Slide rail device for vehicle seat

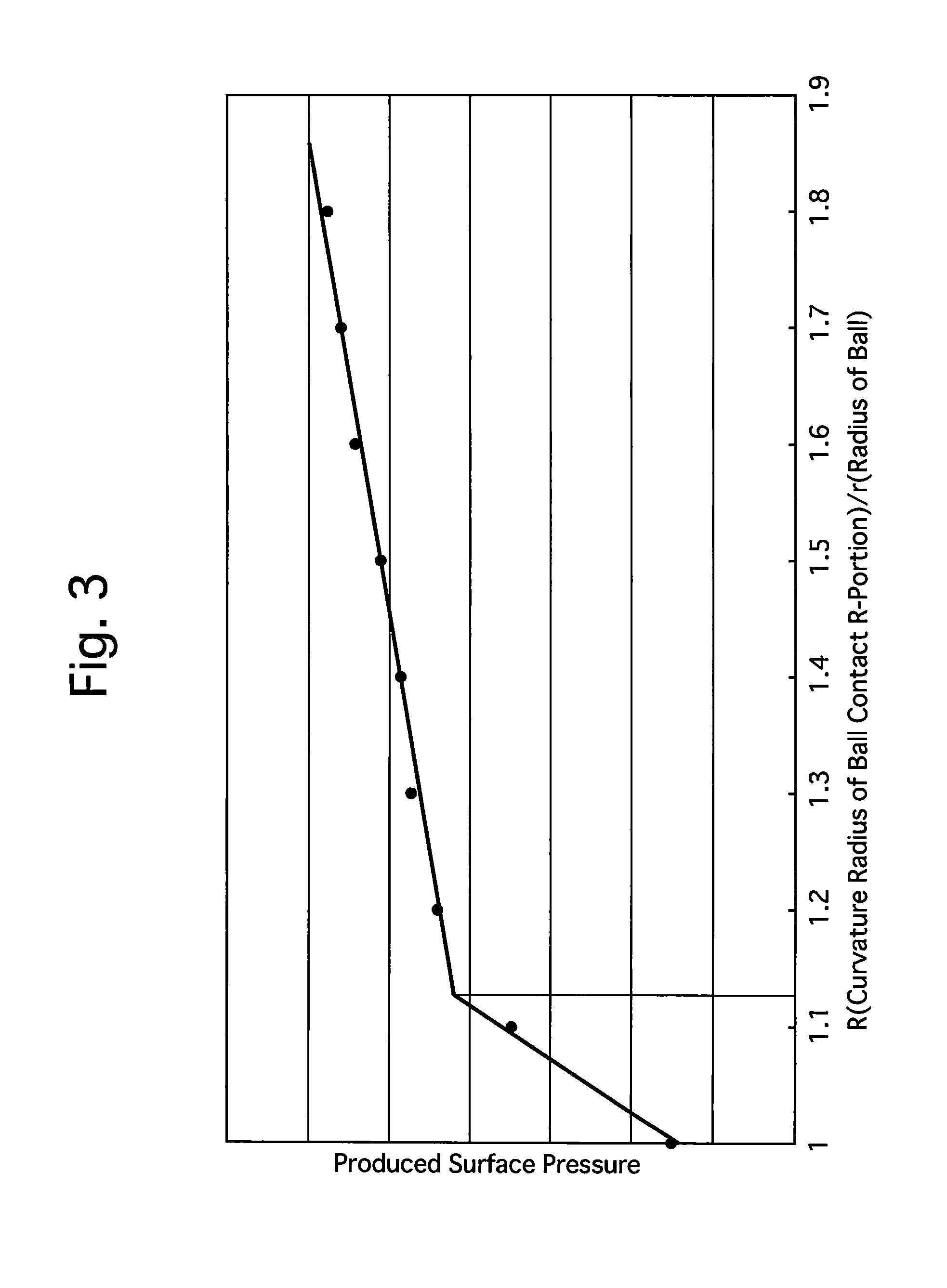

a technology for sliding rails and vehicle seats, which is applied in the direction of moving seats, machine supports, other domestic objects, etc., can solve the problems of unstable sliding operation of the upper rail and the lower rail, and the rollability of the balls can be deteriorated, and achieve the effect of high dimensional accuracy and hardness, and affecting the rollability of balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

