Ballast removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

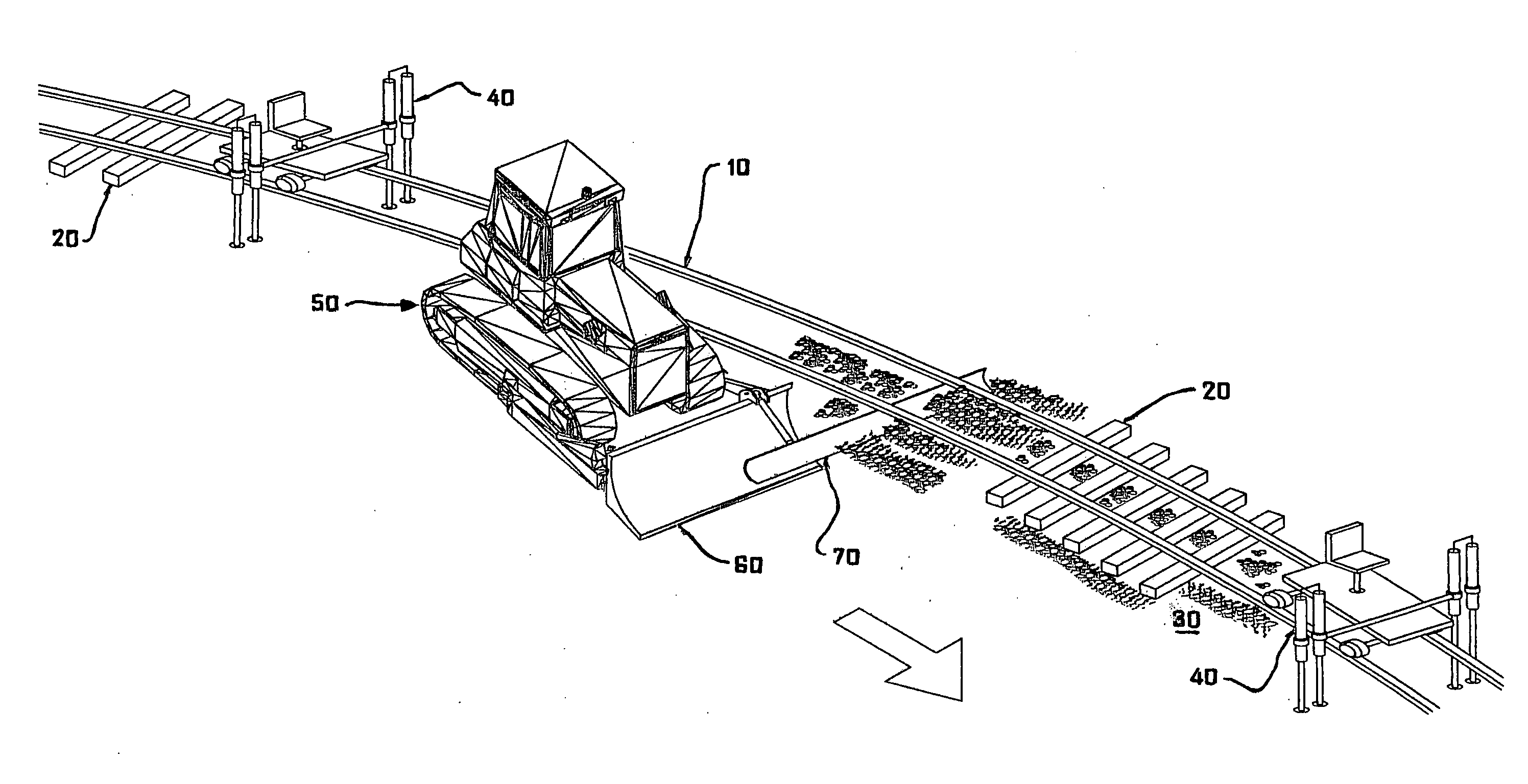

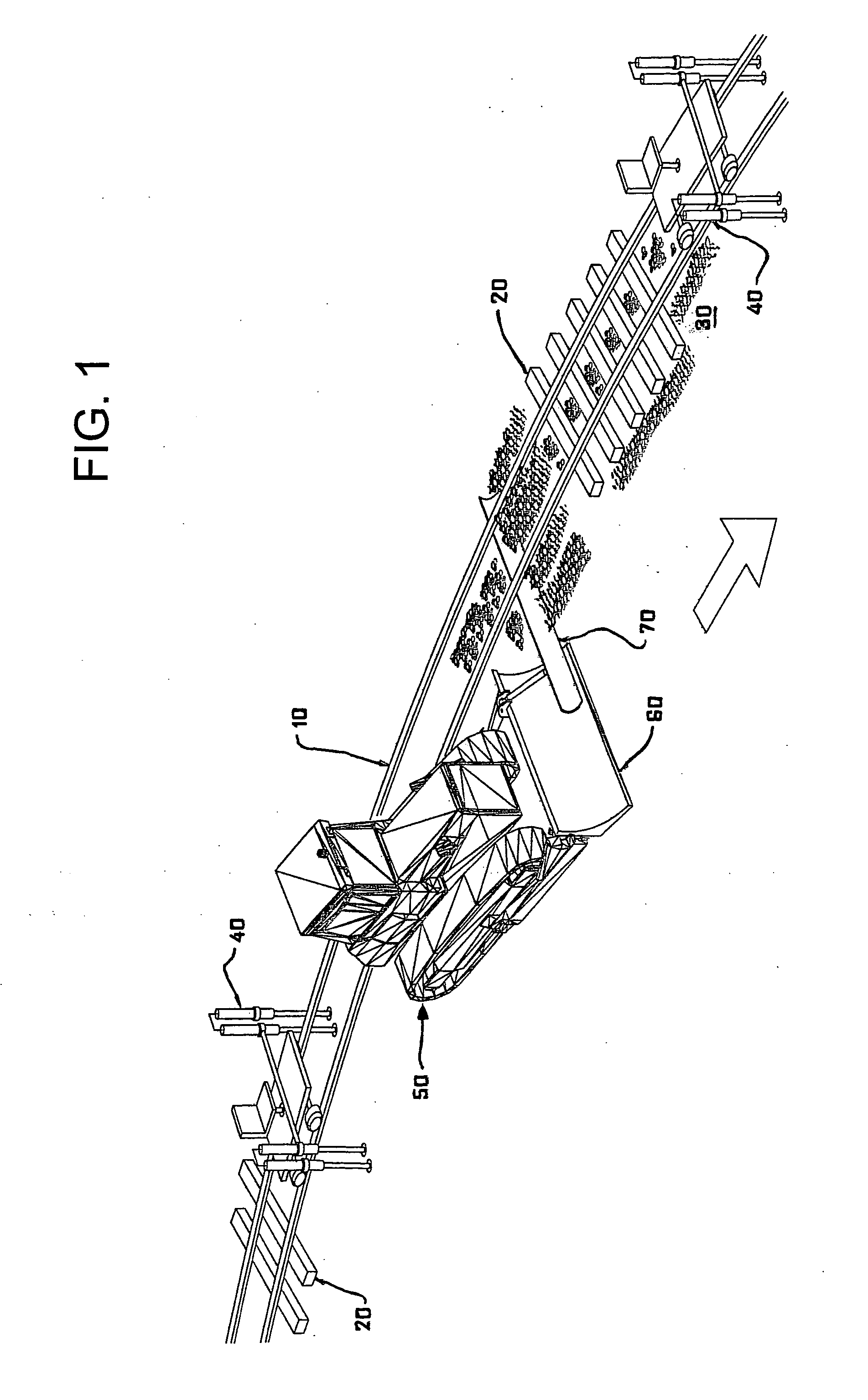

[0013]This invention is best understood by reference to the drawings. Referring to FIG. 1, a section of railway track consisting of rails 10 and ties 20 (only portions of which are shown for clarity) is elevated above a bed of ballast 30 by two railway jacks 40 that are spaced about 50 to 200 feet apart. Suitable railway jacks are well known in the industry and are available from many different manufacturers.

