Rolled medium holder device and recording apparatus

a technology of holder device and holder device, which is applied in the direction of function indicators, thin material processing, printing, etc., can solve the problems of deformation, damage to the guide portion, and scratching of the area where the tips of the screws make contact,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

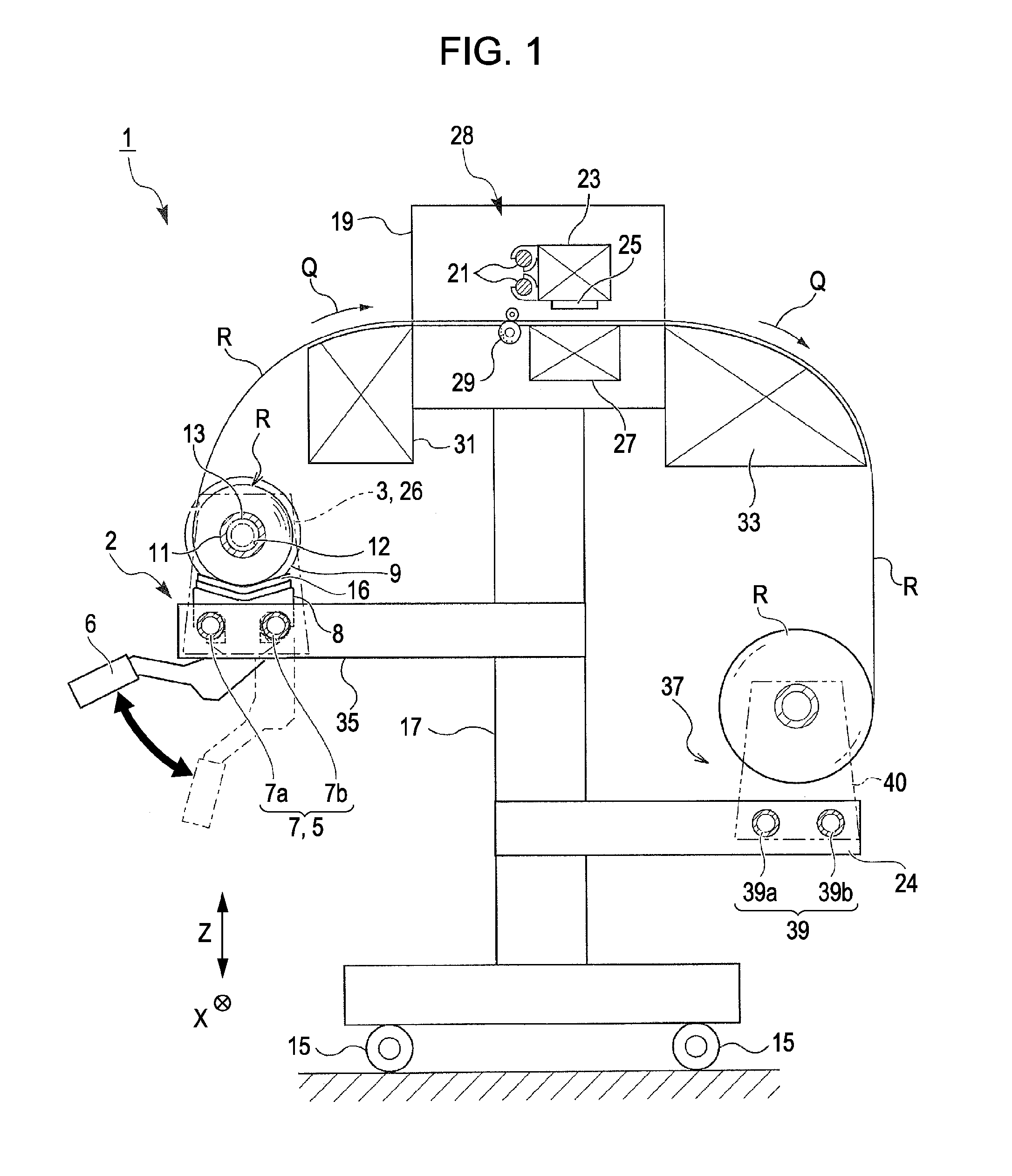

[0033]Hereinafter, embodiments of the invention will be described with reference to the drawings.

