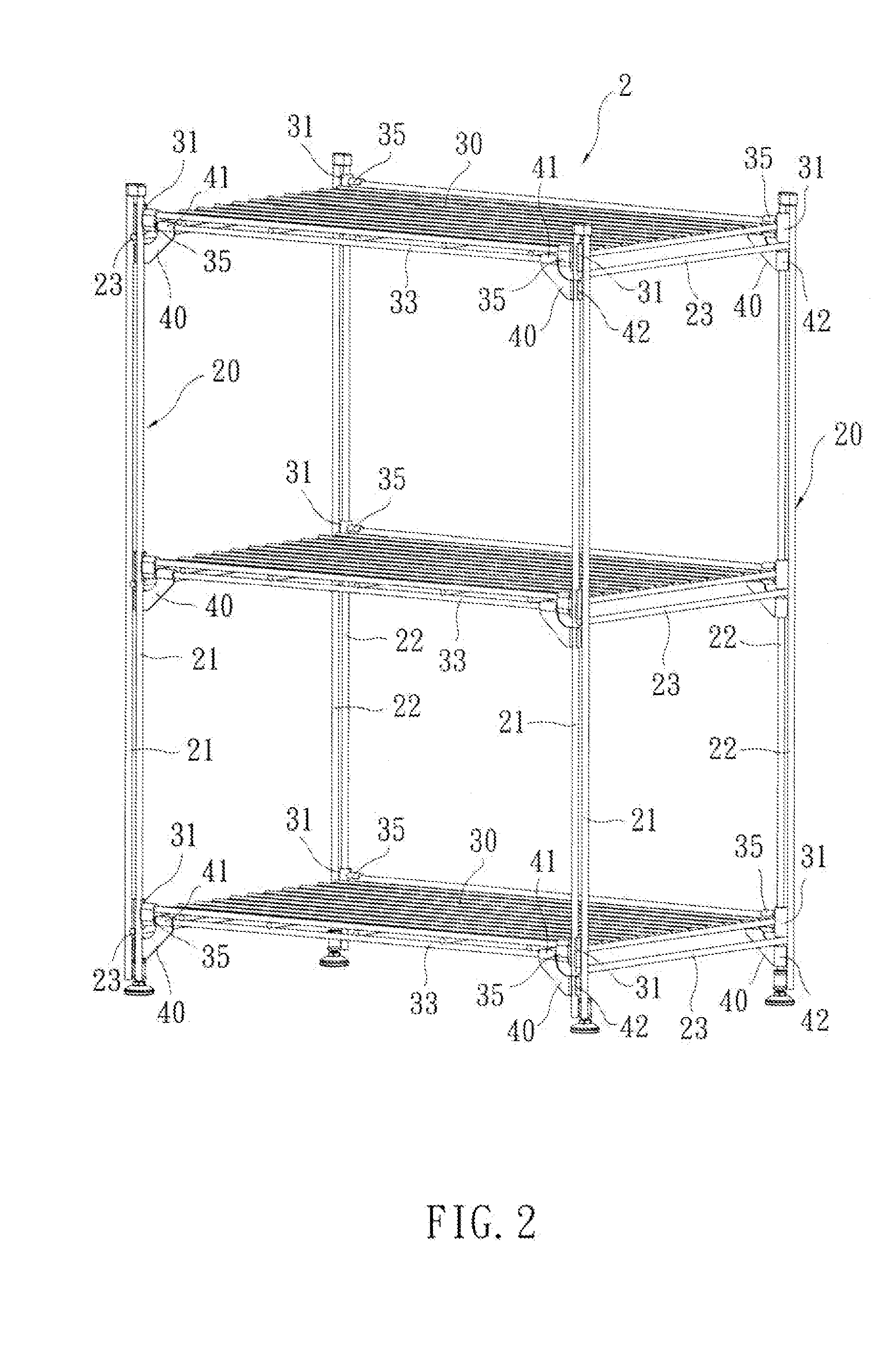

[0021]Please refer to FIGS. 2, 3 and 4. A shelf to twin-post support assembling structure for sectional rack according to the present invention enables the assembling of a shelf 30 at four corners to two side support frames 20 to thereby form a sectional rack 2 for use. A fully assembled sectional rack 2 includes at least two side support frames 20, and at least two shelves 30. A first embodiment of the sectional rack 2 illustrated in FIG. 2 is assembled from two side support frames 20 and three shelves 30.

[0022]Each of the side support frames 20 includes a front twin-post support having two juxtaposed front posts 21, a rear twin-post support having two juxtaposed rear posts 22, and at least two (three are shown in the drawings) vertically spaced horizontal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com