Rapid Deployment Building System

a building system and rapid technology, applied in the direction of building roofs, roofing, building components, etc., can solve the problems of high manpower and energy consumption, unsatisfactory use of wood, and high waste level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

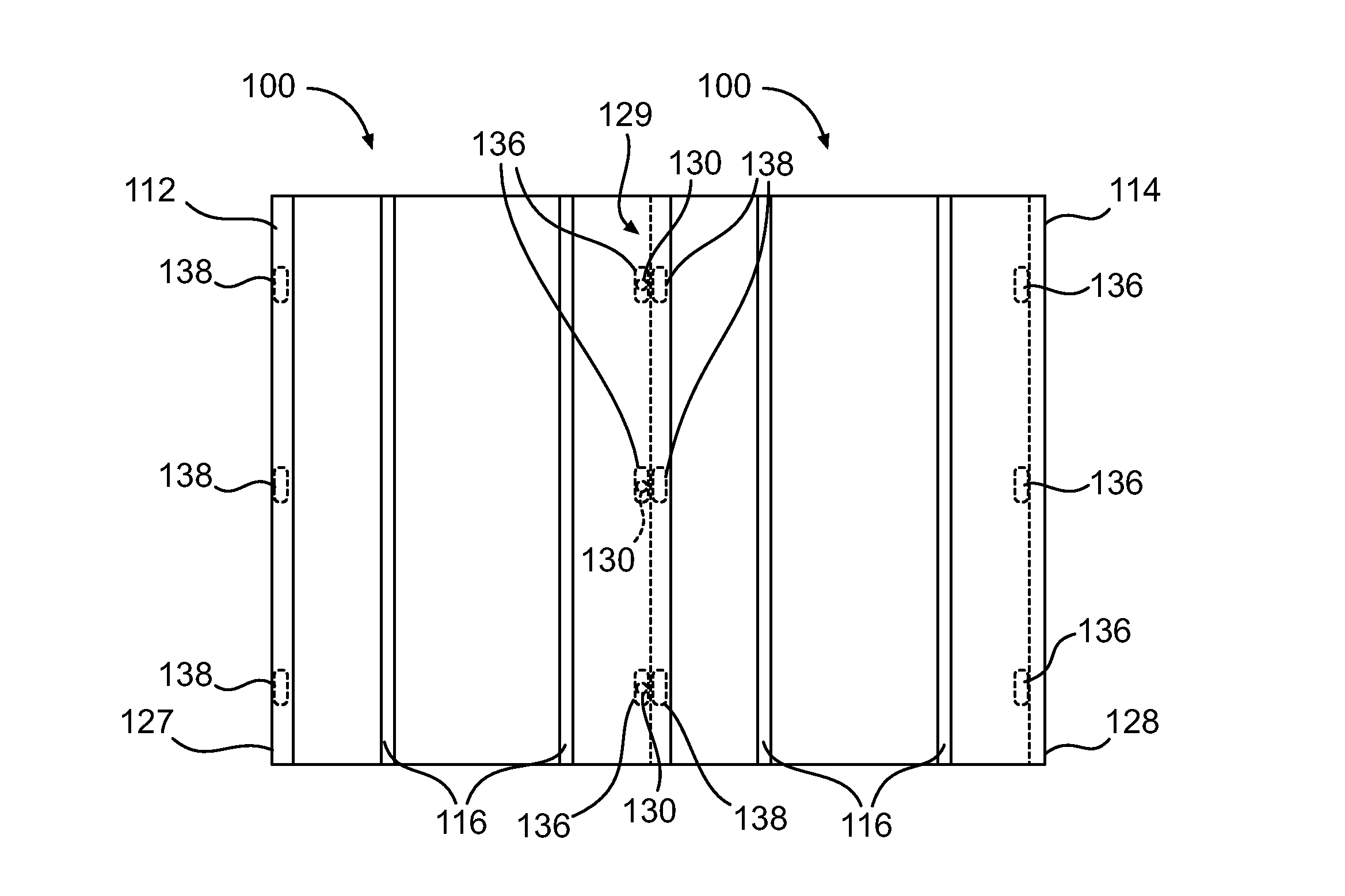

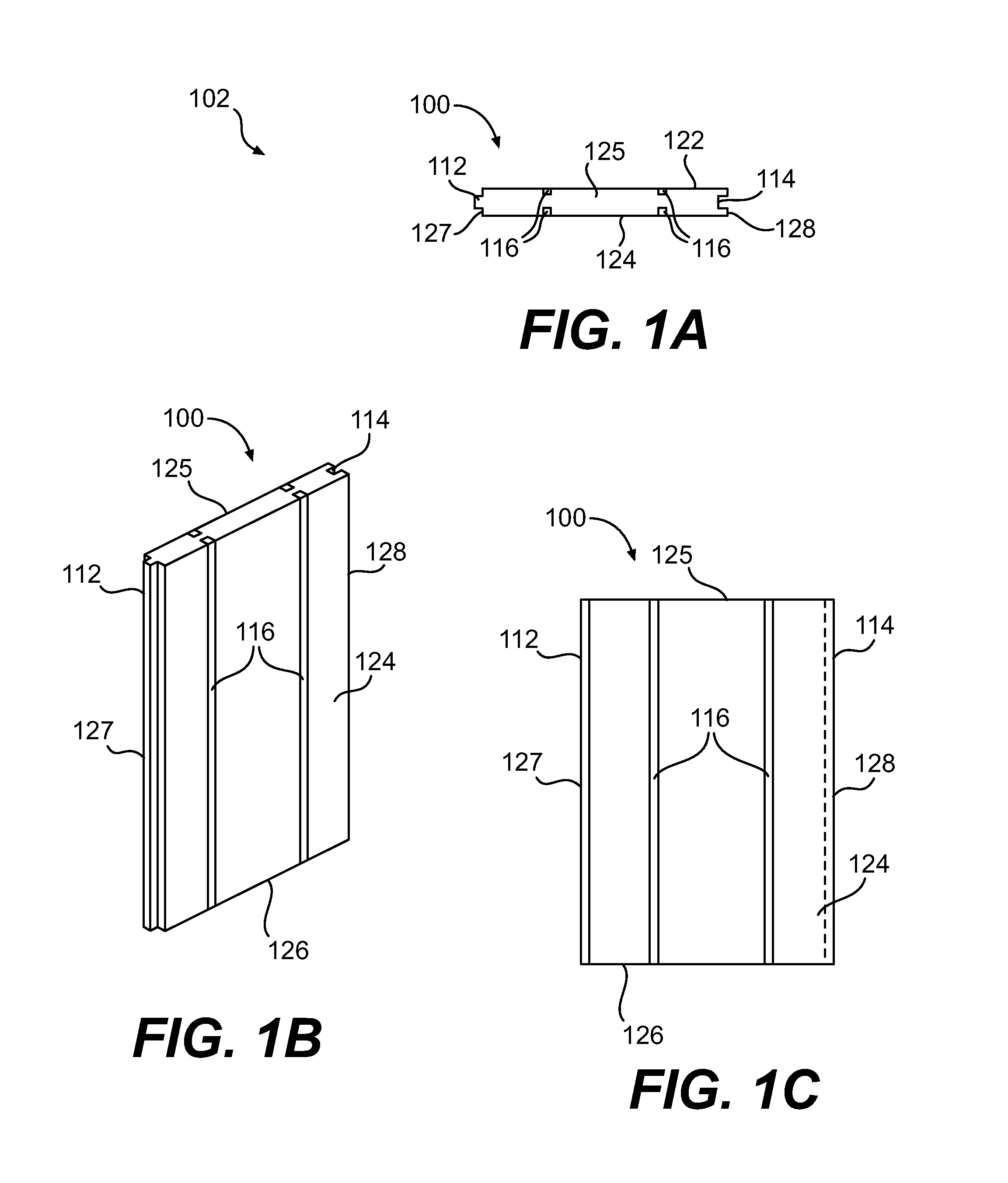

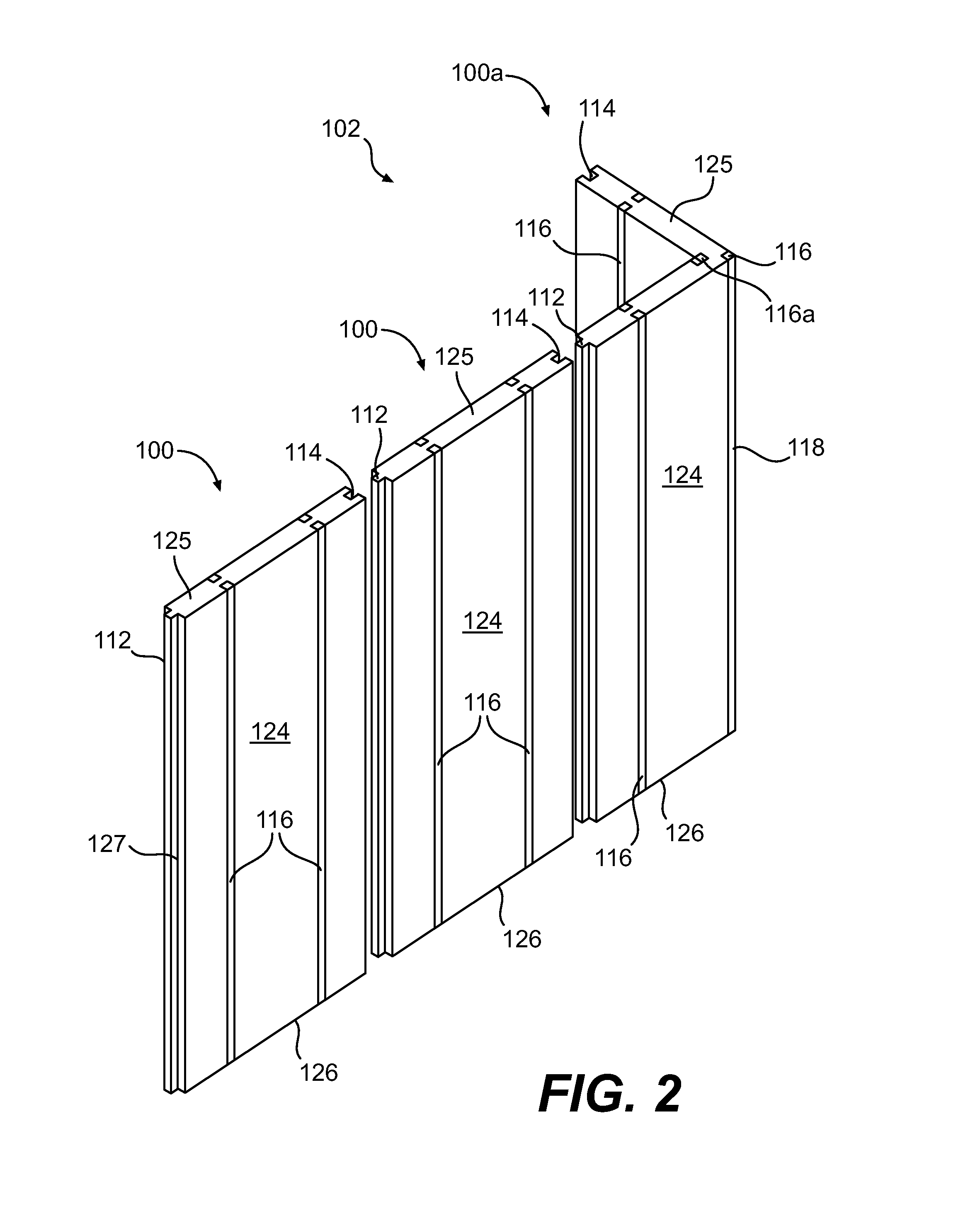

[0038]As discussed above, embodiments of the present invention relate to building components, and more particularly to panels used to form walls, floors, and roofs of buildings.

[0039]Conventional building construction materials and techniques result in a high level of waste and energy-inefficiency. Using wood to build structures reduces natural resources and much of the wood is wasted on-site as wooden pieces are cut to fit. On-site construction techniques require high labor costs and low re-use of building materials after the life of the building. There is a need in the construction industry for building components which use resources more efficiently throughout the entire construction chain, from manufacture of construction material and components, through construction of a building, throughout the useful life of a building, and by efficient recycling and reuse of materials after the building life is ended. There is also a particular need for building components for temporary stru...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com