Method and apparatus for manufacturing a bullet charged with compressible composite explosives

a composite explosive and compressible technology, applied in the direction of weapons, projectiles, ammunition, etc., can solve the problems of high explosion probability, high resistance of conventional explosives, and limited application of compressible composite explosives to small caliber bullets, so as to achieve safe and uniform production of bullets in large scal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The method for manufacturing a bullet charged with compressible composite explosives according to the present invention will be described in more detail with reference to the drawings attached.

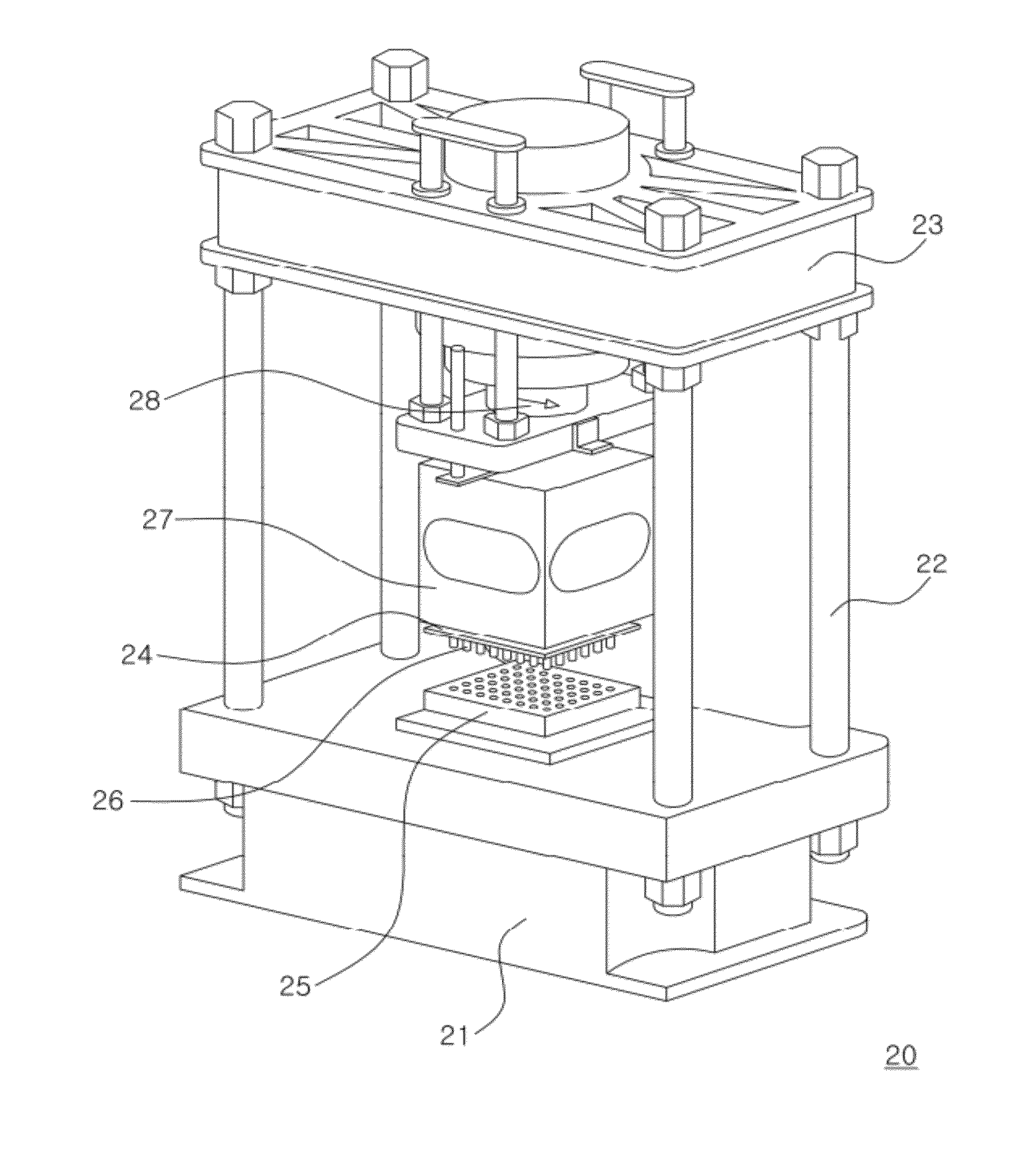

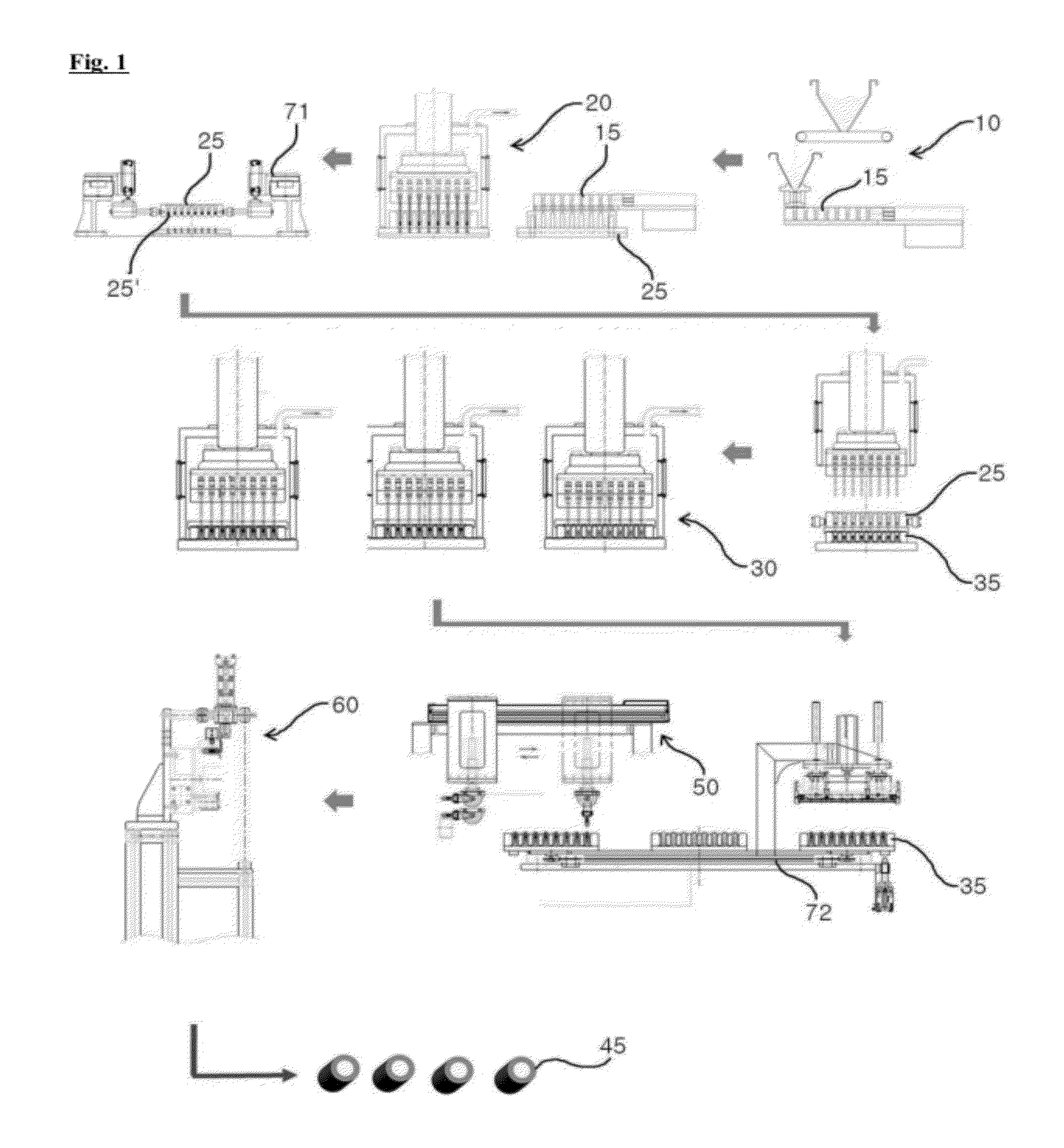

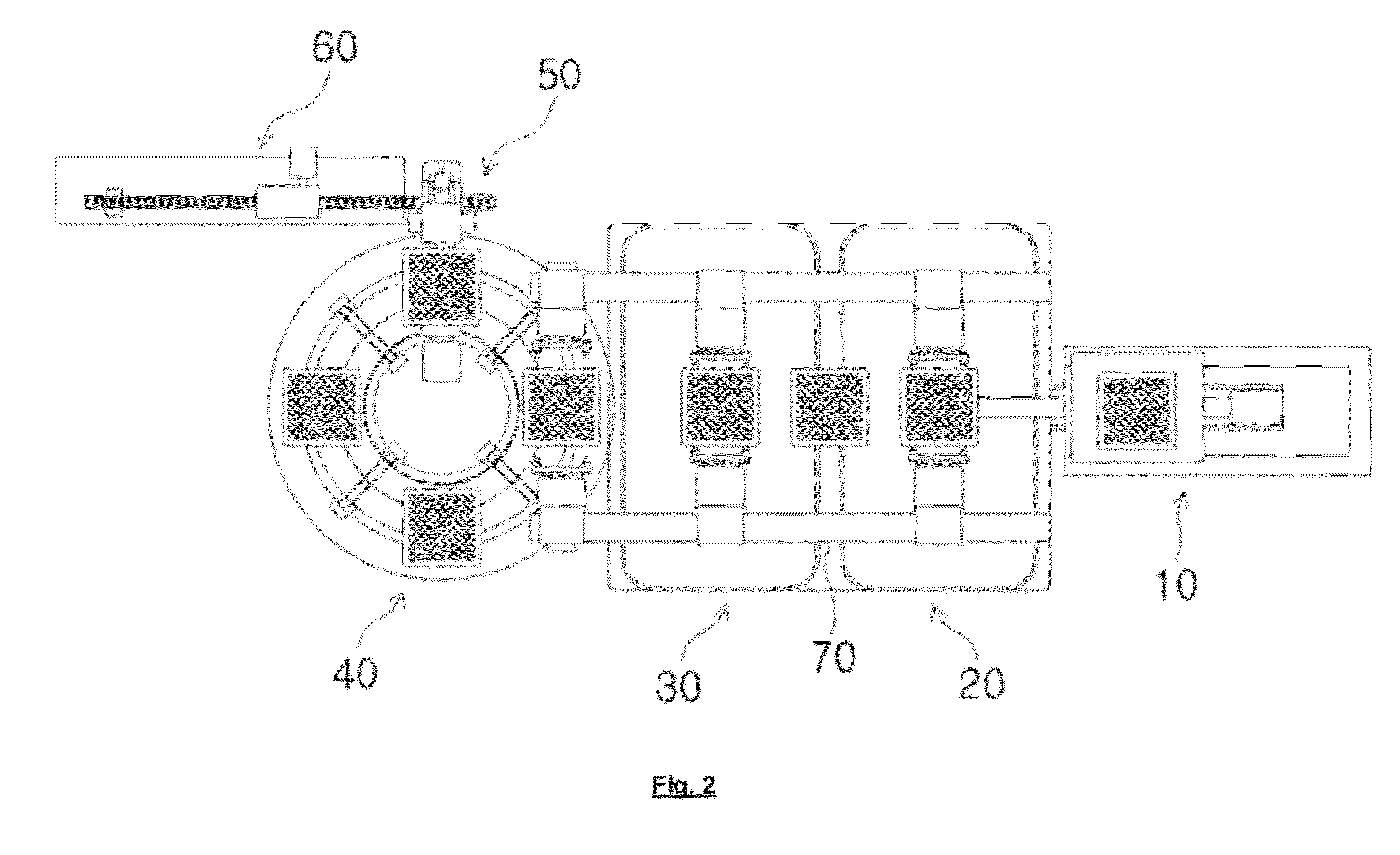

[0047]The method for manufacturing a bullet charged with compressible composite explosives according to the present invention, as shown in FIG. 1, comprises: a first process in which particle explosives is measured in constant amount by using a particle explosives constant quantity supplying device 10 and is charged to a pallette mold 15, a second process in which the particle explosives is transferred to a pellet-forming mold 25 by transporting the pallette mold 15 charged with the particle explosives to the constant pressure molding device 20, and returned to the particle explosives constant quantity supplying device 10, and then the particle explosives of the pellet-forming mold 25 is molded under constant pressure to a pellet, a third process in which the pellet-forming mold 25 is tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

| weight | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com