Headbox, sheet forming unit with a headbox and method for operating a sheet forming unit

a technology of sheet forming unit and headbox, which is applied in the field of headbox, can solve the problems of insufficient, and coarse cloud formation inside the fibrous stock suspension, and achieve the effects of reducing production costs, short construction of units, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

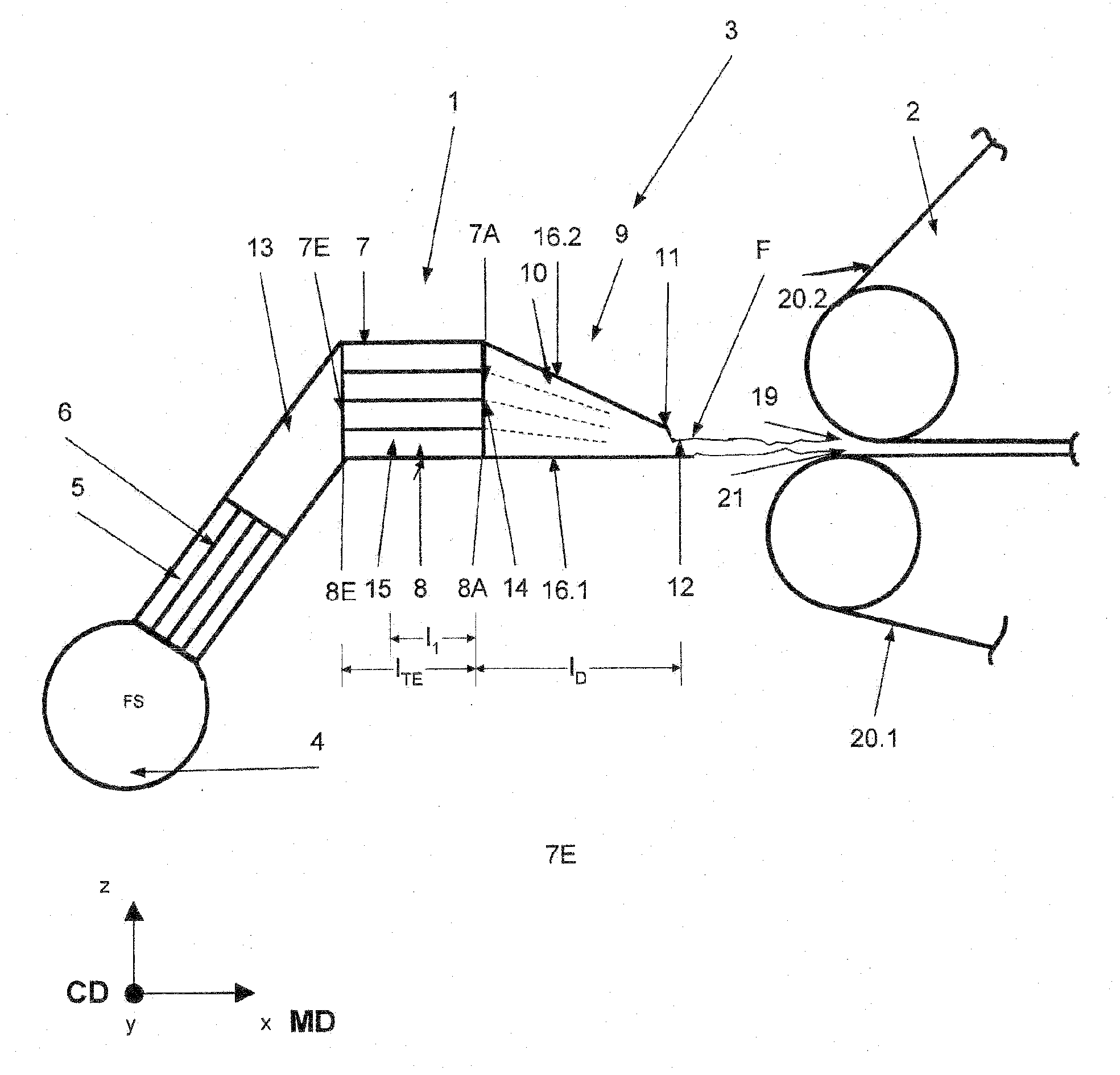

Embodiment Construction

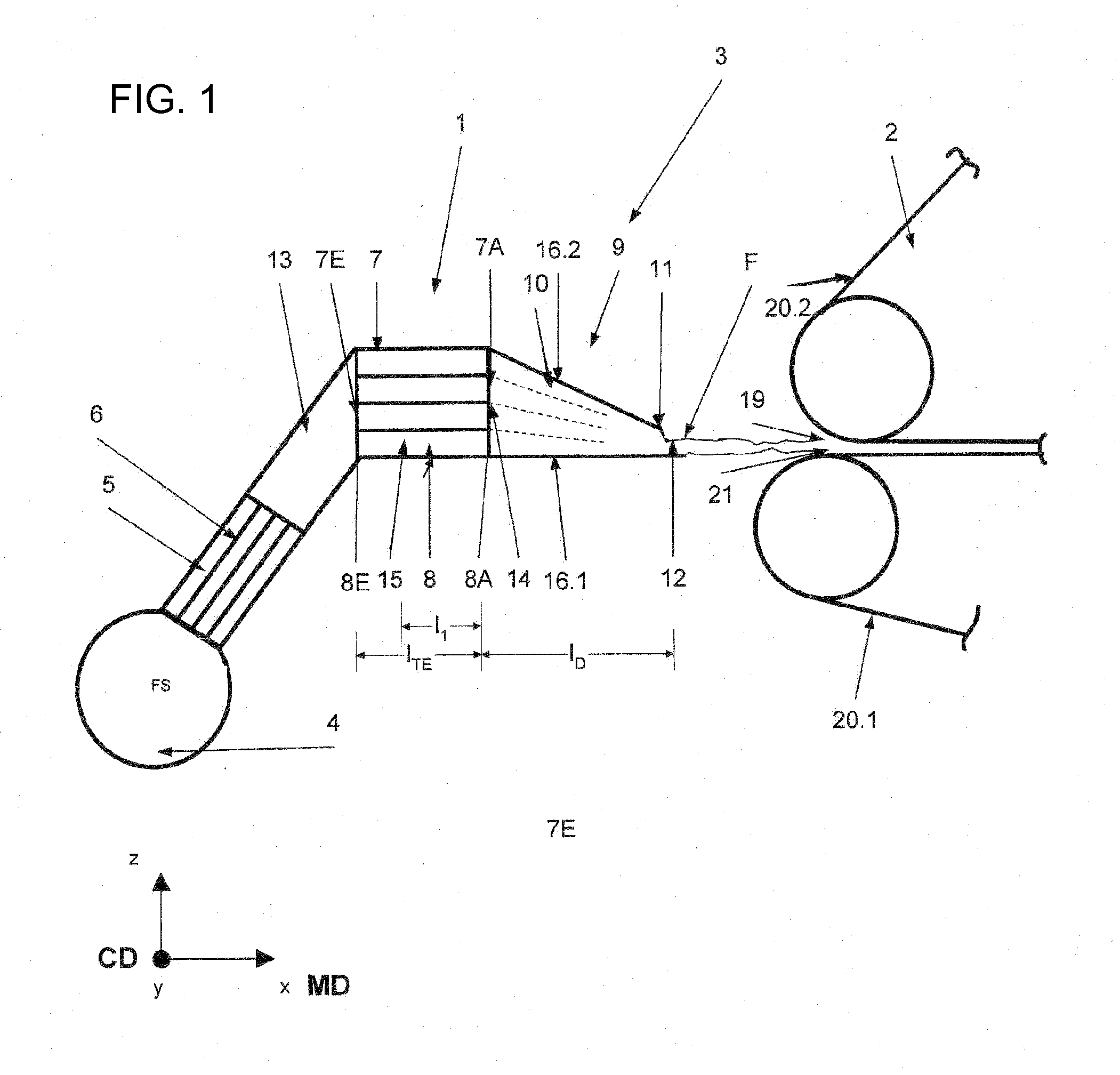

[0050]FIG. 2 clarifies in a schematically simplified illustration of a diagram the influence of the level of stock consistency SK inside a fibrous stock suspension FS upon the formation. For this purpose the formation of the flake structure FL in the free jet in regard to the dimension of the forming flakes is plotted above stock consistency SK. From this the connection can be seen between high stock consistency SK and an uneven and coarsely clouded formation in regard to the arrangement of the fibers and fillers based on increased fiber flocculation, that is the tendency in conventional known headboxes toward larger flakes in the free jet F of fibrous stock suspension being delivered from the outlet gap of a headbox. It can also be seen that with fibrous stock suspensions with lower stock consistency—in this example below a stock consistency parameter SKx of 1.2%—the flake formation is less, meaning that only smaller flakes are observed in the free jet at the discharge from the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com