Rapid Deployment, Self-Inflating, Interlocking, Modular Flood-Water Barrier Wall System

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

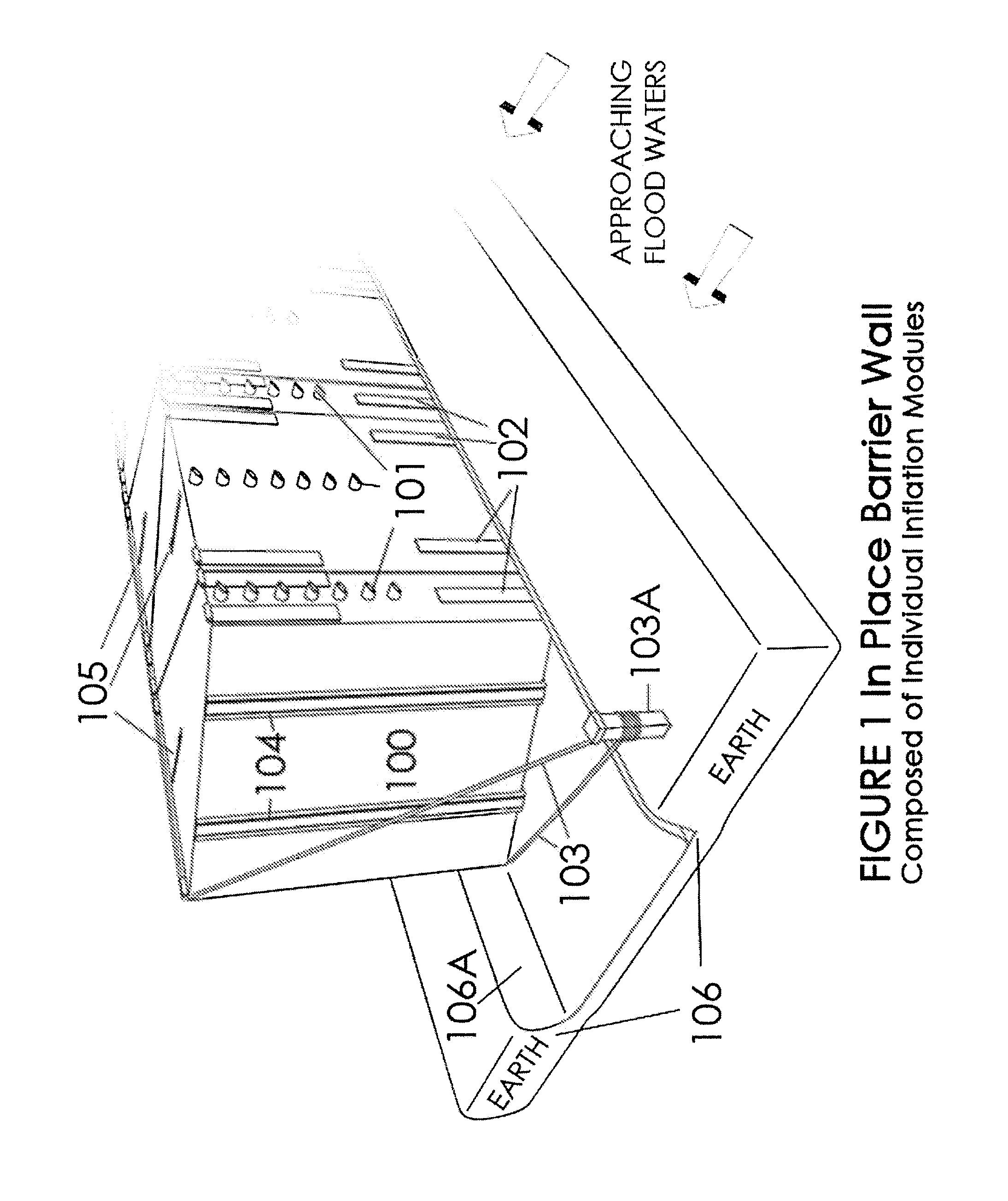

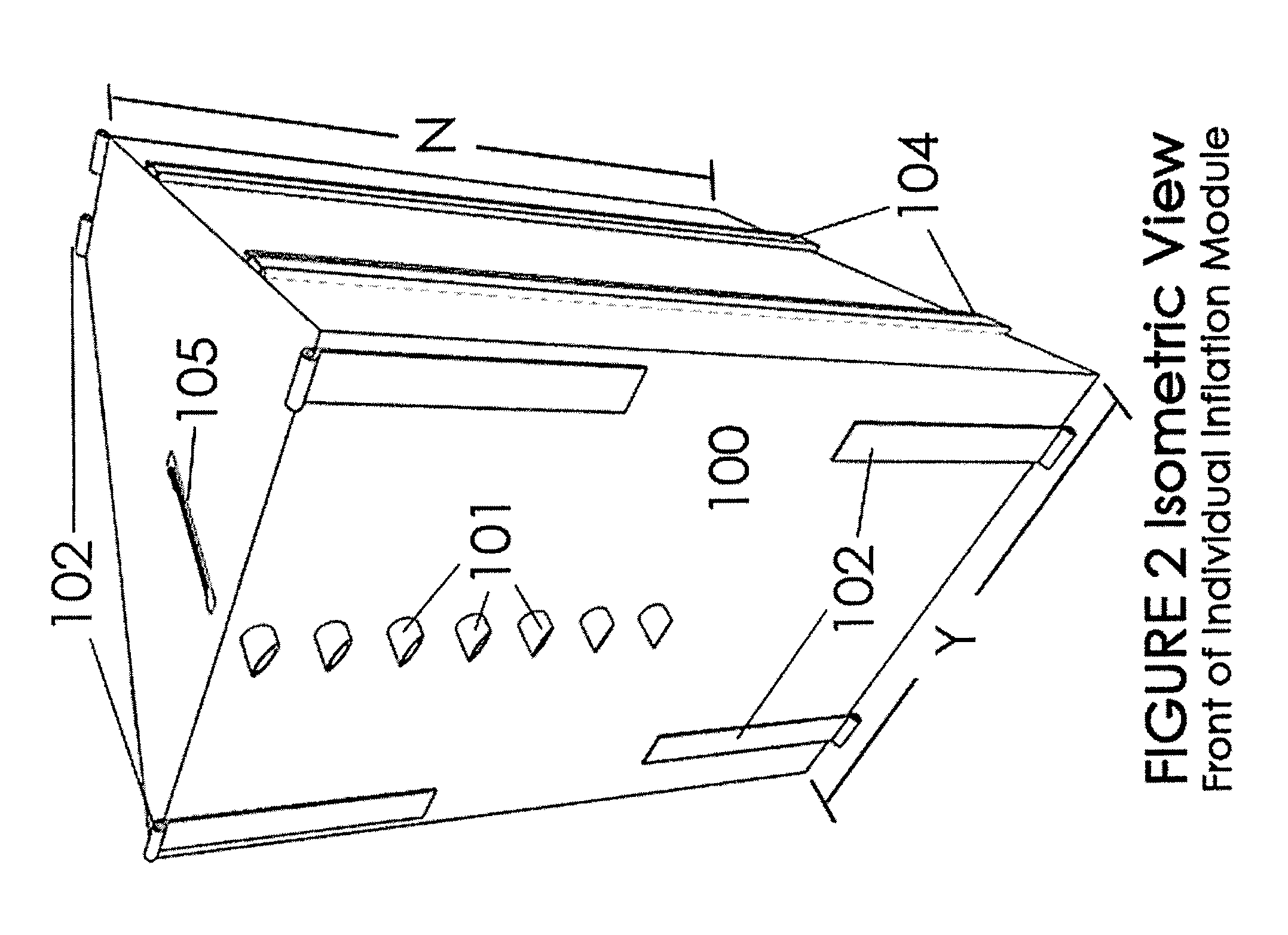

[0043]Referring now to the drawings there is illustrated in FIGS. 1-7, Inflation Modules 100. These Modules are the primary building blocks of the barrier wall and are made from a flexible container or bag. These bags are preferably are made of woven natural or man-made materials such as polypropylene. In the illustrated embodiment, the material is 6-9 oz. tightly woven polypropylene treated for a minimum of 1,600 hours of UV resistance and produced in solid black with orange web strapping and side seals. The Module measures approximately 48″ across the front, 12″ across the back and with equal sides measuring approximately 48″. The Module has a carrying capacity ranging from 3,000 lbs. to 6,000 lbs. with as much as a 500% safety factor. Depending upon the selected outside dimensions of the Module, the typical bag will hold between 40 and 60 cubic feet of hydrated cellulose / polymers.

