Low maintenance condenser

a condenser coil, low-maintenance technology, applied in the direction of corrosion prevention, stationary conduit assembly, lighting and heating apparatus, etc., can solve the problems of increasing the operative pressure, increasing the energy consumption of components, and reducing the useful life of components, so as to reduce or eliminate the necessity of maintenance, prolong the maintenance interval, and reduce the effect of maintenan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

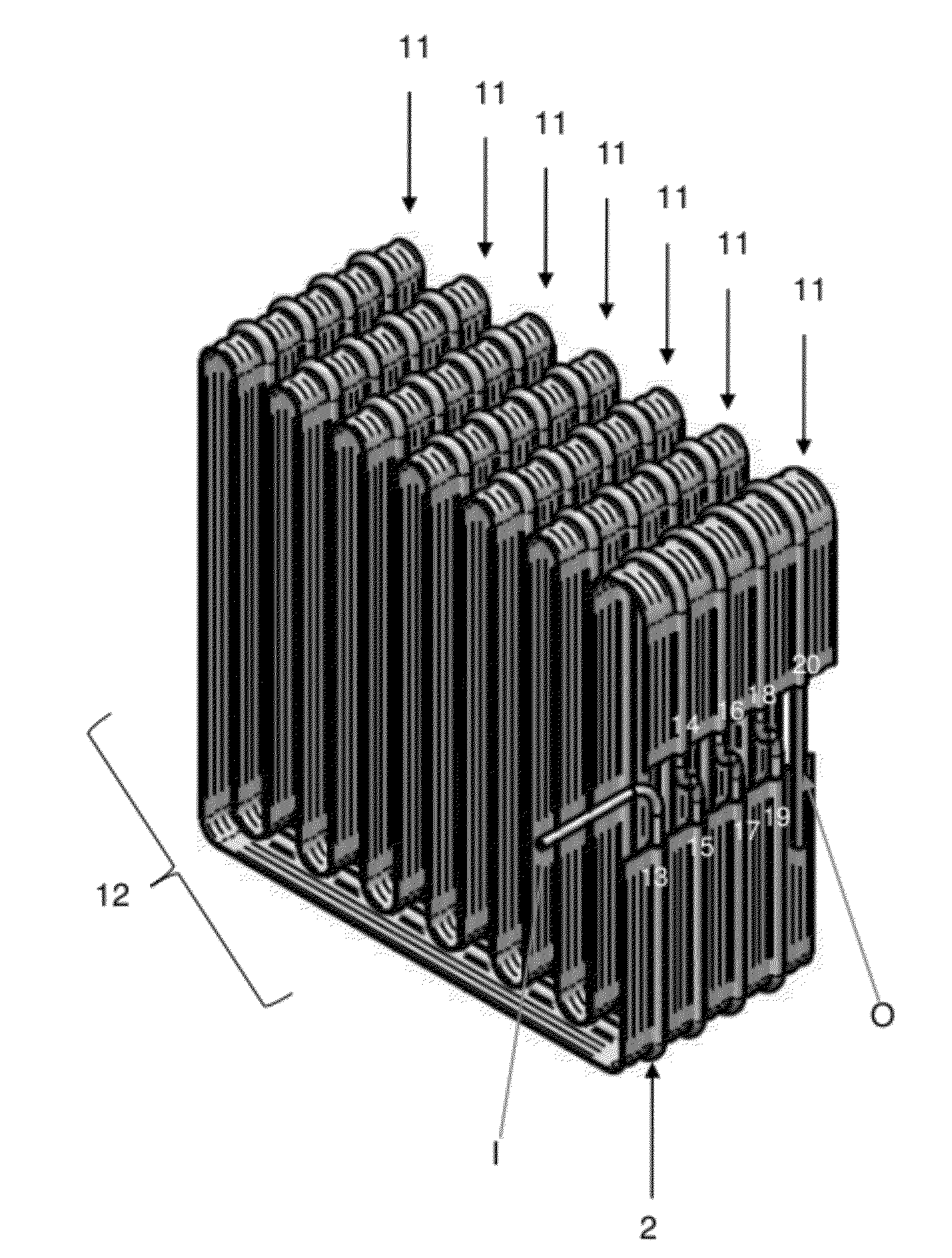

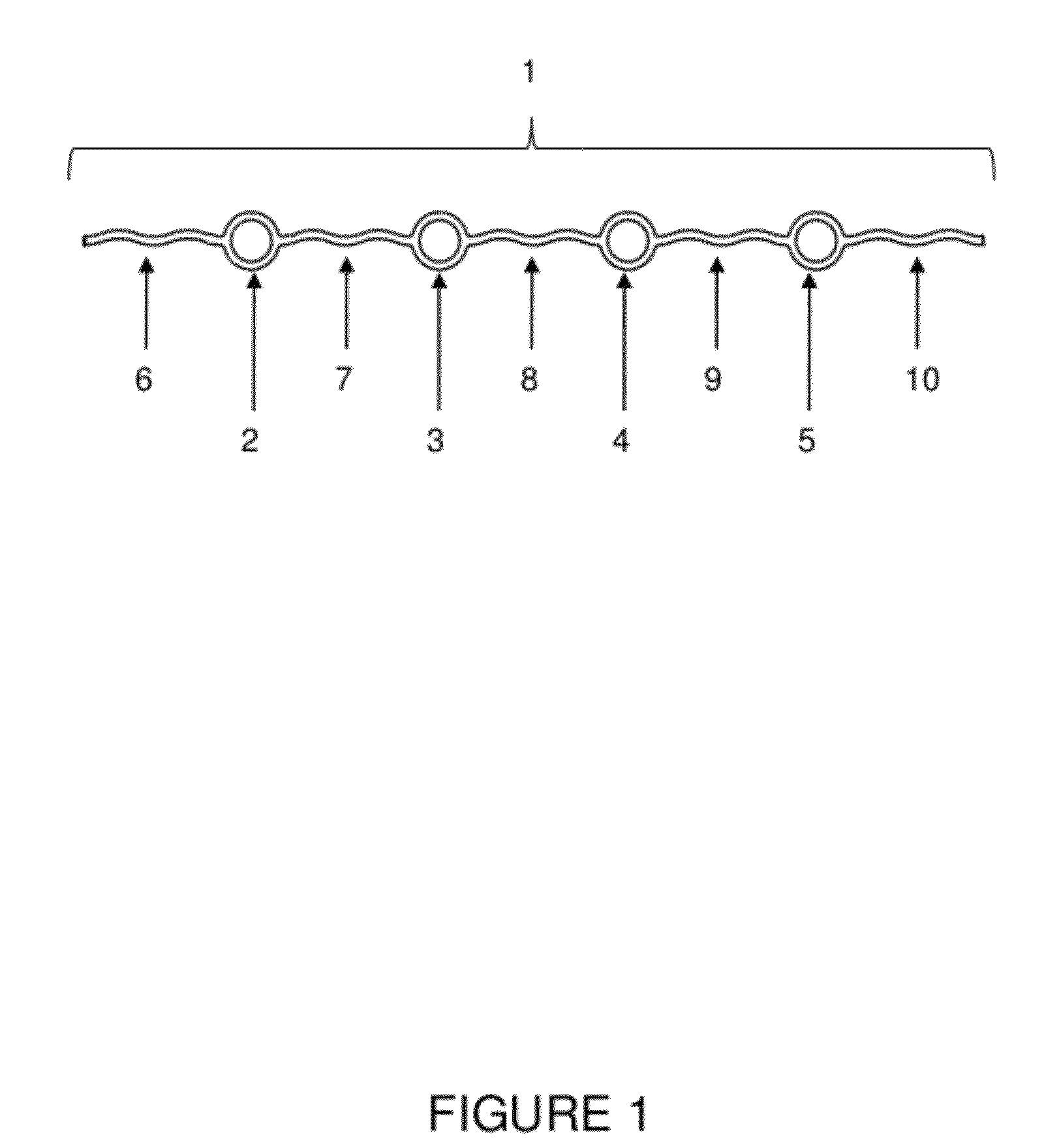

