Vehicle securing structure

a technology for securing structures and vehicles, applied in couplings, instruments, manufacturing tools, etc., can solve the problems of adversely affecting the repeatability of tire force distribution and workload during vehicle testing, and achieve the effect of convenient inserting and repeatability of behavior

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

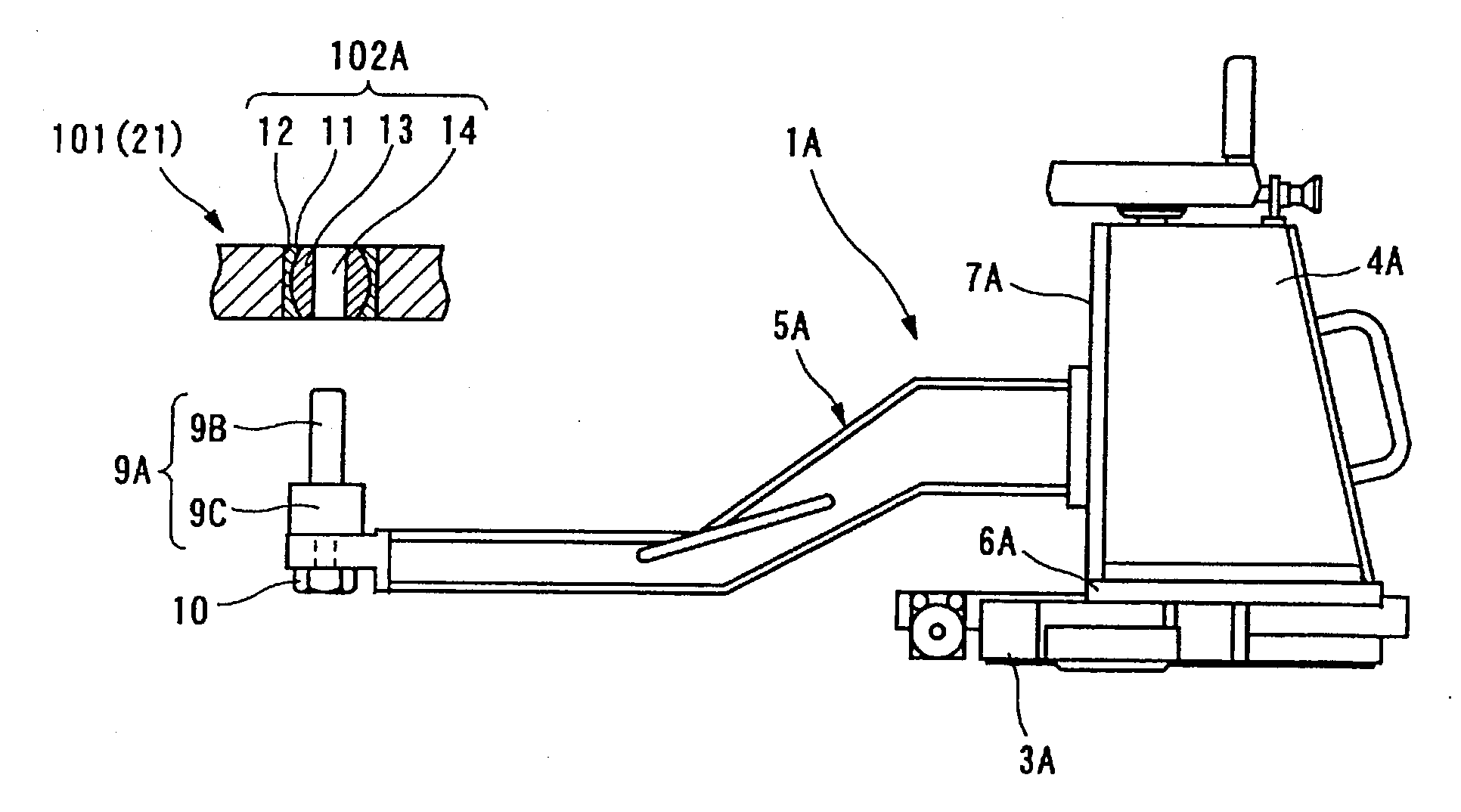

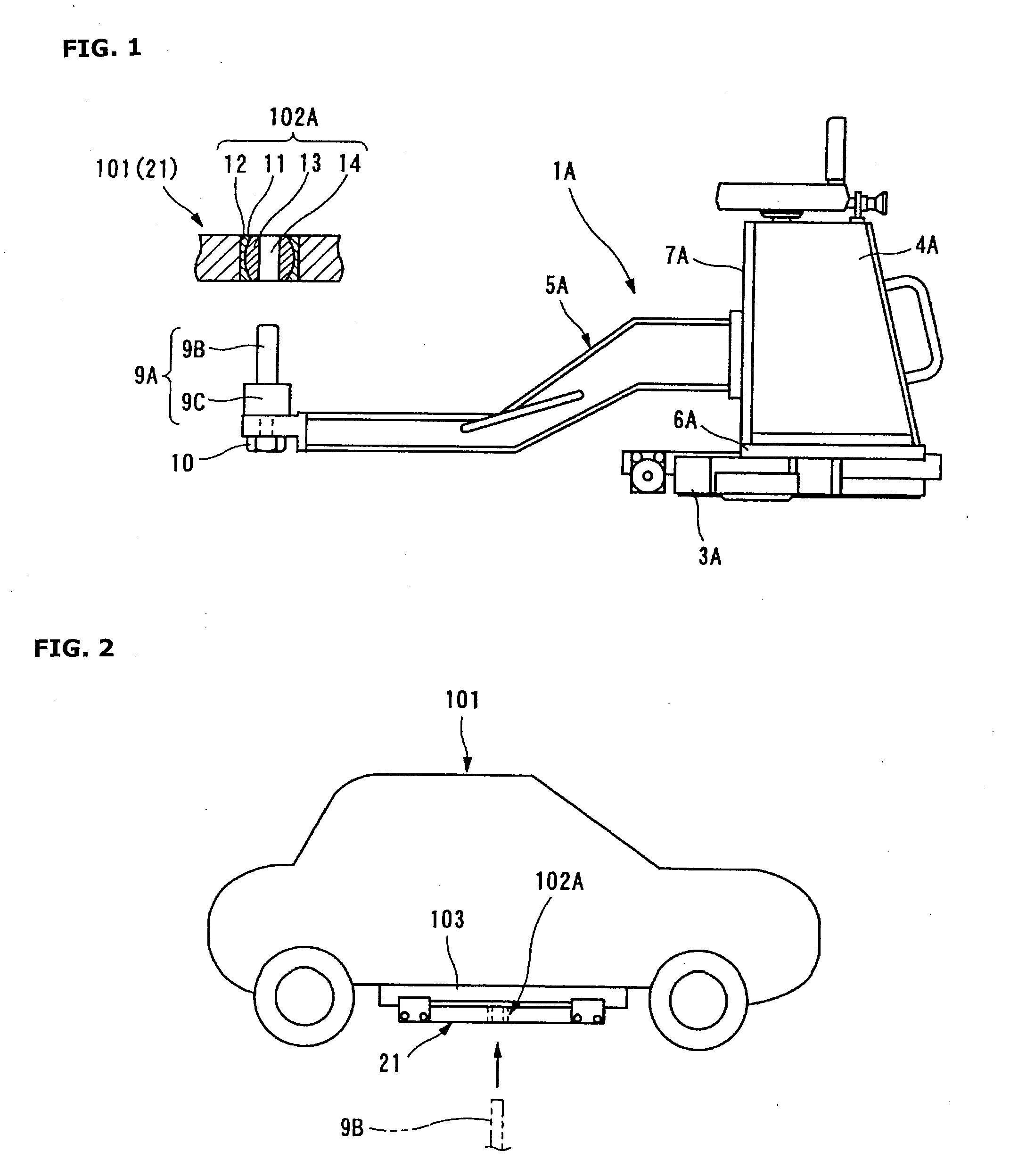

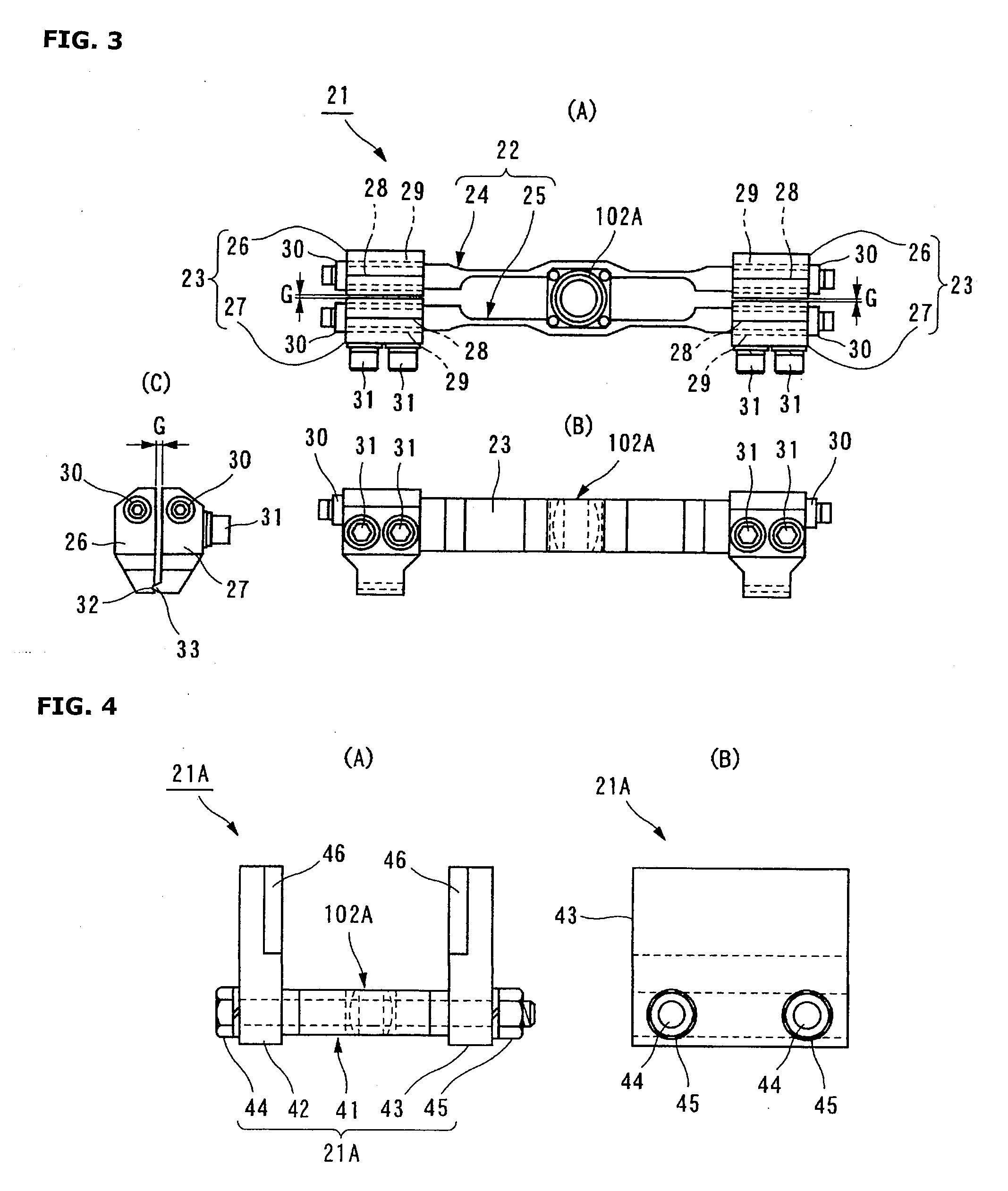

[0028]FIGS. 1 to 3 show a vehicle securing structure according to the present invention. As shown in FIG. 1, insertion of a linking adapter 9A of a vehicle securing device 1A into an adapter insertion part 102A provided in a test vehicle 101 secures the test vehicle 101.

[0029]The vehicle securing device 1A has a different outside shape from that of the vehicle securing device 1, which is described with reference to FIG. 6, but has a similar configuration as the vehicle securing device 1. The vehicle securing device 1A includes a device base part 3A, an arm support part 4A, and an arm part 5A, wherein the device base part 3A is provided in a test room and configured to slide along a rail 2A (not shown) in a longitudinal direction of the test vehicle 101, wherein the arm support part 4A is arranged on an upper surface side of the device base part 3A, and wherein the arm part 5A is cantilevered by the arm support part 4A.

[0030]The arm support part 4A is supported for sliding along a ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com