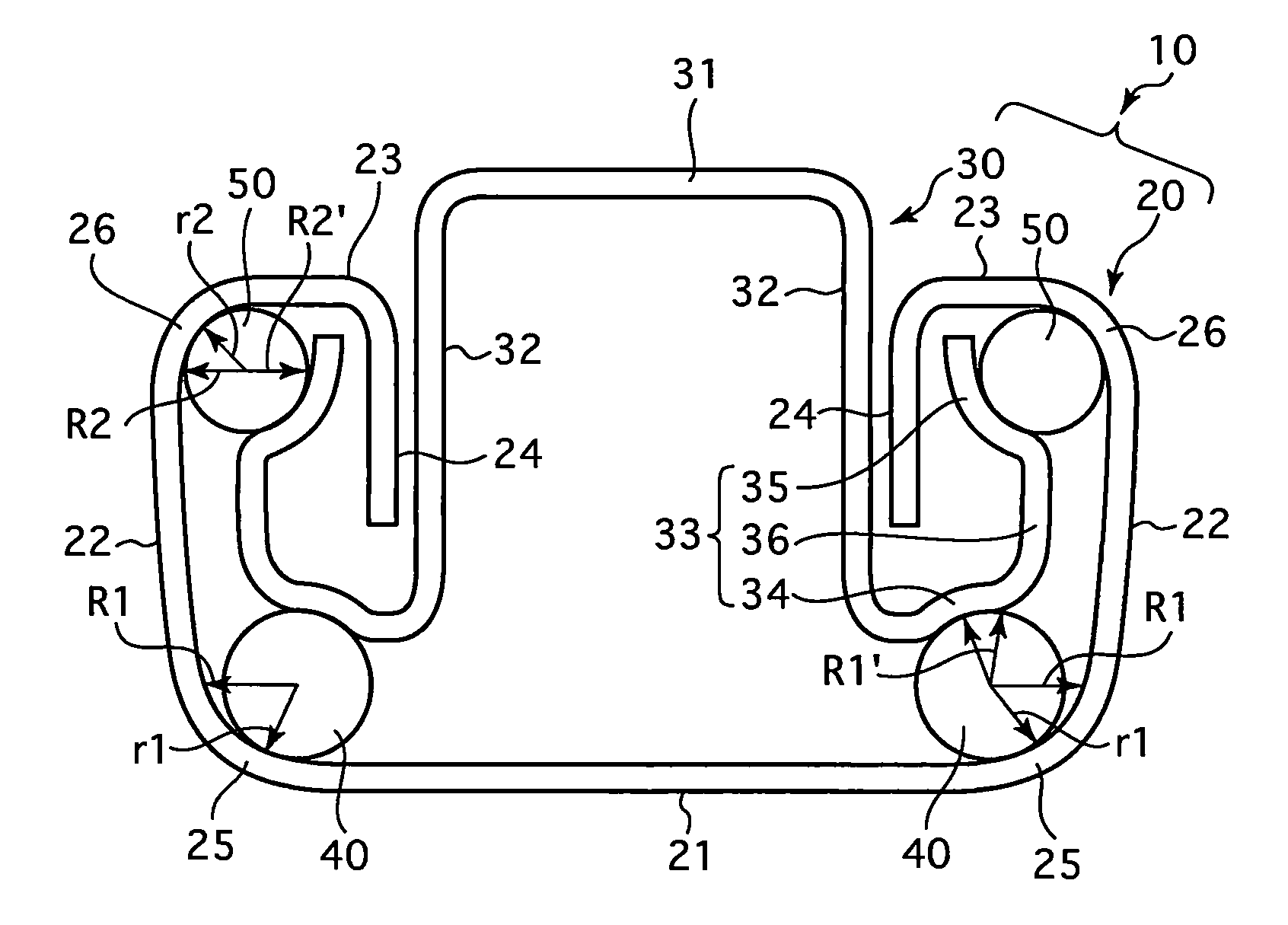

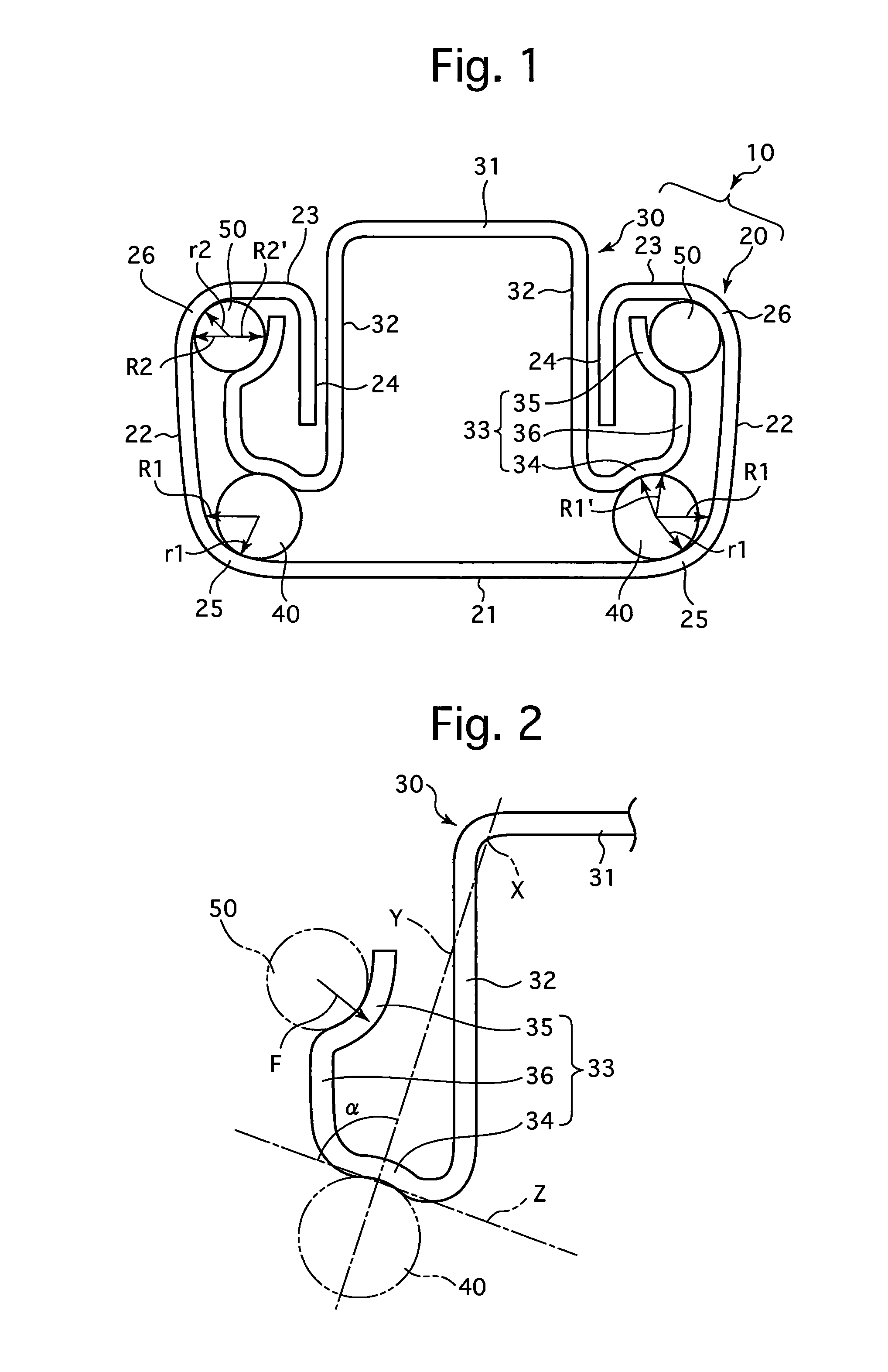

[0027]FIG. 1 shows an embodiment of a slide rail device 10 according to the present invention. The slide rail device 10 is provided with a lower rail 20 and an upper rail 30 which are fixed to a vehicle floor (not shown) and a vehicle seat (not shown), respectively, and is provided between the lower rail 20 and the upper rail 30 that are engaged with each other to be relatively slidable, with two types of steel balls, i.e., lower balls 40 and upper balls 50, which are installed between the lower rail 20 and the upper rail 30. The slide rail device 10 is bilaterally symmetrical in shape in a cross section taken along a plane normal to the extension direction (lengthwise direction) of the rails 20 and 30. The lower balls 40 are greater in diameter than the upper balls 50. As known in the art, two of the slide rail devices 10 are used as a pair (left and right slide rail devices) in a state of being fixed to a vehicle, and a lock mechanism and other components are installed to this pai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com