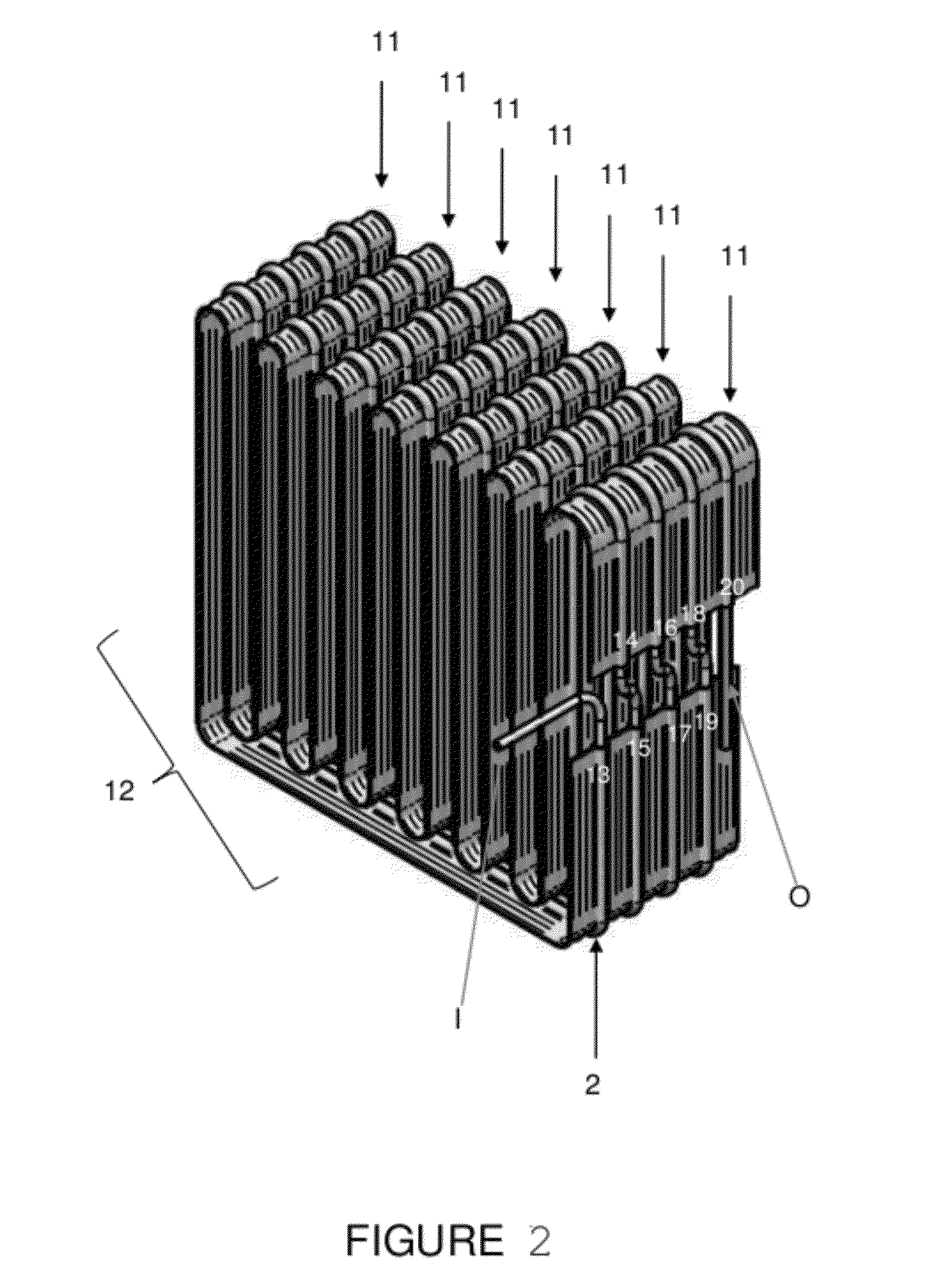

[0025]The low maintenance condenser for commercial refrigeration systems of the present invention will be described with reference to the accompanying drawings, using reference numbers to identify the constitutive parts of the condenser, shown in the drawings which illustrate the preferred embodiments of the invention.

[0026]The low maintenance condenser of the present invention comprising:

[0027]a single metallic flat section comprising:[0028]one or more pipes integrally formed in the flat section, for the flowing of a refrigerant gas, each pipe being equidistantly located parallel to each other, each extending along the length of the flat section of extruded aluminum, and each having a first and a second end, each pipe being integrally formed in the flat section of extruded aluminum;[0029]a flat longitudinal heat dissipating section at each side of each pipe, each flat longitudinal heat dissipating section having the same width;

[0030]said single flat section is plied or rolled, form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| interior diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com