Maintenance of an offshore wind farm making use of an assembly of a floating harbour ship and a plurality of shuttle vessels

a technology of shuttle vessels and wind farms, which is applied in the direction of anchoring arrangements, vessel safety, marine vessel transportation, etc., can solve the problems of inability to yield a profitable return on investment, the wind farm no longer being able to maintain the offshore wind turbine, and the disadvantage of large distances, etc., to achieve safe, efficient and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

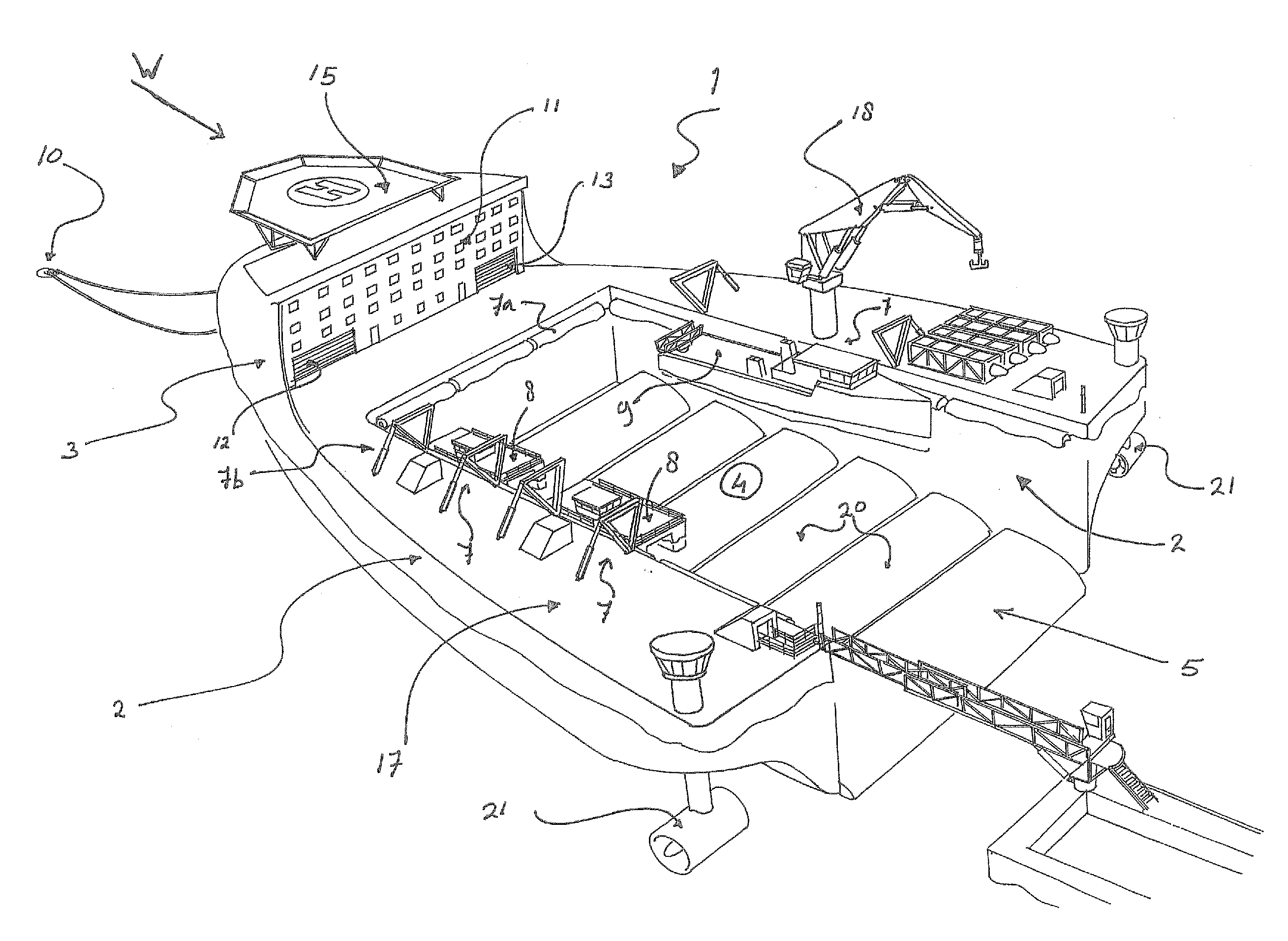

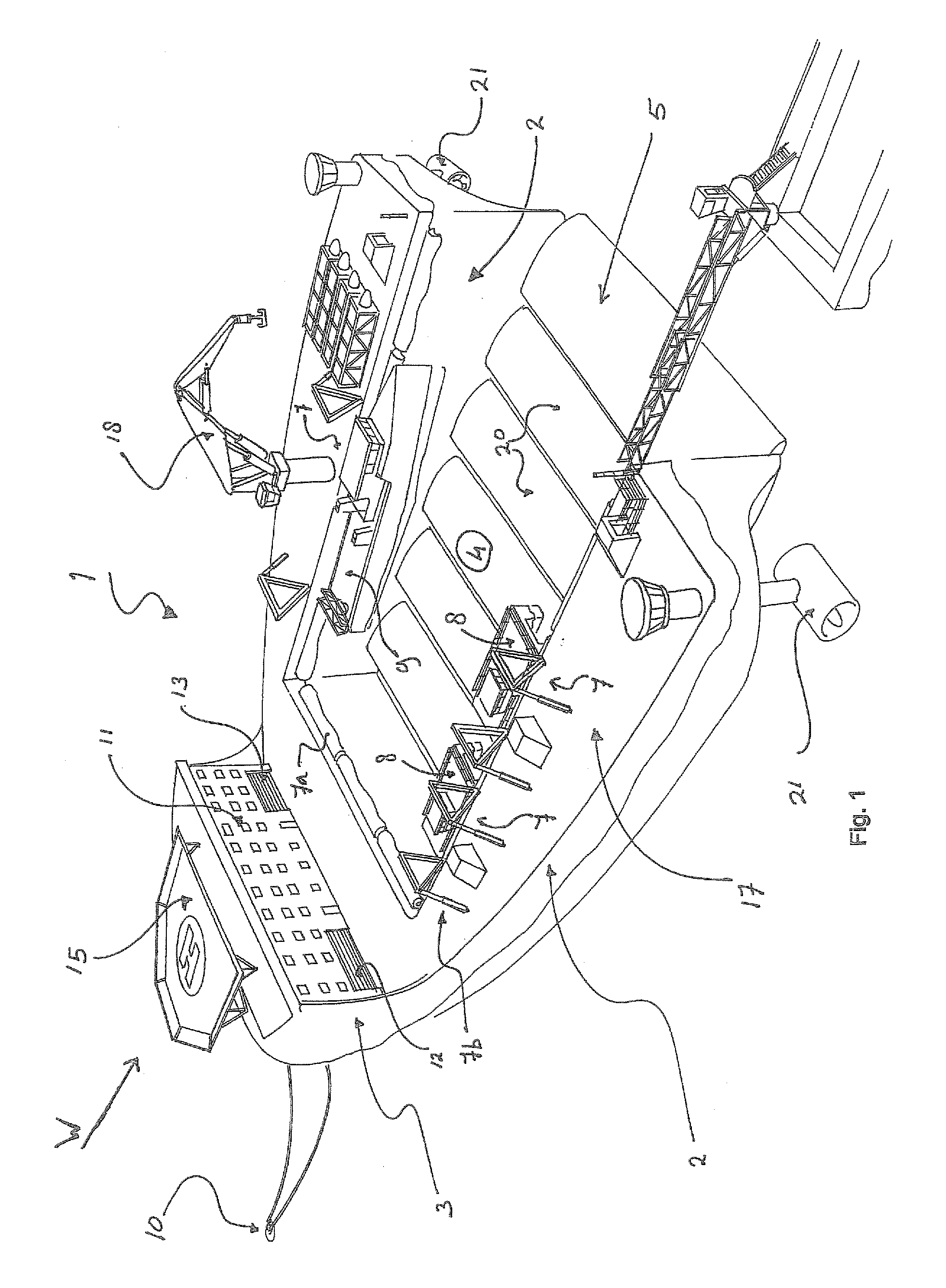

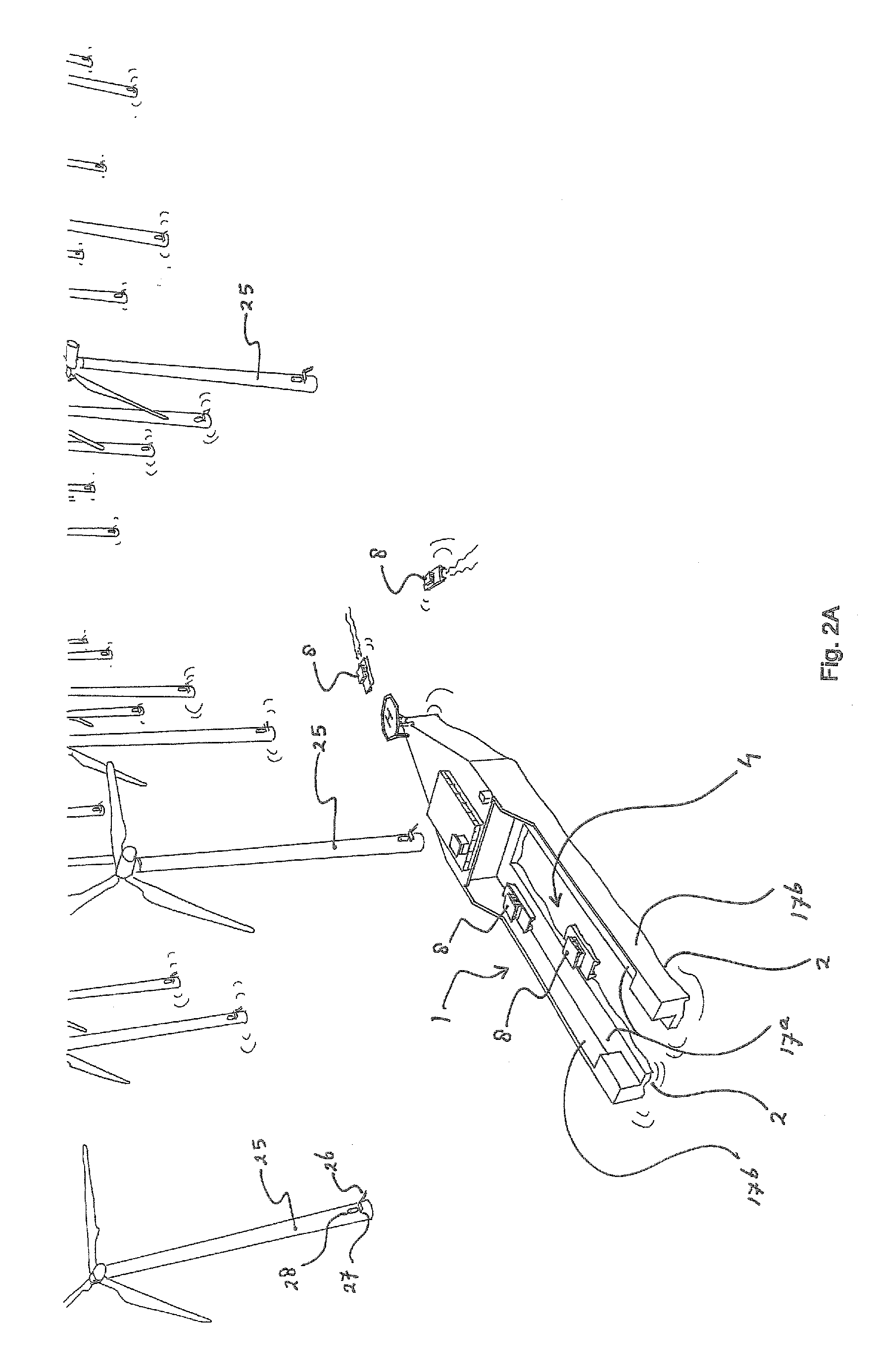

[0029]In FIG. 1 the harbour ship is indicated with the reference numeral 1. The ship 1 comprises a seaworthy floating construction with two longitudinal floating bodies 2 connected at their front sides by a bow 3. The floating bodies 2 and the bow 3 delimit respective sides of a water basin 4 spared out within the outlines of the floating construction. The basin 4 has an entrance opening 5 at the back side of the ship 1. The basin 4 is provided with mooring positions 7 alongside which fenders 7a and davits 7b are provided. At these mooring positions 7 shuttle vessels 8, 9 are moored. The shuttle vessels 8, 9 are substantially smaller than the ship 1 and the basin 4 comprises more than enough space for each of them to sail into and out of the basin 4 without bumping against each other.

[0030]The ship 1 is firmly anchored to the bottom of the sea by means of anchoring means 10. The bow 3 is provided with sleeping quarters 11 for approximately 50 to 150 man, and workplaces and storage r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com