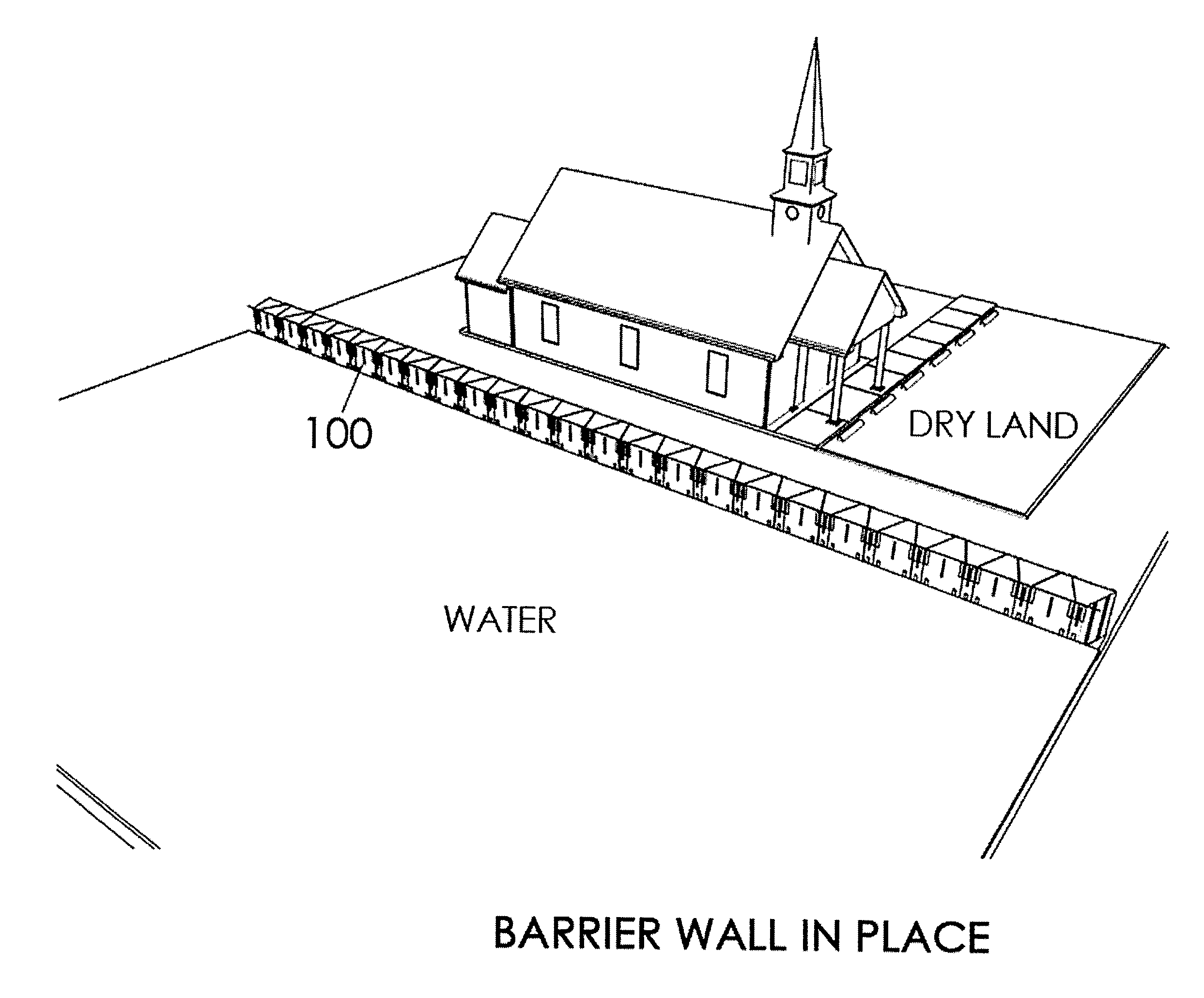

[0044]Typically a single string of Modules arranged side by side, and placed alternating front-back a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com