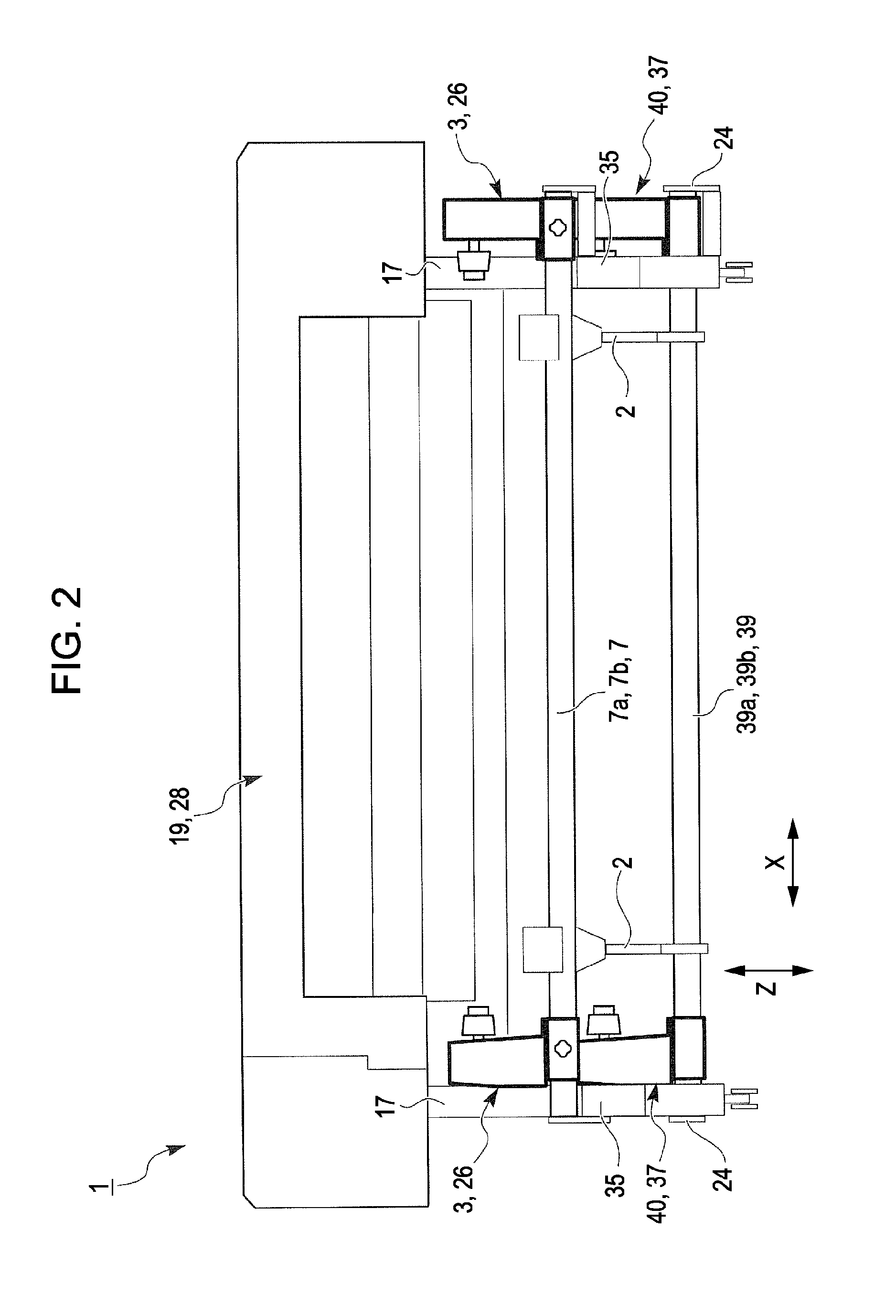

[0034]FIG. 1 is a cross-sectional view, seen from the side, illustrating an outline of the overall configuration of a large-format ink jet printer 1 (called simply a “printer” hereinafter), serving as a recording apparatus according to this embodiment.

[0035]As shown in FIG. 1, the printer 1 includes a medium feed-out mechanism 26, a recording unit 28, and a take-up mechanism 37. Of these, the medium feed-out mechanism 26 is configured so as to be capable of releasing a rolled medium R, which is wound up in roll form, and feeding that rolled medium R in a feed direction Q. Specifically, the medium feed-out mechanism 26 includes first holder units 3 and a roller pair 29.

