Releasable tie

a tie and releasable technology, applied in the field of cable ties, can solve the problems of inconvenient use of conventional ties, waste of resources, and inconvenient use of ties, and achieve the effect of maximizing the friction between the arm and the finger of the user

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

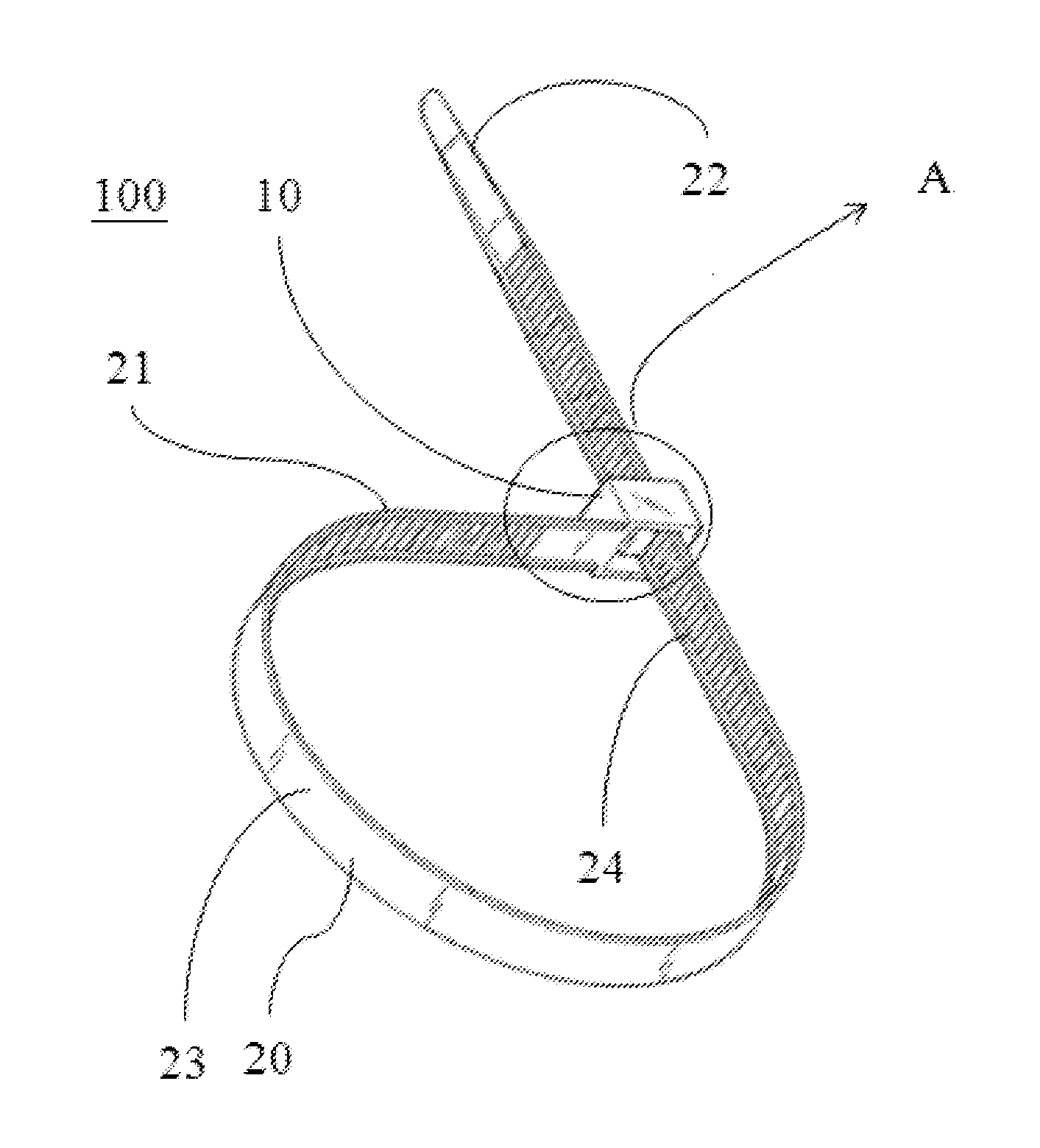

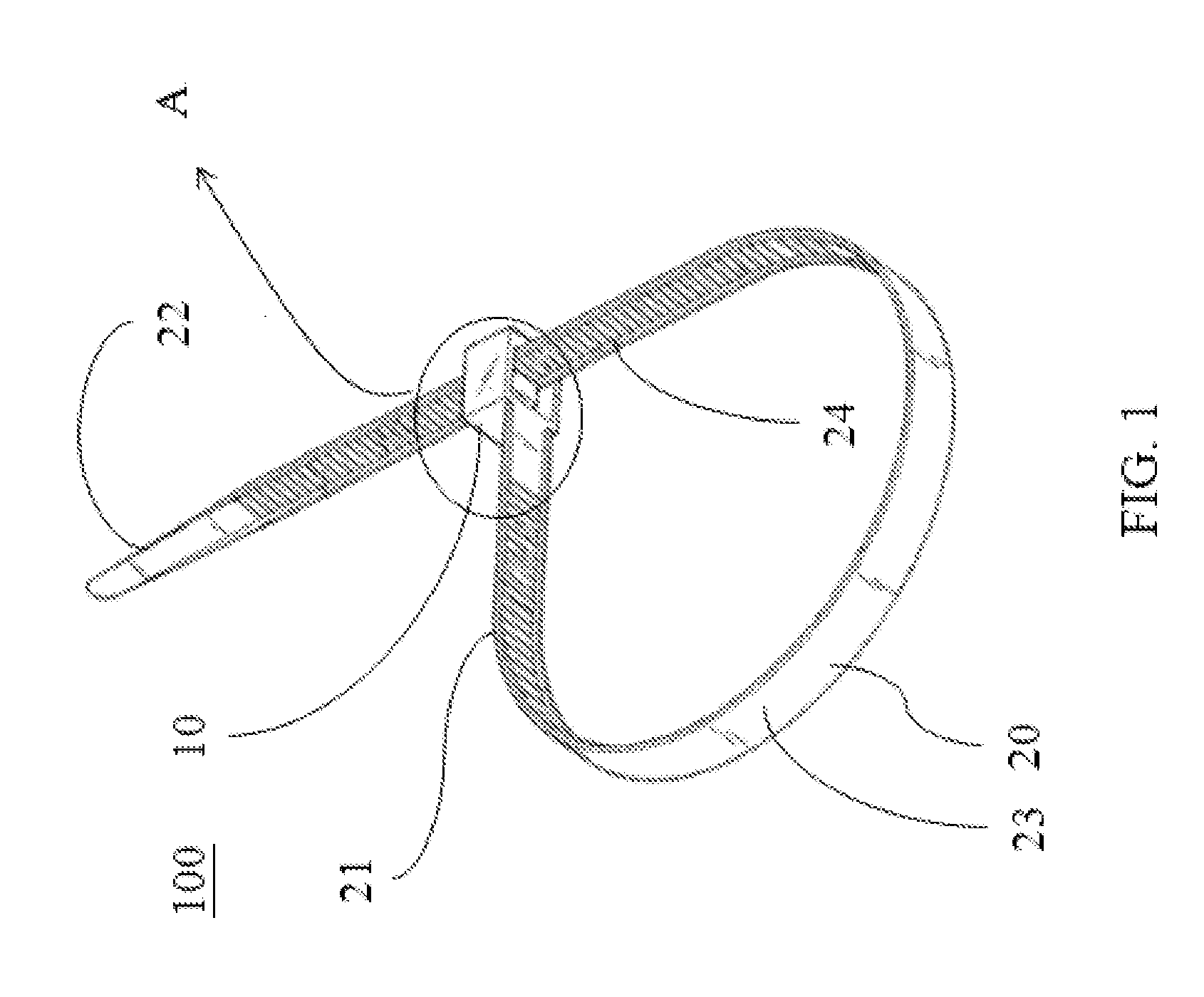

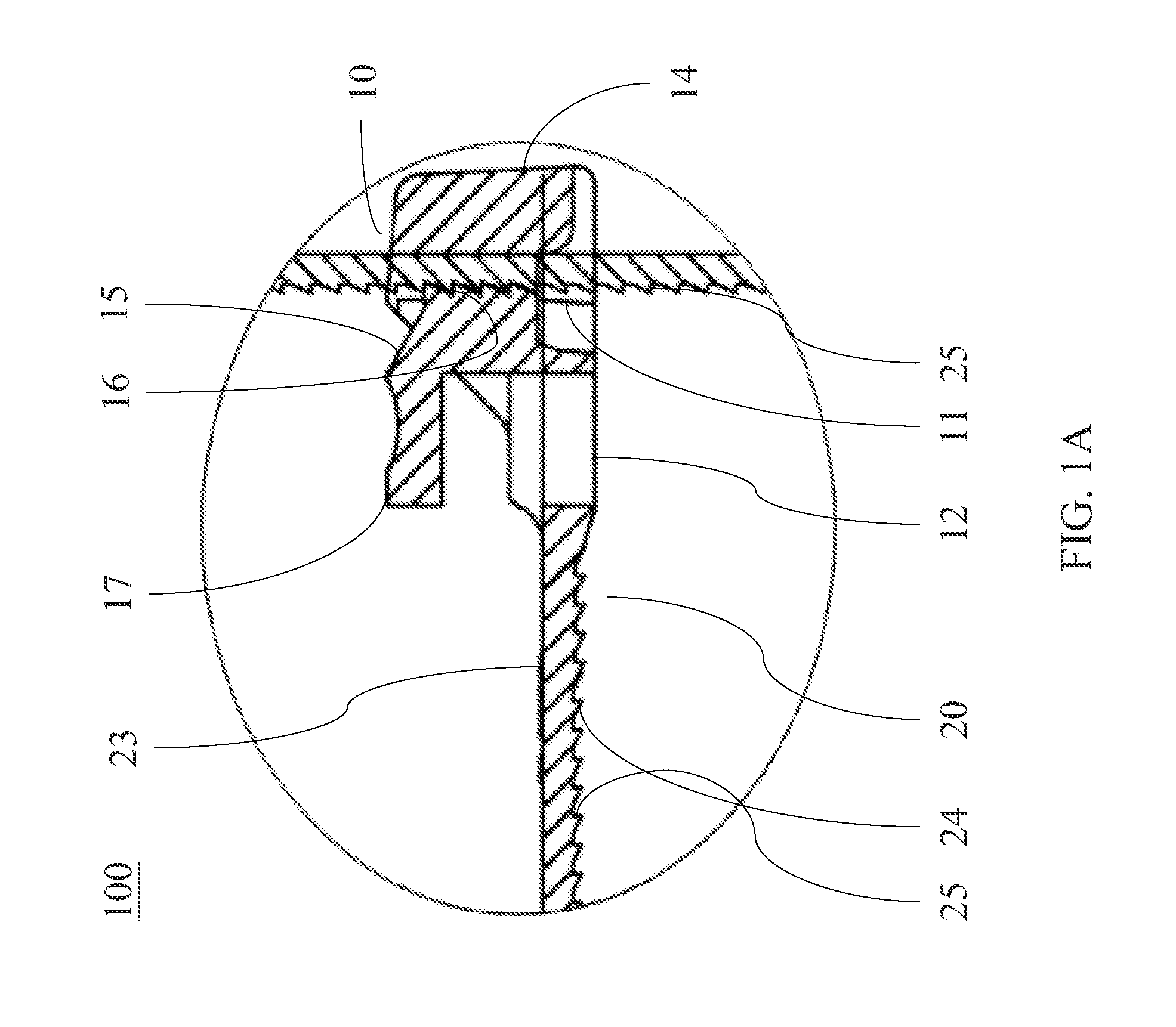

[0019]Referring to FIG. 1 and FIG. 1A, there are shown a perspective view of a releasable tie 100 in a preferred embodiment according to the present invention and an enlarged partial cross-sectional view of portion A shown in FIG. 1. As shown in the drawings, the releasable tie 100 comprises a locking element 10 and a band 20. The locking element 10 is formed with a window 11. The band 20 has a first end 21 and a second end 22. The first end 21 is connected to the locking element 10. The second end 22 penetrates the window 11 of the locking element 10 to fixedly engage the locking element 10, thereby bundling objects to be tied up.

[0020]Referring to FIG. 2, there is shown a perspective view of the releasable tie 100 in another preferred embodiment according to the present invention. The locking element 10 has a bottom plate 12, paired first walls 13, a second wall 14, and an operating rod 15. The bottom plate 12 has a front end 121 and a rear end 122. The first end 21 of the band 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com