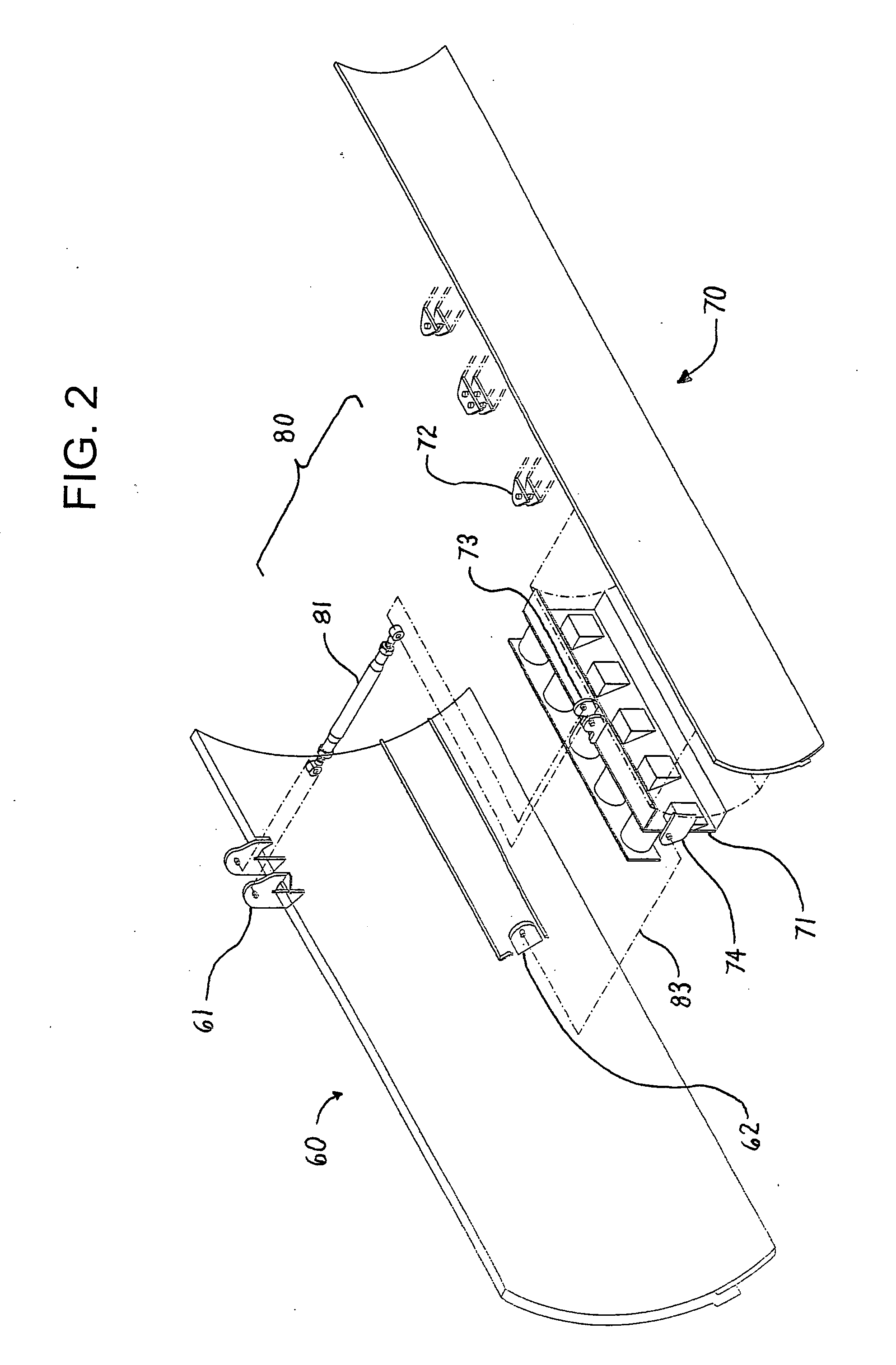

[0014]A bulldozer 50 having a front blade 60 is positioned alongside the section of elevated railway track. The position of the blade is controllable by the operator from inside the cab. The bulldozer is conventional except for an elongated rake 70 attached to the front blade. The means for attachment 80 is a matter of choice and can be permanent (e.g., the rake can be welded to the blade) or temporary (i.e., the rake is able to be attached to and removed from the blade in a relatively short time). The means for attachment is preferably temporary so the bulldozer can be used in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com