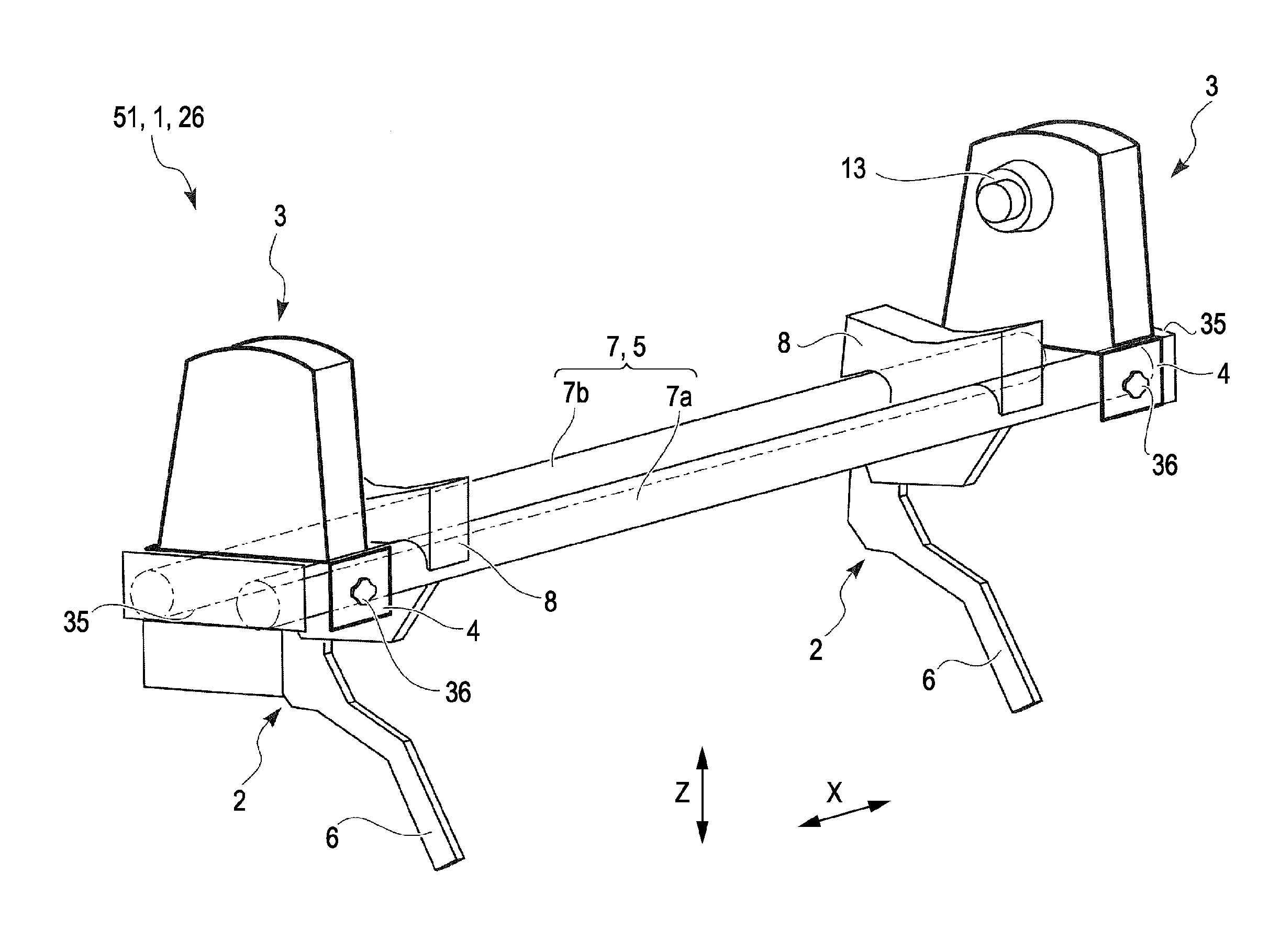

[0036]Of these, the first holder units 3 are provided so as to be capable of holding both ends of the rolled medium R so that the rolled medium R can rotate. Each of the first holder units 3 includes a shaft portion 13 that...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Force | aaaaa | aaaaa |

| Flexibility | aaaaa | aaaaa |

| Shape | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com