Infant formula device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

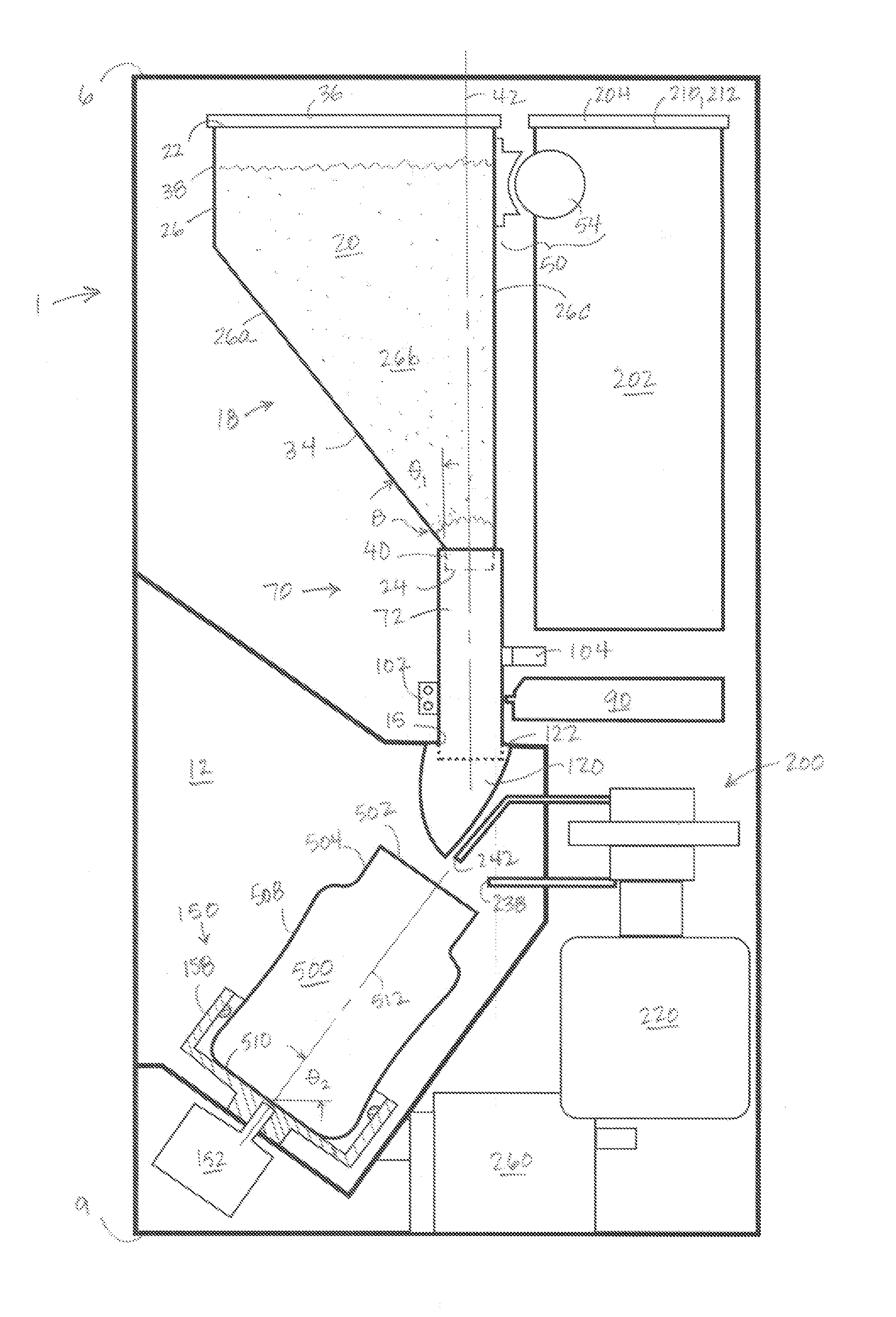

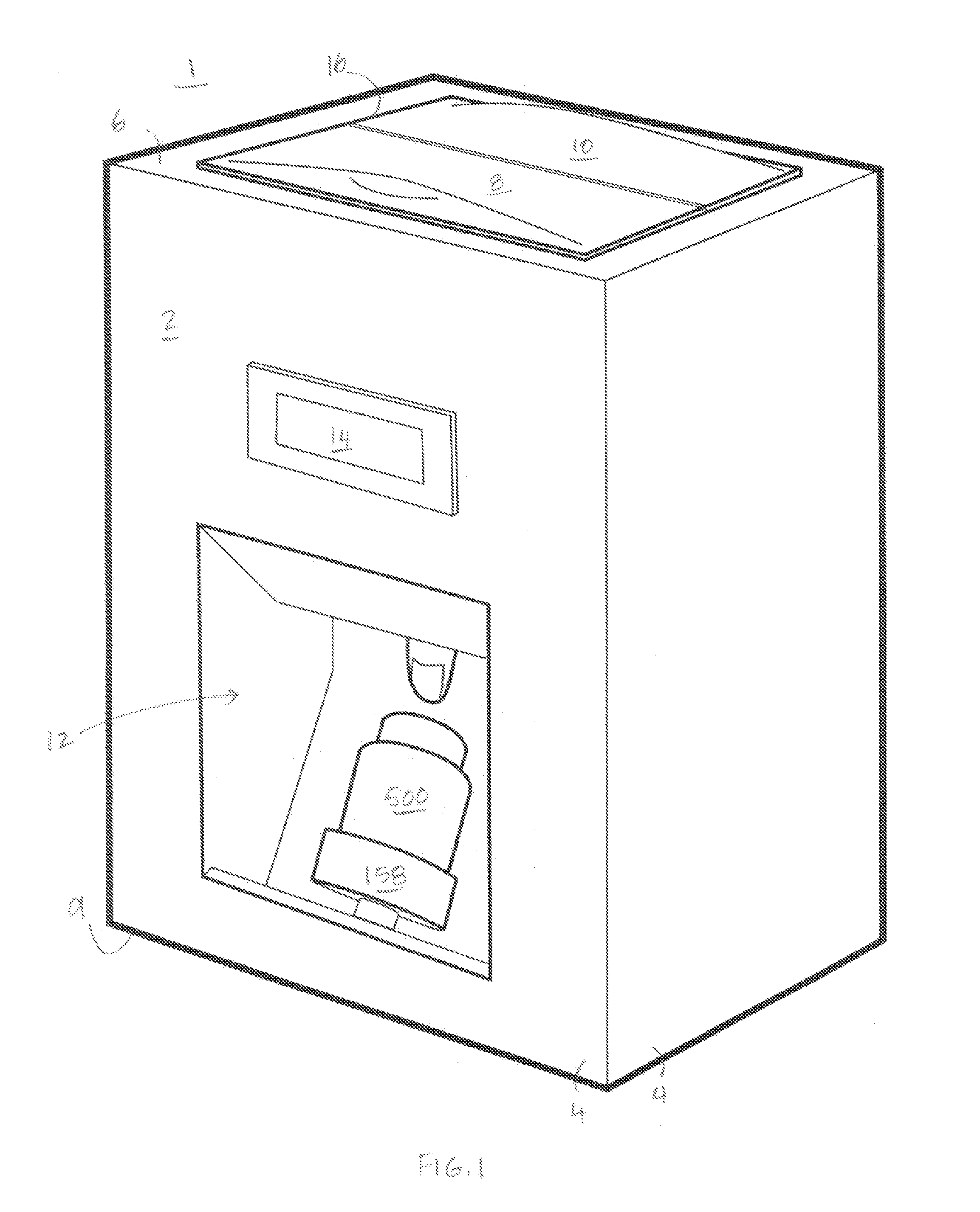

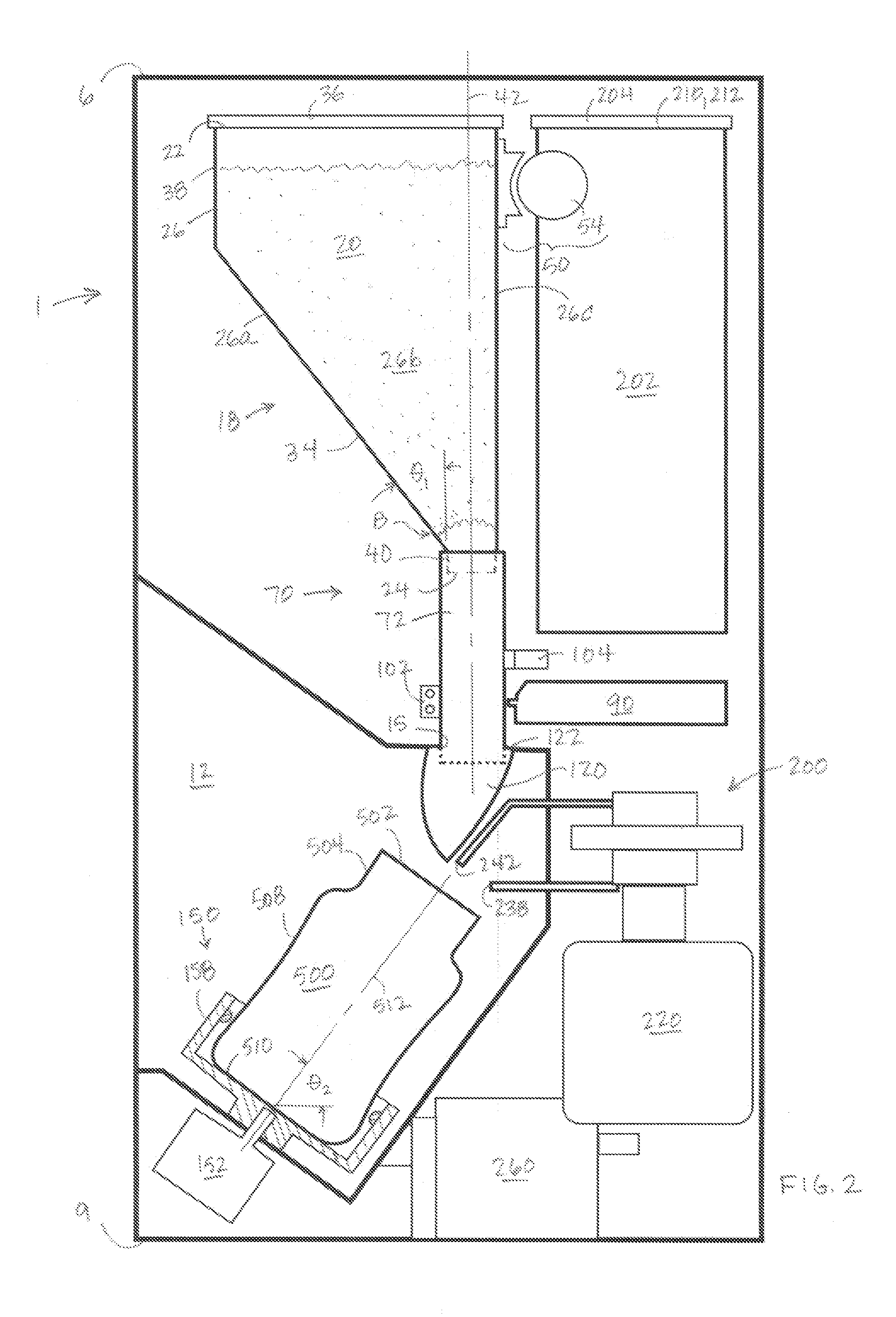

[0030]Referring now to FIGS. 1 and 2, the automated infant formula device 1 includes a hopper assembly 18, a dosing assembly 70, a dilution assembly 200, and a mixing assembly 150 enclosed within a housing 2. These assemblies 18, 70, 200, 150 are used to automatically prepare a reconstituted and pasteurized infant formula from a powder, and are described in detail below. The device 1 receives a serving container 500, such as a baby bottle, and is designed to dispense PIF and the dilution fluid (e.g. water) into the container 500, and then reconstitute and mix the PIF within the container 500.

[0031]The housing 2 includes sidewalls 4 and a closed top 6 and bottom 9 which provide a protective enclosure for the hopper, dosing, dilution and mixing assemblies 18, 70, 200, 150 therewithin. The top 6 of the housing 2 includes an opening 16 which is selectively opened and closed using hinged lid portions 8, 10. The lid portions 8, 10 can be lifted to provide access to the interior of the hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com