Novel Improvements for KRISS-type Firearm and Magazines for these Firearms

a technology of kriss-type firearms and magazines, which is applied in the direction of weapons, firing/trigger mechanisms, ammunition loading, etc., can solve the problems of vibrating and falling out of magazines well, and achieve the effect of efficient us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

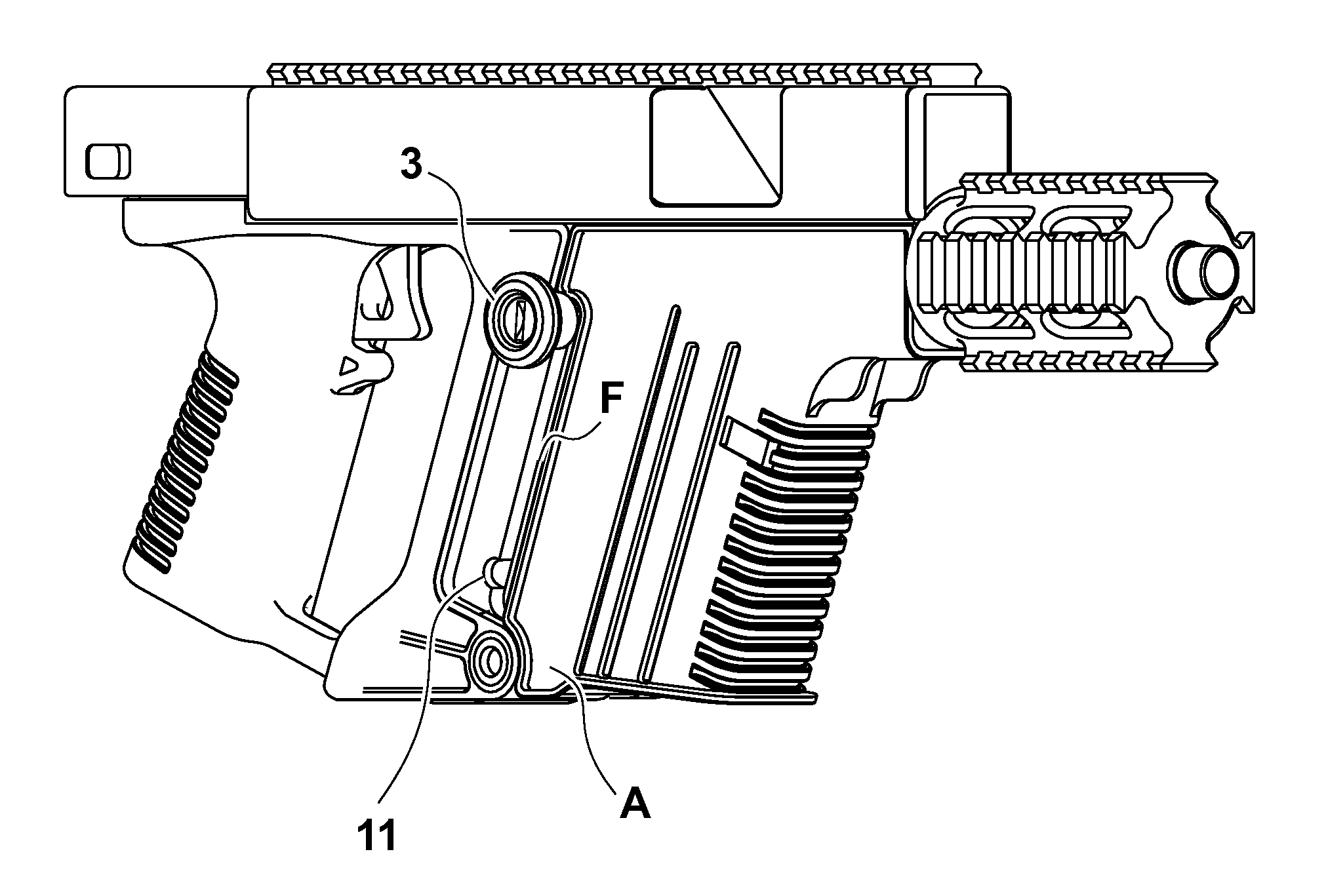

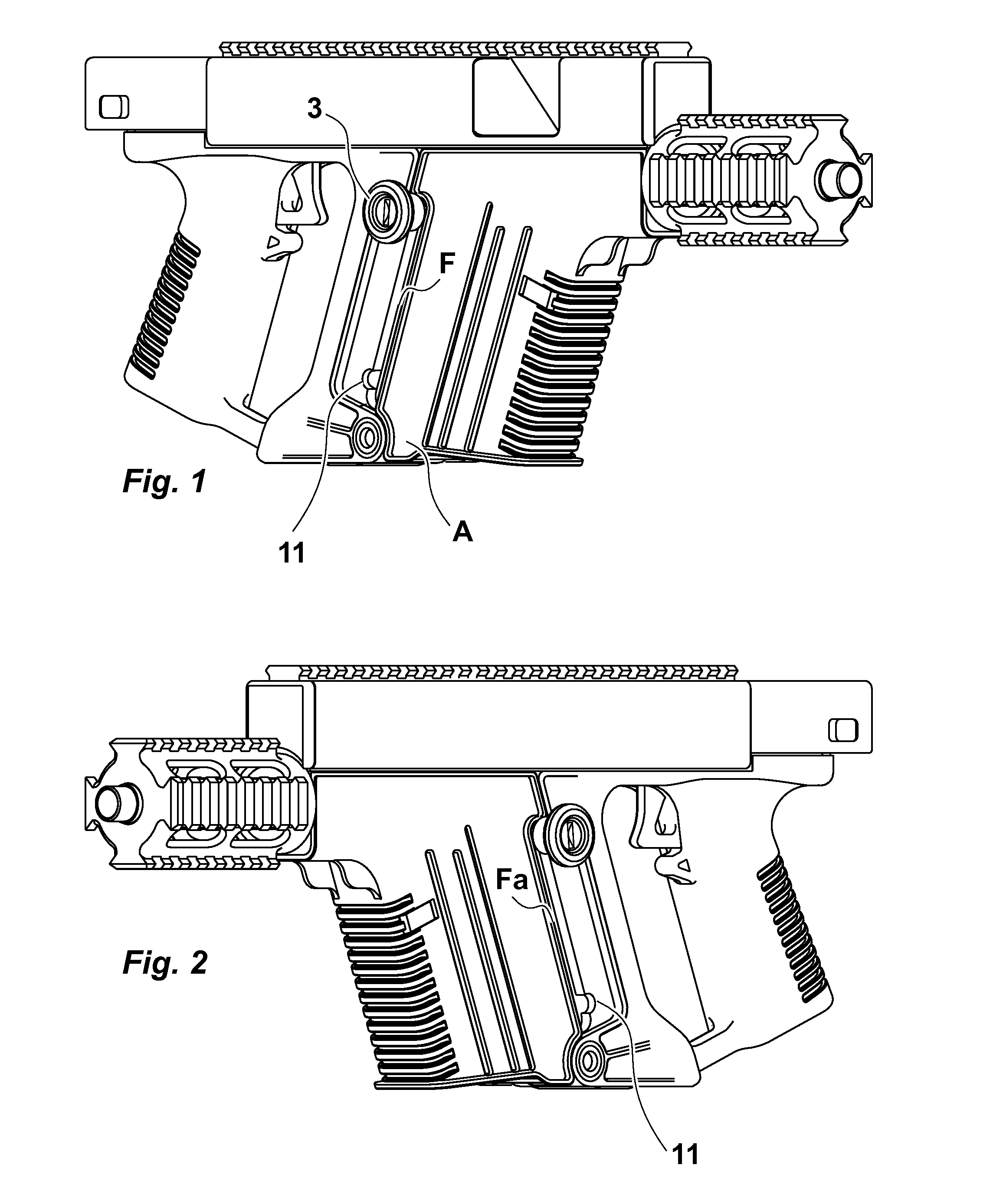

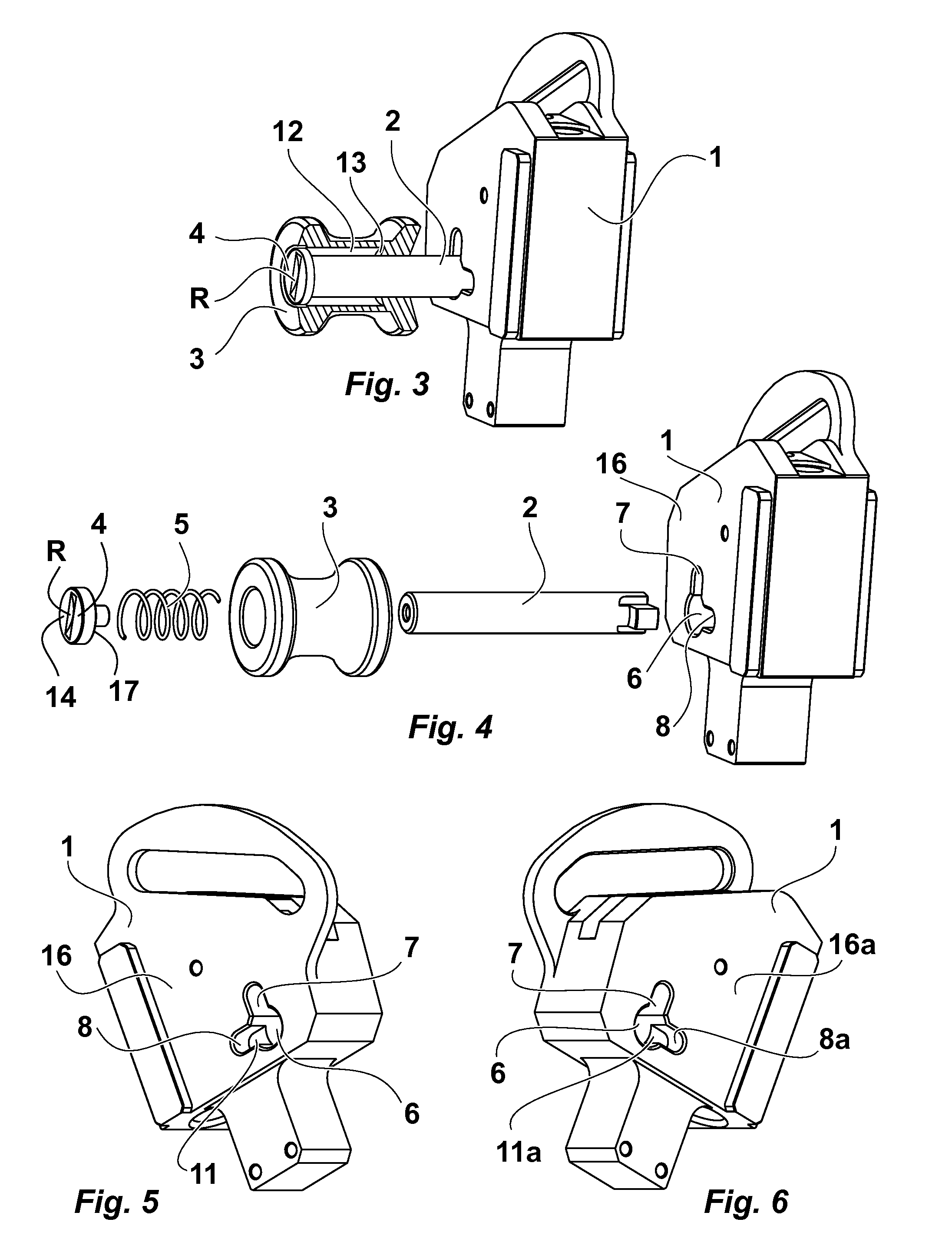

[0032]The following description is one possible and exemplary embodiment of the cocking mechanism characterizing the invention and is not exhaustive in any way. The Figures associated with this document show the constituent parts of the compound mechanism as used in an exemplary firearm: a main body or frame (A) and mobile mass (1) with a bore or tunnel (6) traversing the mobile mass (1) from one side to the other; a groove (7) tangent to the tunnel (6), two slots (8) and (8a) also arranged in the sidewalls (16) and (16a) of the mobile mass (1). This mobile mass (1) receives in the tunnel (6) an assembly referred to as the cocking lever (FIGS. 7-8) composed of a main pin (2) supporting a cocking button (3) and a return spring (5) along with a spring retention means (4). The cocking lever assembly, by the design thereof, can be mounted indiscriminately on the right or the left side of the mobile mass (1), an important point that confirms the ambidextrous use of the device. The cockin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com